-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Coated Chicken Wire for Sale - Durable & Rust-Resistant PVC Mesh

The Strategic Advantage of Coated Hexagonal Wire Mesh in Modern Applications

In the demanding landscape of modern construction, agriculture, and industrial applications, the choice of foundational materials dictates long-term performance and cost-efficiency. Among the most versatile and robust solutions is hexagonal wire mesh, particularly when enhanced with advanced protective coatings. For B2B decision-makers and procurement specialists seeking superior durability and extended service life, understanding the intricacies of coated chicken wire for sale is paramount. This specialized netting, often referred to as stucco wire or hexagonal mesh, provides a formidable barrier against corrosion, wear, and environmental degradation, distinguishing itself from conventional wire products. Its utility spans from critical infrastructure projects to sensitive agricultural enclosures, offering both structural integrity and enhanced longevity.

This detailed guide delves into the technical aspects, manufacturing excellence, diverse applications, and economic benefits of high-quality coated hexagonal wire mesh, positioning it as a strategic investment for various industrial needs. We explore its manufacturing journey, critical technical specifications, real-world application advantages, and comprehensive after-sales support, ensuring a holistic understanding for informed purchasing decisions.

Industry Trends: The Evolution Towards Durable and Sustainable Netting Solutions

The global market for wire mesh and fencing solutions is experiencing a significant shift towards products offering enhanced durability, lower maintenance, and extended lifespans. This trend is driven by increasing environmental awareness, stringent safety regulations, and a focus on total cost of ownership rather than initial purchase price. There's a noticeable surge in demand for materials like pvc mesh manufacturers and coated wire products, as they offer superior resistance to harsh weather, chemical exposure, and biological degradation compared to their uncoated counterparts.

Specifically, the demand for vinyl and pvc coated netting is growing rapidly within the agricultural, construction, and security sectors. End-users are increasingly recognizing the long-term value in paying a premium for a product that significantly reduces replacement frequency and associated labor costs. Innovations in coating technologies, such as advanced UV stabilizers and corrosion inhibitors, further enhance the appeal of these products, ensuring color retention and structural integrity over decades. This market evolution underscores a commitment to sustainability and resilience, making products like coated chicken wire for sale a crucial component in future-proof infrastructure development.

Manufacturing Process: Precision Engineering for Lasting Performance

The production of high-quality coated chicken wire for sale is a meticulously engineered process designed to ensure peak performance and longevity. It begins with the careful selection of raw materials and culminates in rigorous quality assurance. Below is a detailed breakdown of the manufacturing flow for our High Quality Galvanized Stucco Wire Netting:

Process Flow:

- Raw Material Procurement: We utilize premium low-carbon steel wire (Q195 or Q235 grade) known for its excellent ductility and tensile strength, ensuring the foundational integrity of the mesh.

- Wire Drawing: The raw steel rods are drawn through a series of dies to achieve the precise wire gauge required for specific mesh specifications, ranging from 0.4mm to 2.0mm. This process optimizes the wire's mechanical properties.

- Hot-Dip Galvanization: The drawn wire undergoes a hot-dip galvanization process, where it is immersed in molten zinc. This creates a metallurgical bond, applying a uniform zinc coating (typically 40-60 g/m² or higher) that provides primary corrosion resistance against rust and oxidation. This step is critical for prolonging service life.

- Hexagonal Weaving: The galvanized wire is then fed into specialized weaving machines that interlock the wires to form the distinctive hexagonal mesh pattern. This design offers inherent strength, flexibility, and excellent formability for various applications.

- PVC/Vinyl Coating Application: For our premium coated products, the galvanized hexagonal mesh is subjected to a PVC or vinyl coating process. This involves either fluid bed dipping or electrostatic spraying, followed by thermal curing. The robust PVC/vinyl layer (typically 0.2mm to 0.5mm thickness) encapsulates the galvanized wire, providing an impenetrable barrier against moisture, chemicals, UV radiation, and abrasive forces. This dual protection significantly enhances corrosion resistance and extends the service life to typically 15-20 years or more, depending on environmental conditions.

