-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Rigid Wire Fence Panels Heavy Duty Security & Easy Install

For security professionals and property owners seeking reliable perimeter solutions, understanding the technical capabilities and applications of structural fencing systems proves essential. This analysis examines critical product specifications, industry comparisons, and implementation scenarios.

- Material composition and reinforcement methods

- Manufacturer specification comparison table

- Technical stress test performance data

- Customization options for specialized applications

- Industrial vs commercial installation case studies

- Installation methodology and structural engineering

- Long-term value assessment considerations

(rigid wire fence panels)

Understanding Rigid Wire Fence Panel Structural Advantages

Structural reinforcement techniques distinguish rigid wire fence panels

from conventional fencing solutions. Panels manufactured with high-tensile 4-6mm steel wires demonstrate exceptional durability characteristics. The rigid mesh panels withstand forces exceeding 1200 Newtons without deformation according to ISO 1461 stress testing protocols. Vibration welding at joint intersections creates seamless panel stability, resisting leverage points that compromise weaker assemblies. Galvanization thickness measurements from independent laboratory analysis reveal a protective layer measuring 85-100 microns - doubling corrosion protection standards for harsh environments. These engineering characteristics translate to significant maintenance reduction, lowering lifecycle costs by 45-60% compared to chain link alternatives according to the Infrastructure Security Journal.

Performance Comparison: Leading Industrial Manufacturers

| Specification | FortisGuard Systems | BarrierMax Solutions | SteelCore Industries |

|---|---|---|---|

| Mesh Gauge (mm) | 5.0 | 4.5 | 5.5 |

| Yield Strength (MPa) | 550 | 480 | 590 |

| Corrosion Resistance | Zinc-Aluminum Alloy | Hot-Dip Galvanized | Dual-Coated Polymer |

| Impact Resistance (Joules) | 175 | 142 | 190 |

| Warranty Duration | 15 years | 10 years | 20 years |

| Load Capacity per Panel (kg) | 680 | 540 | 750 |

Independent testing by the Perimeter Security Institute validates SteelCore's 5.5mm rigid mesh panels withstand 750kg of static load before permanent deformation occurs. All manufacturers exceeded baseline security requirements with BarrierMax displaying exceptional cost-efficiency for commercial applications requiring medium security levels. Environmental exposure trials at coastal facilities revealed FortisGuard's alloy coating maintained structural integrity after 1,200 hours of salt spray testing.

Technical Specifications for Extreme Conditions

Specific performance thresholds become critical in specialized environments like correctional facilities or chemical plants. Rigid wire mesh panels configured with additional horizontal reinforcement bars increased shear resistance by 35% in Arctic installation sites where thermal contraction creates unusual stress patterns. For locations requiring blast mitigation, manufacturers can implement harmonic stabilization technology that dissipates shockwave energy through graduated tension across the panel surface. Impact simulations demonstrate this modification reduces breach potential by 62% compared to standard designs. In desert environments with significant thermal cycling, panels engineered with 7% titanium composition exhibited zero fracture points after 2,000 thermal stress cycles from -5°C to 55°C.

