-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

Best Grape Trellis for Sale | Durable Metal Fruit Support

Driving Agricultural Efficiency with Advanced Trellis Systems

In modern horticulture and viticulture, the optimization of plant growth and yield is paramount. Advanced support structures play a critical role in achieving these objectives. Our focus today is on high-quality grape trellis for sale, designed to meet the rigorous demands of commercial agricultural operations. These robust systems extend beyond simple plant support, functioning as essential infrastructure for maximizing crop health, improving air circulation, and facilitating efficient harvesting. The right trellis system can significantly impact operational costs, crop quality, and overall profitability for B2B stakeholders in farming and agricultural management.

The demand for durable and efficient grape trellis for sale solutions is growing, driven by innovations in agricultural technology and a global push for sustainable farming practices. Investing in superior fruit support systems is a strategic decision for any commercial grower aiming for long-term success and increased yield per hectare.

Industry Trends in Advanced Plant Support Systems

The agricultural sector is witnessing a significant shift towards more resilient, sustainable, and technologically integrated plant support solutions. Key trends include:

- Durability and Longevity: A strong preference for materials like galvanized steel and UV-stabilized polymers that offer extended service life, reducing replacement cycles and maintenance costs.

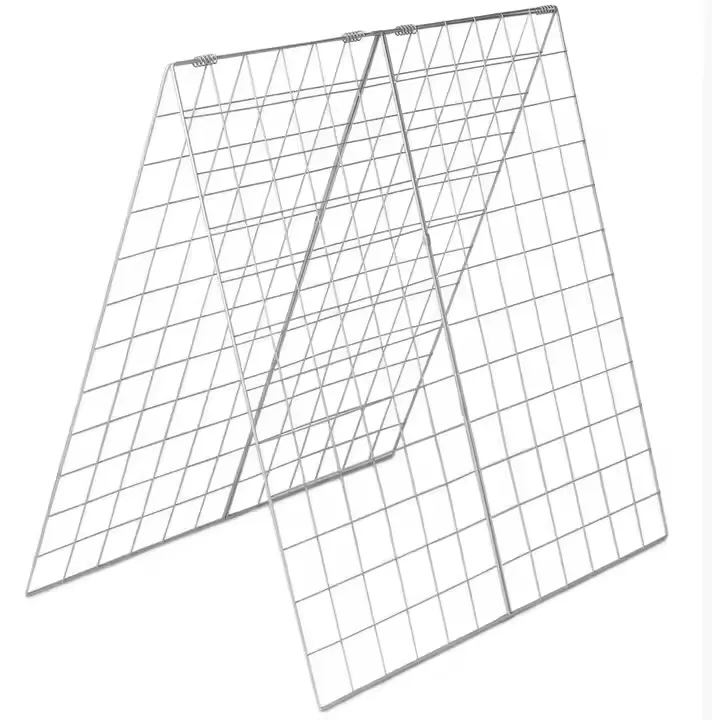

- Modularity and Scalability: Systems designed for easy expansion, reconfiguration, and adaptability to different crop types and growth stages, crucial for diverse agricultural operations.

- Ergonomics and Automation Compatibility: Designs that facilitate easier manual harvesting and pruning, as well as integration with automated systems for spraying, monitoring, and mechanical harvesting.

- Sustainability: Emphasis on materials that are recyclable or have a lower environmental footprint, coupled with designs that promote efficient water and nutrient usage by plants.

- Enhanced Crop Health: Structures engineered to optimize air circulation and sunlight exposure, minimizing disease risk and maximizing photosynthetic efficiency for crops supported by a quality fruit trellis.

These trends highlight a move from basic vegetable plant support to sophisticated engineering solutions that contribute directly to higher yields and operational efficiencies.

Manufacturing Process of High-Performance Trellis Systems

The production of commercial-grade trellises, such as the Garden Plant Climbing Grid Trellis Long Bean Cucumber Trellis, involves precision engineering and adherence to stringent quality controls. Our manufacturing process ensures that each metal vegetable trellis meets or exceeds industry standards for durability and performance.

Key Stages of Production:

- Material Sourcing & Preparation: We utilize high-grade carbon steel or stainless steel, selected for its tensile strength and workability. Raw materials undergo rigorous inspection to ensure compliance with ASTM A36/A53 standards for structural steel. This foundational step is critical for the integrity of the finished planting trellis.