- Inspection and Testing: Throughout the process, and especially after coating, the mesh undergoes rigorous quality control. This includes visual inspection for coating uniformity, adhesion tests, thickness measurements, tensile strength tests of the wire, and mesh opening conformity checks. Our products adhere to international standards such as ISO 9001 for quality management and ASTM A641/A641M for galvanized wire, ensuring consistent, high-grade output.

- Roll Slitting and Packaging: The finished coated mesh is cut into specified roll dimensions (e.g., width 0.5m-2.0m, length 10m-100m) and securely packaged for shipment, minimizing damage during transit.

Our target industries for these robust meshes include construction (stucco and plaster reinforcement), agriculture (poultry enclosures, garden fencing), landscaping (erosion control), and light industrial uses. The emphasis on high-quality materials and multi-stage protection results in products offering superior corrosion resistance and significantly reduced maintenance requirements, translating to long-term energy and cost savings for our clients.

Figure 1: Manufacturing process of PVC coated hexagonal wire mesh.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications is crucial for selecting the appropriate coated chicken wire for sale for your project. Our galvanized stucco wire netting is engineered to meet rigorous performance criteria, ensuring reliability and longevity.

Product Specification Table: Galvanized & PVC Coated Hexagonal Wire Mesh

| Parameter | Specification Range | Unit/Description |

|---|---|---|

| Material | Low Carbon Steel (Q195/Q235) | ASTM A641/A641M compliant |

| Wire Gauge (BWG) | 18 BWG to 27 BWG | (0.6mm to 1.2mm nominal wire diameter) |

| Mesh Size (Aperture) | 1/2 inch to 2 inches | (13mm to 50mm hexagonal openings) |

| Zinc Coating Weight | Min. 40 g/m² - Max. 60 g/m² | Hot-dip galvanized |

| PVC/Vinyl Coating Thickness | 0.2mm to 0.5mm | (Applied over galvanized wire) |

| Tensile Strength | 380-550 N/mm² | (Based on core wire) |

| Roll Width | 0.5m to 2.0m (1.6ft to 6.6ft) | Customizable widths available |

| Roll Length | 10m to 100m (33ft to 330ft) | Customizable lengths available |

| Coating Adhesion | Excellent (no cracking/peeling) | Tested per industry standards |

| UV Resistance | High | Prevents fading and degradation |

| Corrosion Resistance | Superior | Salt spray test results > 1000 hrs |

| Service Life | 15-20+ Years | Dependent on environmental conditions |

These specifications highlight the robust nature of our products, engineered for resilience against environmental stressors and mechanical forces. The dual-layer protection of galvanization and PVC/vinyl coating provides unmatched performance, reducing the need for frequent replacements and minimizing project downtime.

Key Technical Advantages: Why Coated Mesh Outperforms

The decision to invest in coated chicken wire for sale over standard galvanized options is driven by several critical technical advantages that translate directly into operational efficiency and cost savings.

- Superior Corrosion Resistance: The primary advantage is the multi-layered protection. The hot-dip galvanized layer provides cathodic and barrier protection against rust. The outer PVC or vinyl coating acts as an additional, impenetrable shield against moisture, salt spray, acids, alkalis, and other corrosive agents. This dual defense significantly extends the material's lifespan, particularly in coastal, industrial, or agricultural environments where bare metal would rapidly degrade. Our products consistently exceed 1000 hours in accelerated salt spray tests, far surpassing typical galvanized alternatives.

- Extended Service Life: With enhanced corrosion resistance, coated meshes achieve a service life of 15-20 years, often exceeding 25 years in benign conditions. This dramatically reduces the total cost of ownership (TCO) by minimizing replacement frequency, labor costs for installation, and material procurement cycles. For example, a standard galvanized mesh might last 5-10 years in corrosive environments, requiring twice as many replacements over the same period.

- Enhanced Aesthetics and Low Maintenance: The PVC/vinyl coating is available in various colors (e.g., green, black, white), allowing for better integration into specific landscapes or architectural designs. The smooth, non-porous surface resists dirt accumulation and is easy to clean, requiring minimal maintenance. This is a significant factor in commercial and public-facing applications.

