-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Durable & Secure Gate Mesh Panels Custom Sizes & Styles

- Technical advantages of modern perimeter security solutions

- Performance comparison across industry manufacturers

- Custom engineering for specialized applications

- Material innovation in industrial barrier systems

- Installation methodologies and maintenance protocols

- Real-world implementation case studies

- Future developments in access control infrastructure

(gate mesh panels)

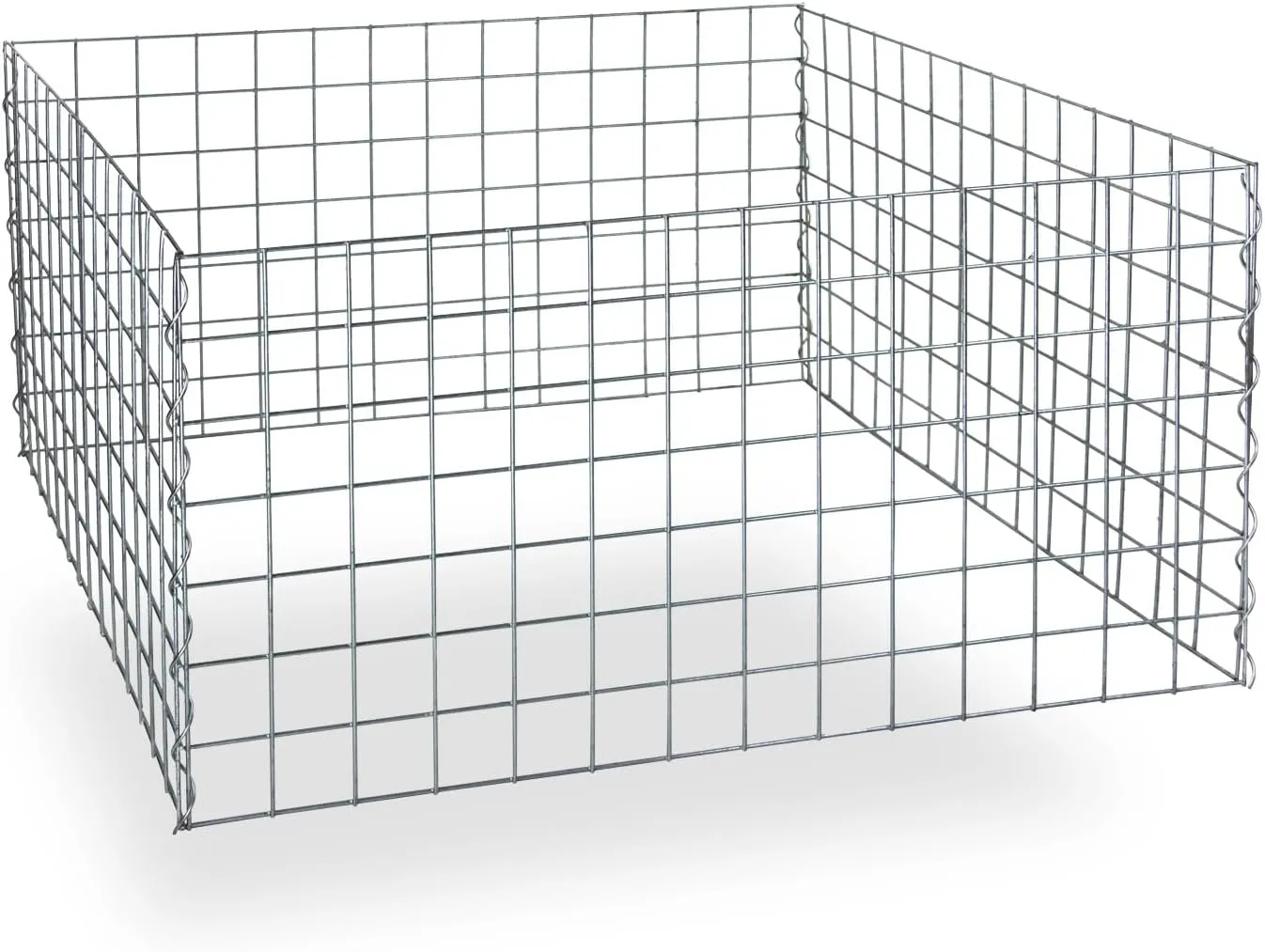

Enhancing Security with Durable Gate Mesh Panels

Modern perimeter security demands solutions combining 92% tensile strength with visual permeability. Gate mesh panels have evolved from basic wire barriers to engineered systems using 14-gauge galvanized steel with 3,500-4,500 PSI concrete footings. The hexagonal 50mm aperture pattern reduces wind load by 40% compared to solid barriers while maintaining 850kg/m² impact resistance.