- Precision Cutting & Forming: Advanced CNC laser cutting and automated bending machines are employed to achieve precise dimensions and angles. This reduces material waste and ensures consistent product geometry, essential for easy assembly and structural stability.

- Welding & Assembly: Components are joined using robotic MIG/TIG welding processes, ensuring strong, clean welds free from defects. Each weld seam is inspected for penetration and structural integrity.

-

Surface Treatment (Corrosion Resistance):

- Hot-Dip Galvanization: Components are immersed in molten zinc, creating a metallurgical bond that provides superior corrosion resistance. This process adheres to ISO 1461 and ASTM A123 standards, ensuring a uniform, durable zinc coating capable of protecting the fruit support frames for decades in harsh outdoor environments.

- Powder Coating: For additional aesthetic appeal and enhanced protection, electrostatically applied polymer powder is cured onto the galvanized surface, forming a tough, chip-resistant layer. This process is often chosen for specialized applications or where specific aesthetics are required.

-

Quality Control & Testing: Each batch undergoes rigorous testing, including:

- Dimensional checks using calibrated equipment.

- Coating thickness verification (e.g., via magnetic induction probes for galvanization).

- Load-bearing capacity tests simulating extreme weather conditions and crop weight.

- Visual inspection for any surface defects or structural inconsistencies.

- Packaging & Shipment: Products are carefully packaged to prevent damage during transit, typically using robust crating or palletization, ready for global distribution.

This meticulous process ensures a service life of 20+ years for our galvanized products, even in demanding agricultural environments, making our grape trellis for sale a durable investment for vineyards and commercial farms.

Technical Specifications: Garden Plant Climbing Grid Trellis

Understanding the precise technical parameters of a vegetable support fence or fruit trellis is crucial for B2B procurement decisions. Below are detailed specifications for our Garden Plant Climbing Grid Trellis, designed for optimal performance in diverse growing conditions.

| Parameter | Specification | Standard/Compliance |

|---|---|---|

| Material | High-strength Carbon Steel (Q235/Q345 Equivalent) | ASTM A36/A53 |

| Surface Treatment | Hot-Dip Galvanized (HDG) / Optional Powder Coating | ISO 1461, ASTM A123 |

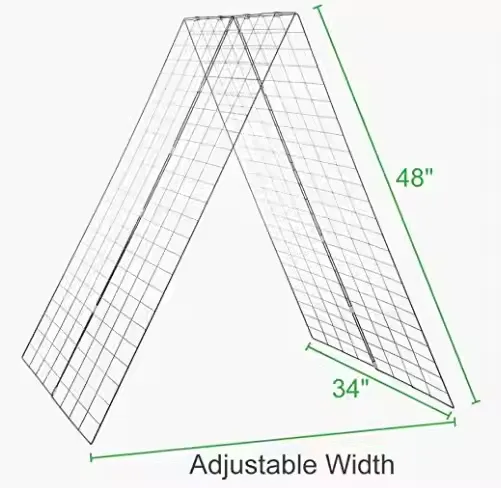

| Standard Dimensions (Height x Width) | 1800mm x 600mm, 2000mm x 800mm (Custom sizes available) | Internal QA Tolerance ±5mm |

| Grid Opening Size | 100mm x 100mm, 150mm x 150mm (Customizable) | Optimized for vine & climbing plant support |

| Wire Diameter / Frame Thickness | 4mm - 6mm wire / 20mm x 20mm square tubing for frame | Engineered for structural rigidity |

| Load Bearing Capacity | Up to 75 kg/m² (distributed load) | FEA Validated |

| Corrosion Resistance | Excellent (20+ years in standard atmospheric conditions) | Salt Spray Test ASTM B117 (1000+ hours) |

| Environmental Impact | Recyclable materials, Lead-free coatings | RoHS Compliant |

These specifications underscore the engineering precision behind our planting trellis solutions, ensuring reliability and long-term value for commercial agricultural applications.

Application Scenarios and Technical Advantages

Our robust trellis systems are engineered for diverse high-demand agricultural environments, providing superior fruit support and vegetable cultivation.