- UV and Weathering Resistance: High-grade PVC/vinyl coatings incorporate UV stabilizers, preventing material degradation, cracking, and color fading when exposed to prolonged sunlight. This ensures the mesh maintains its structural integrity and aesthetic appeal even in extreme climatic conditions.

- Improved Handling and Safety: The smooth plastic coating eliminates sharp edges, making installation safer and reducing the risk of injuries to personnel or livestock. This is particularly beneficial in agricultural settings for poultry enclosures or pet fencing.

- Environmental Resilience: The PVC coating acts as an effective insulator against electrical currents, adding a layer of safety for certain applications. It also provides a buffer against minor impacts and abrasions, further protecting the underlying steel.

These advantages position coated hexagonal wire mesh as a superior choice for long-term, high-performance applications, offering a compelling return on investment for discerning clients.

Application Scenarios Across Diverse Industries

The versatility of coated chicken wire for sale makes it an indispensable material across a broad spectrum of industries, providing durable and cost-effective solutions for various containment, reinforcement, and protection needs.

-

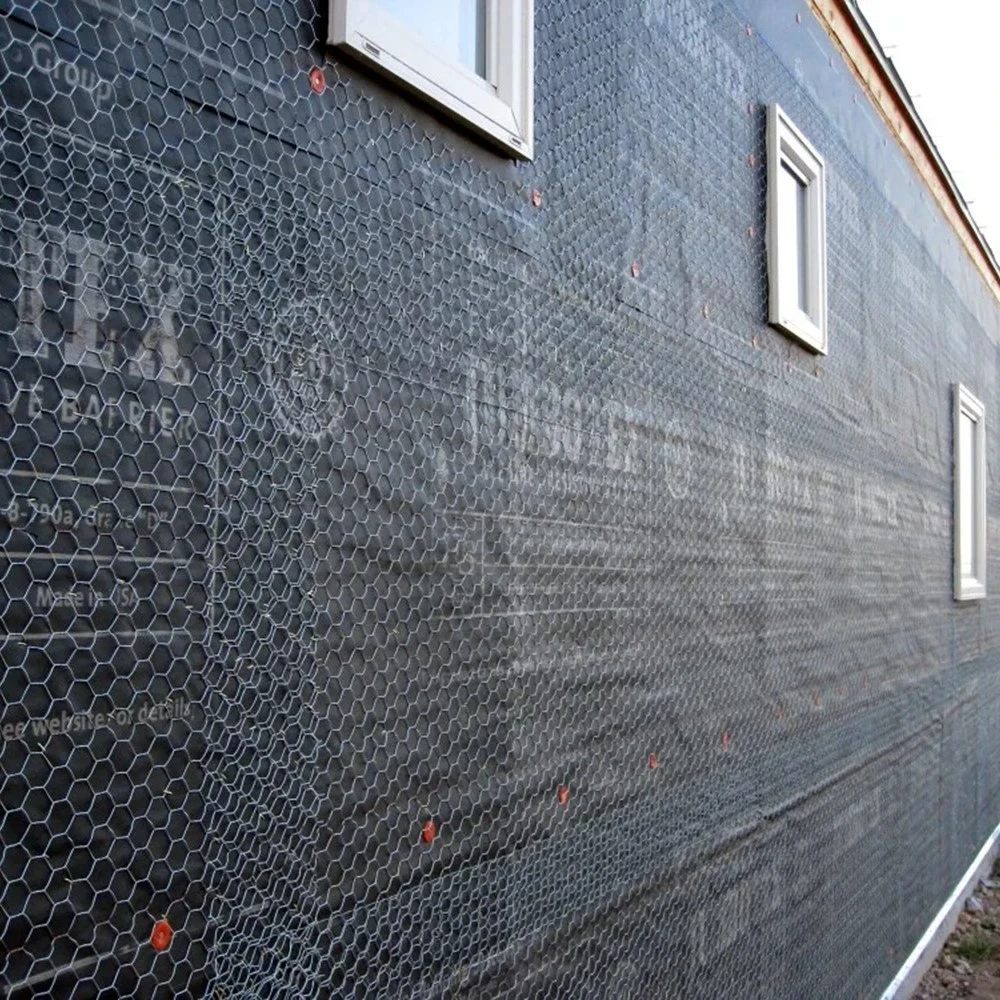

Construction & Infrastructure:

As 'stucco wire netting' or 'stucco mesh,' it serves as crucial reinforcement for plaster, stucco, and concrete walls, preventing cracking and enhancing structural integrity. Its flexibility allows it to conform to various surfaces, making it ideal for both interior and exterior applications. It's also utilized for temporary fencing on construction sites, offering a robust and reusable barrier. The corrosion resistance is particularly vital in external applications where exposure to moisture and weather elements is constant.

-

Agriculture & Poultry Farming:

The mesh size of hexagonal wire is perfectly suited for building secure and humane enclosures for poultry, rabbits, and other small animals. The PVC coating prevents injuries to animals from sharp wire edges and withstands agricultural chemicals and animal waste, contributing to a longer lifespan. This is where products like pvc chicken mesh price become highly competitive due to their long-term value.

-

Landscaping & Garden Fencing:

For garden protection, perimeter fencing, and decorative landscape elements, coated hexagonal wire mesh offers both functionality and aesthetic appeal. It guards against pests, supports climbing plants, and defines garden spaces without detracting from the natural environment, especially when using green PVC coatings. Its robust nature makes it an excellent alternative to standard pvc chain link fence price where finer mesh is needed.

-

Erosion Control & Gabion Baskets:

Heavier gauge PVC coated hexagonal mesh is increasingly used in gabion baskets for retaining walls, riverbank protection, and erosion control. The coating provides exceptional resistance to water, soil, and environmental stressors, ensuring the long-term stability of civil engineering projects. For large-scale projects, factors like pvc coated chain link fence price and vinyl coated chain link fence cost become significant considerations.

-

Pet Enclosures & Residential Fencing:

Its safety features and durability make it an excellent choice for creating safe, long-lasting enclosures for pets in residential settings. The appealing colors and low maintenance also contribute to its popularity for various home and garden applications.

Figure 2: Diverse applications of coated hexagonal wire mesh.

Vendor Comparison: Selecting a Reliable Manufacturer

When sourcing coated chicken wire for sale, comparing vendors is crucial. The market offers various options, but not all suppliers deliver the same level of quality, service, and technical support. Below is a comparative overview of key factors to consider:

Key Vendor Comparison Parameters

| Feature | Standard Supplier | Peilingtech (Example of Premium Vendor) |

|---|---|---|

| Certifications & Standards | Basic production standards, few external certifications. | ISO 9001:2015, ASTM A641/A641M, CE compliant. Rigorous internal QC. |

| Material Quality | Varied steel grades, thinner zinc/PVC coatings. | Premium Q195/Q235 steel, optimized hot-dip galvanization (40-60g/m²), robust PVC/vinyl (0.2-0.5mm). |

| Coating Adhesion & UV Resistance | Prone to peeling/cracking, faster UV degradation. | Excellent bond strength, integrated UV inhibitors for long-term color stability. |

| Service Life (Estimated) | 5-10 years (avg. conditions). | 15-20+ years (avg. conditions), validated through extensive testing. |

| Customization Options | Limited standard sizes/colors. | Wide range of wire gauges, mesh sizes, roll dimensions, coating colors. Engineering support for custom projects. |

| Lead Time & Fulfillment | Variable, often longer for specialized orders. | Efficient production, flexible logistics, global shipping capabilities. Clear lead time commitments. |

| Warranty & After-Sales Support | Basic or limited warranty, minimal support. | Comprehensive product warranty, dedicated technical support, quick response to inquiries. |

Peilingtech, for instance, emphasizes stringent quality control and adherence to international standards, building long-term partnerships through reliable products and responsive customer service. Our dedication to superior material science and manufacturing precision sets us apart, offering a distinct competitive advantage for clients requiring high-performance, durable netting solutions.