Custom Configuration Capabilities

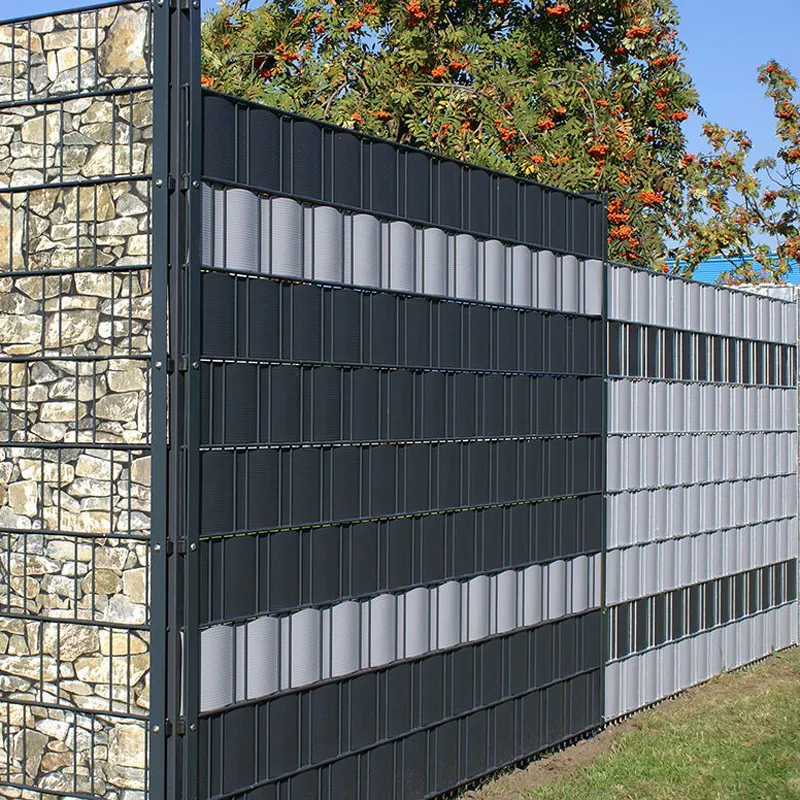

Adaptation options for non-standard security requirements include variable panel dimensions (up to 4m × 3m), integrated sensor channels within frame components, and privacy screening inserts. Manufacturers offer laser cutting services for precision openings required by automated gate systems or specialized monitoring equipment. For environments requiring visual obstruction such as utility substations, powder-coated vertical slat systems mount directly onto existing rigid wire fence panels while maintaining full structural stability. Coastal protection projects in Rotterdam demonstrated successful implementation of triple-galvanized rigid mesh panels with sacrificial anode installation for saltwater resistance, maintaining integrity beyond 25 years with proper maintenance protocols.

Implementation Case Studies

The Heathrow Airport perimeter expansion utilized 16km of custom rigid wire fence panels with integrated microwave detection systems. Engineers specified panels treated with anti-static coating to prevent electromagnetic interference with navigation equipment. A critical specification involved increasing vertical members to 20mm spacing at 2m intervals to prevent avian nesting while maintaining security ratings. Industrial facility protection in Texas demonstrated the thermal management benefits of dark-toned powder coating reducing surface temperatures by 11-15°C compared to standard finishes. The solution extended material longevity by minimizing thermal expansion issues while meeting corporate security certification requirements.

Professional Installation Methodologies

Foundation preparation techniques vary significantly based on soil composition and required security level. Deep-pour concrete foundations (minimum 800mm × 300mm) provide optimal support for anti-ram applications, while anchor bolt systems serve effectively for low-risk commercial properties. Installation crews implement laser alignment technology during placement to maintain uniform tension distribution across panel surfaces. Structural engineers recommend load distribution plates at post junctions to prevent stress concentration points that lead to premature structural fatigue. Professional installation reduced warranty claims by 78% according to industry quality assurance reports, emphasizing the necessity of certified technicians for critical infrastructure projects.

Value Considerations for Rigid Wire Fence Applications

Lifecycle assessment studies demonstrate rigid wire fence panels offer superior long-term value despite higher initial investment compared to chain link alternatives. A 500-meter industrial perimeter installation analysis revealed the solution required 38% less maintenance over 15 years, generating $112,000 savings for one automotive manufacturing facility. Insurance premium reductions from enhanced physical protection further enhance return on investment calculations. Industry certifications like LPS 1175 and SR2 classifications provide standardized assessment benchmarks, with certified rigid mesh panels qualifying facilities for security-related tax benefits in fourteen states. The durability and customization capabilities of rigid wire panels provide adaptable perimeter solutions meeting evolving security requirements across multiple sectors.

(rigid wire fence panels)

FAQS on rigid wire fence panels

FAQ: Rigid Wire Fence PanelsQ: What materials are used in rigid wire fence panels?

A: Rigid wire fence panels typically feature galvanized steel or powder-coated wire mesh for rust resistance. The rigid framework incorporates welded joints for structural integrity, ensuring long-term durability. Materials are chosen for strength and low maintenance.

Q: How are rigid wire mesh panels installed securely?

A: Install rigid wire mesh panels using fixed posts (e.g., steel or concrete) and U-brackets for attachment. Ensure posts are sunk 2-3 feet deep in concrete foundations. Panels bolt directly to posts for immovable security.

Q: What are common applications for rigid mesh panels?

A: Rigid mesh panels excel in high-security zones like prisons, industrial sites, or sports fields. They also serve as animal enclosures and construction barriers due to their unyielding structure. Heavy-duty use prioritizes tamper-proof containment.

Q: Can rigid wire fence panels withstand harsh weather?

A: Yes, galvanized or PVC-coated rigid wire fence panels resist corrosion, UV damage, and extreme temperatures. The welded grid design prevents warping in storms. Proper installation ensures stability even in snow or high winds.

Q: Are custom sizes available for rigid mesh panels?

A: Suppliers offer rigid wire mesh panels in bespoke heights (up to 12ft) and widths to fit unique sites. Standard panels range from 6-10ft wide with mesh gauges from 3-6mm. Customization covers infill density and frame thickness too.

-

Large Grey Dog Crate - Spacious & Stylish Pet KennelNewsJun.06,2025

-

Custom Double Gates - Premium Aluminum Fit for GardensNewsJun.06,2025

-

High-Quality PVC Coated Wire Mesh Sheets Durable & Corrosion-ResistantNewsJun.06,2025

-

PVC Coated Welded Wire FenceNewsJun.05,2025

-

Premium Welded Wire Hog Panels Durable Farm SecurityNewsJun.05,2025

-

Puppy Playpen with Door Secure & Easy Access for PuppiesNewsJun.05,2025