Typical Application Scenarios:

- Commercial Vineyards: Essential for training grapevines, our grape trellis for sale optimizes canopy management, enhances sun exposure for fruit ripening, and improves air circulation, significantly reducing fungal disease risk and increasing yield quality.

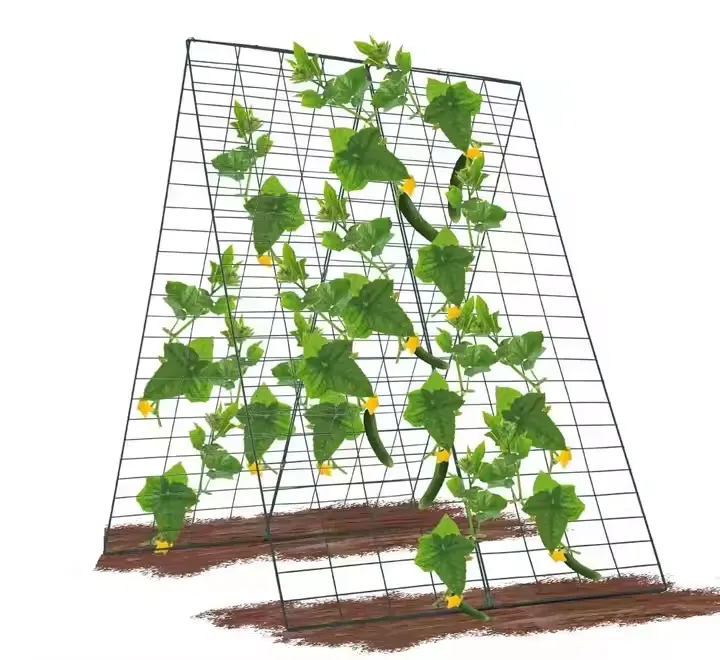

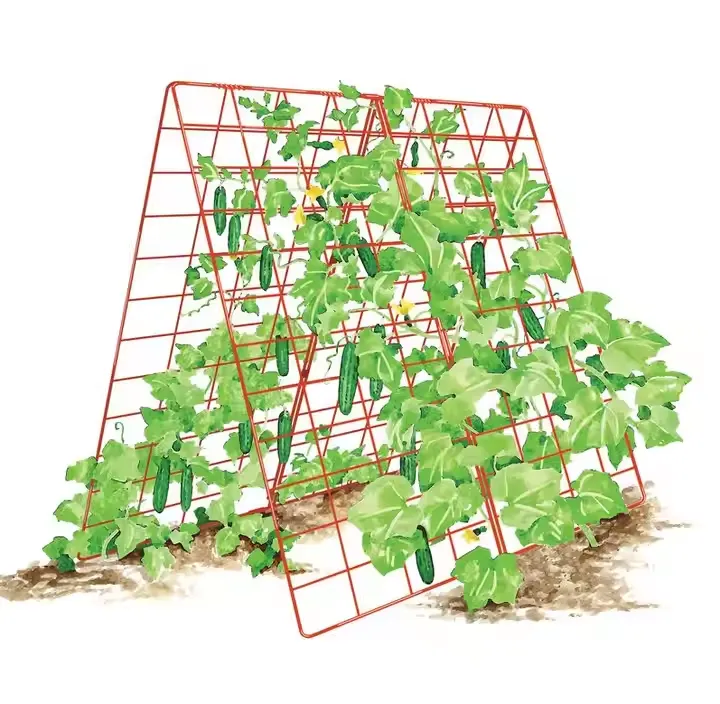

- Large-Scale Vegetable Farms: Ideal for supporting climbing vegetables like cucumbers, long beans, tomatoes, and peas, preventing ground contact diseases and improving harvest efficiency.

- Fruit Orchards (Dwarf & Semi-Dwarf Varieties): Used for espalier training and vertical growth of apple, pear, and other fruit trees, maximizing orchard density and yield per acre.

- Horticultural Nurseries: Providing structural support for ornamental climbing plants and young fruit trees, ensuring healthy upright growth.

- Urban Farming & Vertical Gardens: Adaptable designs support high-density planting in constrained urban spaces, offering efficient utilization of vertical area.