Customized Solutions and Design Flexibility

Recognizing that every project presents unique challenges, we specialize in providing customized solutions for coated chicken wire for sale. Our manufacturing capabilities allow for extensive design flexibility, ensuring that clients receive products perfectly tailored to their specific technical requirements and application environments.

- Wire Gauge & Mesh Size: We offer a wide range of wire diameters (from fine 27 BWG to heavier 18 BWG) and mesh apertures (1/2-inch to 2-inch hexagonal openings) to meet diverse needs, from delicate garden protection to robust construction reinforcement.

- Coating Type & Thickness: While PVC is standard, we can discuss other polymer coatings for specialized chemical or temperature resistance. Coating thickness can be adjusted to enhance durability for extreme conditions.

- Color Options: Beyond standard green and black, custom color matching is available for projects requiring specific aesthetic integration, branding, or visibility requirements.

- Roll Dimensions: Custom roll widths (e.g., narrow strips for specific applications or extra-wide rolls for large-scale fencing) and lengths (from short rolls for retail to bulk rolls for industrial clients) can be produced to minimize waste and optimize installation efficiency.

- Material Composition: While standard steel is primary, specific projects might benefit from different base metals or specialized galvanization techniques (e.g., higher zinc content) to meet unique environmental demands.

Our engineering team collaborates closely with clients from conceptualization to deployment, providing technical consultation and prototyping services. This client-centric approach ensures optimal product performance and maximum value, even for the most complex project specifications.

Figure 3: Customization options available for industrial fencing solutions.

Real-world Application Case Studies

The proven performance of our coated hexagonal wire mesh is best illustrated through successful application case studies that highlight its durability, adaptability, and economic benefits.

Case Study 1: Large-Scale Poultry Farm Expansion, Midwest USA

- Challenge: A major poultry producer needed to expand their free-range chicken enclosures rapidly. The existing galvanized mesh suffered from premature corrosion due to constant exposure to moisture and ammonia from chicken waste, requiring frequent repairs and replacements every 3-5 years. This led to high maintenance costs and potential escape risks.

- Solution: We supplied 5,000 linear meters of 1-inch, 20 BWG PVC coated chicken mesh in a custom green color. The galvanized core provided initial protection, while the robust PVC layer offered superior resistance to the harsh chemical environment and physical wear.

- Outcome: After 7 years in service, the PVC coated mesh shows negligible signs of corrosion or degradation. The farm reported a 70% reduction in fencing maintenance costs and improved animal welfare due to the smooth, non-abrasive surface. The projected service life is estimated to exceed 18 years, providing a significant return on investment compared to previous solutions.

Case Study 2: Coastal Residential Stucco Reinforcement, Florida, USA

- Challenge: A construction firm building luxury homes along the Florida coast required a stucco reinforcement mesh capable of withstanding extreme humidity, salt-laden air, and hurricane-force winds. Previous projects using standard galvanized stucco mesh often exhibited rust bleed-through and premature material failure within 5 years.

- Solution: We provided our High Quality Galvanized Stucco Wire Netting (1-inch mesh, 22 BWG, 0.4mm PVC coating) specifically designed for robust corrosion resistance in marine environments.

- Outcome: The mesh was installed on over 20 residential units. After 10 years, independent inspections confirmed no signs of rust, delamination, or structural compromise in the stucco. The PVC coating effectively shielded the galvanized core from the corrosive coastal environment, ensuring the aesthetic and structural integrity of the buildings. The client noted that while the initial pvc stucco wire mesh price was higher, the elimination of costly repairs and repainting translated into substantial long-term savings and enhanced homeowner satisfaction.

Figure 4: Coated stucco wire mesh providing durable wall reinforcement.

Ensuring Trust and Reliability: Your Partner in Durable Netting Solutions

At Peilingtech, we understand that trust is built on transparency, robust support, and unwavering commitment to quality. Our approach to providing coated chicken wire for sale extends beyond product delivery to encompass comprehensive pre-sales and after-sales service.