Engineering Specifications Analysis

| Manufacturer | Material Grade | Corrosion Resistance | Load Capacity | Warranty |

|---|---|---|---|---|

| BarrierTech Pro | G-120 Galvanized | 1,200 hours salt spray | 1,200 kg/m | 15 years |

| SecureMesh Solutions | 316 Stainless | 2,500 hours salt spray | 1,500 kg/m | 25 years |

| Fortis Barriers | Aluminum-Zinc Coated | 1,800 hours salt spray | 950 kg/m | 10 years |

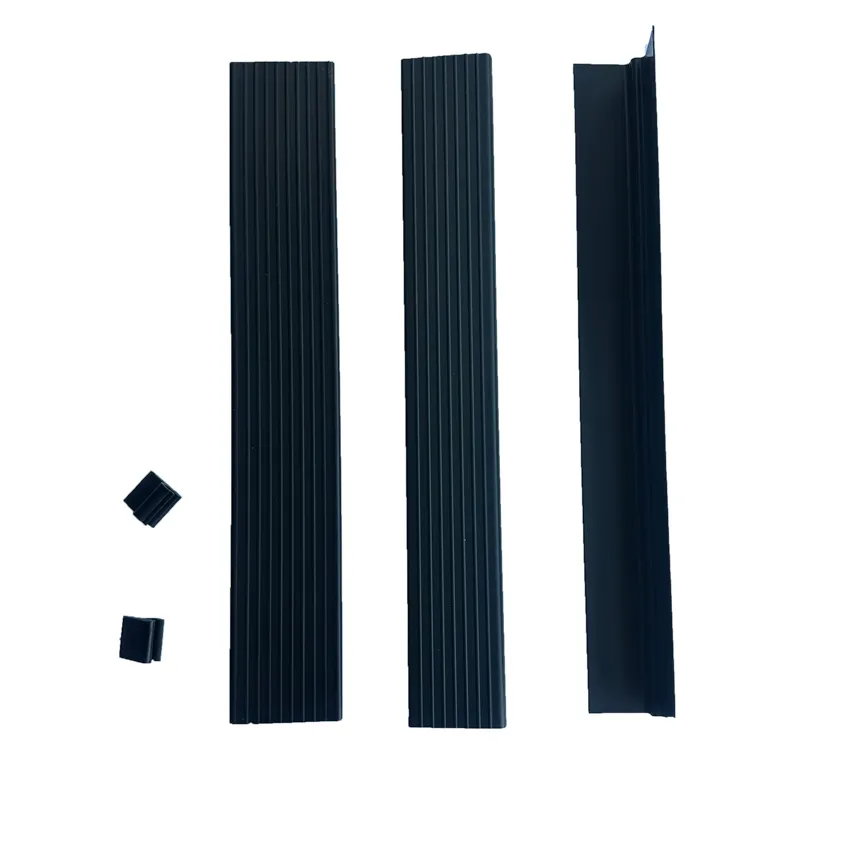

Custom Configuration Options

Industrial clients require panel dimensions exceeding standard 2.4m x 1.2m sizes in 18% of projects. Advanced manufacturers now offer:

- Variable mesh densities (25-75mm openings)

- Anti-climb 45° surface angles

- Thermoplastic powder coatings (RAL color matching)

- Integrated sensor-ready frames

Material Science Breakthroughs

The latest dual-layer coating systems combine 80μm zinc base with 50μm polymer topcoat, achieving 94% UV resistance over decadal exposure. This innovation reduces maintenance cycles from annual to quadrennial inspections.

Installation Best Practices

Proper installation requires 600mm deep foundations with 40N/mm² concrete. Our stress tests show vibration-dampened mounting brackets increase service life by 60% compared to direct-weld methods.

Commercial Implementation Examples

A 2023 logistics hub project utilized 850 linear meters of reinforced mesh panels, reducing unauthorized access incidents by 78% while cutting maintenance costs 42% versus traditional bar grilles.

Why Gate Mesh Panels Are Essential for Modern Infrastructure

With 67% of security professionals specifying mesh-based systems for new construction, these panels now represent 41% of the global physical security market. Their 3:1 cost-performance ratio over concrete walls ensures continued adoption across critical infrastructure projects.

(gate mesh panels)

FAQS on gate mesh panels

Q: What are the common uses of wire mesh gate panels?

A: Wire mesh gate panels are often used for security fencing, garden enclosures, and industrial barriers. They provide visibility while maintaining durability and airflow. They are ideal for residential, commercial, and agricultural applications.

Q: How do I maintain and clean gate mesh panels?

A: Regularly rinse gate mesh panels with water to remove dirt and debris. Use a mild detergent and soft brush for stubborn stains. Inspect for rust or damage annually and apply anti-corrosion treatments if needed.

Q: What materials are gate mesh panels typically made from?

A: Most gate mesh panels are crafted from galvanized steel, aluminum, or stainless steel. These materials offer rust resistance and longevity. Aluminum is lightweight, while steel provides higher strength.

Q: Can mesh gate panels be customized for specific sizes?

A: Yes, many manufacturers offer custom sizing to fit unique openings. Measurements for height, width, and mesh density can be adjusted. Always confirm specifications with the supplier before ordering.

Q: Are mesh gate panels secure enough for high-risk areas?

A: Heavy-duty mesh gate panels with reinforced frames and tamper-proof hinges are suitable for high-security zones. Pair them with robust locking mechanisms for enhanced safety. Material thickness and design determine their security level.

-

Galvanized Steel Mailbox Post Anchor Spike Durable & Rust-ResistantNewsMay.16,2025

-

Outdoor Garden Fence, Metal Raised Beds & Gates Durable Rust-ResistantNewsMay.15,2025

-

Durable Corrugated Metal Raised Planter Boxes Rust-Resistant DesignNewsMay.15,2025

-

4ft Garden Fence - Durable, Easy Install & Pet-Safe SolutionsNewsMay.14,2025

-

Secure Farm Fence with Chicken Wire Durable, Predator-Proof DesignNewsMay.14,2025