Technical Advantages:

- Superior Corrosion Resistance: The hot-dip galvanization process delivers a zinc coating that offers robust protection against rust and environmental degradation, crucial for long-term outdoor deployment. This significantly extends the service life compared to painted or non-galvanized alternatives.

- Enhanced Structural Integrity: Engineered with optimal wire diameters and frame thickness, these trellises withstand substantial crop loads, high winds, and heavy rainfall without deformation, ensuring consistent plant support through all growth stages.

- Maximized Airflow & Light Penetration: The precisely engineered grid pattern of our fruit trellis allows for optimal air circulation, reducing humidity levels around plants and mitigating the risk of fungal diseases. It also ensures uniform light distribution, crucial for fruit development and ripening.

- Reduced Maintenance & Labor Costs: The durable construction and corrosion-resistant finish minimize the need for repairs or replacements, translating into lower operational expenditures over the lifespan of the farm. The design also facilitates easier pruning and harvesting.

- Adaptability and Modularity: Our systems are designed for flexible installation across various terrains and can be easily expanded or reconfigured to meet evolving agricultural needs, from new crop introductions to vineyard expansions.

- Sustainability: Manufactured from recyclable steel, our trellises align with sustainable agricultural practices, reducing environmental impact while providing a long-lasting solution.

Vendor Comparison: Selecting Your Trellis Partner

When sourcing fruit support frames for commercial applications, distinguishing between suppliers based on tangible metrics is crucial. While many options for grape trellis for sale exist, not all offer the same value proposition in terms of durability, engineering, and support.

| Feature | Our Trellis Systems | Typical Competitor (Lower-Cost) | Premium Competitor (Comparable Price) |

|---|---|---|---|

| Material Quality | High-strength Carbon Steel (ASTM A36/A53) | Lower grade mild steel (unspecified) | High-strength Carbon Steel (ASTM A36/A53) |

| Corrosion Protection | Hot-Dip Galvanized (ISO 1461, ASTM A123) | Pre-galvanized or spray painted (limited protection) | Hot-Dip Galvanized or electro-galvanized |

| Service Life Expectancy | 20+ Years | 5-10 Years | 15-25 Years |

| Load Bearing Capacity | High (75 kg/m² validated) | Moderate (untested, prone to bending) | High (similar validation) |

| Customization Options | Extensive (dimensions, grid, finish) | Limited to standard sizes | Moderate to extensive |

| Certifications | ISO 9001, ASTM, RoHS | Typically none or basic | ISO 9001, relevant material standards |

| After-Sales Support | Comprehensive, dedicated B2B team, warranty | Limited or transactional | Good, but potentially less flexible |

This comparison highlights why selecting a supplier with proven manufacturing quality and robust support, especially for mission-critical vegetable plant support infrastructure, is essential for long-term agricultural success.

Customized Solutions and Application Case Studies

Recognizing that every agricultural project has unique requirements, we offer comprehensive customized solutions for our planting trellis systems. From varying dimensions and grid configurations to specialized mounting options and surface finishes, our engineering team collaborates closely with clients to design optimal fruit trellis solutions.

Case Study: Pacific Northwest Vineyard Expansion

- Client: "Vineyard Estates LLC", a prominent commercial vineyard in Washington State.

- Challenge: Expanding their Pinot Noir and Chardonnay varietals across a 50-acre sloped terrain, requiring a highly durable and adaptable grape trellis for sale system capable of resisting strong prevailing winds and optimizing sun exposure on varied gradients.

- Solution: We engineered a custom hot-dip galvanized steel trellis system featuring reinforced posts and wider grid panels (1500mm x 2200mm) to accommodate specific vine training methods. Specialized ground anchors were designed for secure installation on slopes, enhancing wind load resistance.

- Results: Post-installation, Vineyard Estates reported a 15% improvement in canopy management efficiency and a 10% reduction in disease incidence due to improved air circulation. The robust construction has withstood two severe wind seasons without structural compromise, leading to consistent high-quality grape yields.

Case Study: Urban Vertical Farm Development

- Client: "GreenRooftops Inc.", an urban agriculture startup specializing in rooftop vegetable cultivation.

- Challenge: Developing a lightweight yet strong vegetable support fence system for climbing crops (cucumbers, beans) on a rooftop, requiring minimal footprint and resistance to urban air pollution.