Frequently Asked Questions (FAQ)

- Q1: What is the primary benefit of PVC coating over just galvanization?

- A1: PVC coating provides an additional, highly effective barrier against moisture, chemicals, UV radiation, and physical abrasion. This dual protection significantly extends the service life, especially in corrosive or harsh environments, and offers aesthetic benefits.

- Q2: What is the typical lead time for a standard order?

- A2: For standard product configurations and quantities, our lead time typically ranges from 10 to 20 business days, depending on current production schedules. Custom or large-volume orders may require slightly longer, which will be communicated transparently during the quotation phase.

- Q3: Can your coated wire mesh be used in marine environments?

- A3: Absolutely. Our PVC/vinyl coated galvanized wire mesh is specifically designed with superior corrosion resistance, making it ideal for coastal and marine applications where salt spray and high humidity are prevalent. The coating provides an extra layer of defense against chlorides.

- Q4: What are your warranty commitments?

- A4: We offer a comprehensive 5-year limited warranty against manufacturing defects and premature coating degradation under normal use and installation. Specific project warranties for extended durations can be discussed based on volume and application. Our commitment underscores our confidence in product quality and durability.

- Q5: How do I get technical support or assistance with product selection?

- A5: Our dedicated customer support and technical sales teams are available to assist with product selection, technical specifications, and custom inquiries. You can reach us via phone, email, or through our website's contact form. We aim for a response within 24 business hours.

Lead Time and Fulfillment

With state-of-the-art manufacturing facilities and optimized logistics, we ensure efficient order processing and timely delivery. Our substantial production capacity allows us to fulfill large-volume orders while maintaining stringent quality control. We provide detailed shipping estimates and tracking information for all consignments, ensuring transparency from production to final delivery. Our global distribution network facilitates reliable shipments to diverse international markets.

Warranty Commitments and Customer Support

We stand behind the quality of our products with robust warranty provisions, reflecting our confidence in their durability and performance. Our after-sales support extends to technical assistance, installation guidance, and prompt resolution of any product-related concerns. Our goal is to forge lasting partnerships by providing not just products, but complete, reliable solutions.

Conclusion

The strategic integration of high-quality, coated chicken wire for sale into modern industrial and agricultural projects represents a smart investment in durability, cost-efficiency, and long-term performance. By combining the intrinsic strength of galvanized steel with the protective resilience of advanced PVC/vinyl coatings, these products offer unparalleled resistance to corrosion, environmental degradation, and wear. From essential stucco reinforcement in construction to secure and humane enclosures in agriculture, the technical advantages and application versatility of coated hexagonal wire mesh are undeniable. Choosing a reputable manufacturer like Peilingtech ensures access to superior materials, precise engineering, comprehensive customization, and unwavering support, empowering businesses to build more resilient and sustainable infrastructures for the future.

Authoritative References

- ASTM International. (2020). ASTM A641/A641M - 19, Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire. ASTM International, West Conshohocken, PA.

- International Organization for Standardization. (2015). ISO 9001:2015, Quality management systems — Requirements. ISO, Geneva, Switzerland.

- The Galvanizers Association. (2023). Hot Dip Galvanizing and Corrosion Protection. Available at: [Industry publications and technical guides on galvanization].

- Vinyl Institute. (2022). PVC and its applications in durable goods. Available at: [Material science journals and industry white papers on PVC/vinyl coatings].

- Stucco Manufacturers Association. (2021). Stucco Reinforcement Mesh Best Practices. Available at: [Construction material guidelines and association resources].

-

Stylish Wooden Dog Crates For Sale - Furniture-Quality & SecureNewsAug.26,2025

-

Steel Fence Posts for Sale - Durable & Affordable OptionsNewsAug.21,2025

-

Durable Ornate Garden Gates: Steel Single/Double Wrought IronNewsAug.19,2025

-

Durable Dog Playpen with Waterproof Bottom - Easy Clean & SafeNewsAug.18,2025

-

New Large Metal Dome Top Chicken Coop Pen Dog Duck KennelNewsAug.17,2025