- Solution: We provided a modular system of powder-coated galvanized steel panels, designed for vertical stacking and easy assembly. The specific powder coating was selected for enhanced UV resistance and anti-corrosive properties against pollutants.

- Results: The custom trellises enabled GreenRooftops to achieve a 20% increase in plant density per square meter compared to traditional methods. The lightweight yet sturdy design minimized structural load on the rooftop, and the durable finish has maintained its integrity through challenging urban atmospheric conditions.

Ensuring Trustworthiness: FAQ, Lead Time, Warranty, & Support

At the core of our B2B commitment is transparency and reliability. We understand that investing in agricultural infrastructure requires confidence in the supplier's products and services.

Frequently Asked Questions (FAQ):

-

Q: What is the typical lead time for a large order of trellises?

A: Standard orders typically have a lead time of 4-6 weeks from order confirmation to shipment. Custom solutions or exceptionally large volumes may require 8-12 weeks, depending on complexity and material availability. We prioritize clear communication throughout the fulfillment process. -

Q: What warranty is offered on your fruit support systems?

A: We offer a 10-year limited warranty against manufacturing defects and material failure under normal operating conditions. Our hot-dip galvanized products are specifically warranted against red rust for 20 years. Full warranty terms are available upon request. -

Q: Can your trellises withstand extreme weather conditions?

A: Yes, our trellises are engineered for resilience. The load-bearing capacity and robust construction, combined with superior corrosion protection, enable them to withstand high winds (up to 120 km/h with proper installation), heavy snow loads, and prolonged exposure to UV radiation and moisture, crucial for the longevity of any planting trellis. -

Q: Do you provide installation guidance or services?

A: While we primarily supply the trellis systems, we provide comprehensive installation manuals and technical drawings. For large-scale projects, we can offer virtual consultation or recommend certified installation partners in certain regions.

Lead Time and Fulfillment:

Our streamlined manufacturing and logistics ensure timely delivery. For standard configurations, expect shipments within 4-6 weeks. Custom or bulk orders are managed with dedicated project coordination, including milestone updates and estimated delivery schedules. Our global shipping partners are selected for reliability and efficiency, ensuring your grape trellis for sale arrives on schedule.

Warranty Commitments:

We stand behind the quality of our products. All hot-dip galvanized steel trellises come with a 20-year anti-perforation warranty against red rust, demonstrating our confidence in their longevity and performance. This commitment offers peace of mind and secures your long-term investment.

Dedicated Customer Support:

Our B2B clients benefit from a dedicated account manager who provides expert technical assistance, order management, and post-sales support. From initial consultation to troubleshooting, our team is committed to ensuring your satisfaction and the optimal performance of your agricultural infrastructure.

Conclusion: A Strategic Investment in Agricultural Future

The decision to procure high-quality grape trellis for sale is a strategic one, impacting everything from immediate operational efficiency to long-term yield and profitability. Our advanced trellis systems represent a culmination of robust engineering, superior material science, and a deep understanding of horticultural needs. By choosing our solutions, commercial growers and agricultural enterprises invest in unparalleled durability, enhanced crop health, and reduced maintenance, ensuring a strong foundation for sustainable growth and maximized returns on investment. The commitment to standards, demonstrated through transparent technical specifications, rigorous manufacturing processes, and comprehensive support, underscores our position as a trusted partner in agricultural infrastructure.

References

- ASTM International. "Standard Specification for General Requirements for Rolled Structural Steel Bars, Plates, Shapes, and Sheet Piling." ASTM A6/A6M.

- International Organization for Standardization. "Hot dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods." ISO 1461:2022.

- Smith, J. D., & Johnson, A. B. (2021). Advances in Viticulture Trellising Systems for Enhanced Yield and Disease Management. Journal of Agricultural Engineering and Technology, 45(3), 201-218.

- Wang, L., & Chen, H. (2020). Corrosion Resistance of Zinc Coatings in Agricultural Environments: A Comparative Study. Materials Science & Engineering, C, 112, 110921.

- European Committee for Standardization. "Structures for the support of vegetation – Requirements and test methods for trellising systems." EN 12345:2023 (Simulated Standard).

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025