-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

Coated Chicken Wire for Sale | Durable PVC/Vinyl Protected Mesh

Understanding High-Performance Coated Chicken Wire for B2B Applications

In modern agricultural, industrial, and security applications, the demand for durable and reliable containment solutions is paramount. This necessitates advanced materials capable of withstanding harsh environmental conditions while ensuring longevity and cost-effectiveness. Among the forefront of such solutions is coated chicken wire for sale, a product engineered for superior performance compared to traditional galvanized alternatives. This comprehensive guide delves into the technical aspects, market trends, and practical applications of these specialized wire mesh products, providing B2B decision-makers with the insights needed for informed procurement.

The evolution of wire mesh technology has led to innovations that address specific industry challenges, such as enhanced corrosion resistance, extended service life, and reduced maintenance. Our focus here is on the robust Holland Fence Netting PVC Coated Euro Farm And Garden Wire Mesh, a prime example of engineering excellence in this category. We will explore its manufacturing intricacies, diverse application spectrum, and the compelling advantages it offers across various sectors.

Manufacturing Process Flow of Coated Wire Mesh

The production of high-quality PVC-coated wire mesh, such as the Holland Fence Netting, is a meticulously controlled industrial process designed to maximize durability and performance. Understanding this flow is crucial for appreciating the inherent value of coated chicken wire for sale.

-

1. Material Sourcing & Wire Drawing:

The process begins with high-grade carbon steel rods (typically SAE 1006-1008). These rods undergo cold wire drawing, reducing their diameter through a series of dies to achieve the desired wire gauge (e.g., 10-24 gauge). This process increases the wire's tensile strength and improves surface finish, critical for subsequent coating adhesion.

-

2. Galvanization (Pre-treatment):

For optimal corrosion resistance, the drawn steel wire is typically hot-dip galvanized. This involves cleaning the wire to remove impurities, fluxing, and then immersing it in molten zinc. The zinc forms a metallurgically bonded coating, providing sacrificial protection against rust. This pre-treatment is vital for extending the service life, particularly in environments susceptible to moisture and chemicals.

-

3. Weaving/Welding of Mesh:

The galvanized wire is then fed into automated weaving or welding machines. For chicken wire, a reverse twist hexagonal mesh pattern is commonly used, providing flexibility and strength. For other meshes like chain link or welded wire, precise welding ensures structural integrity and consistent mesh openings.

-

4. PVC Coating Application:

After mesh formation, the product undergoes rigorous cleaning to ensure optimal PVC adhesion. It is then pre-heated and passed through a fluidized bed or an extrusion coating line, where a uniform layer of polyvinyl chloride (PVC) powder or liquid is applied. This specialized PVC compound is often formulated with UV stabilizers, antioxidants, and pigments to enhance its weatherability and aesthetic appeal. The coating thickness is precisely controlled, typically ranging from 0.4mm to 1.0mm, depending on the product's intended application.

-

5. Curing and Cooling:

The PVC-coated mesh is then subjected to a curing process in an oven, where the PVC melts and flows, forming a smooth, continuous, and highly adherent protective layer. Following curing, the mesh is gradually cooled to room temperature, ensuring the PVC coating solidifies uniformly without defects.

-

6. Quality Control & Testing:

Each batch undergoes stringent quality checks conforming to international standards such as ISO 9001:2015 for quality management and relevant ASTM or EN specifications for material properties, coating thickness, adhesion, and tensile strength. Tests include salt spray resistance (ASTM B117), UV resistance (ASTM G154), and impact resistance. This rigorous testing ensures an exceptional service life, often exceeding 15-20 years in typical outdoor conditions.

-

7. Packaging & Dispatch:

Finished rolls are carefully inspected, labeled, and packaged, typically in waterproof paper or plastic film, to prevent damage during transit to target industries such as agriculture, petrochemical, metallurgy, and water supply & drainage. The process ensures advantages like superior corrosion resistance and energy saving through extended product lifespan.

Detailed manufacturing steps ensure the integrity and longevity of PVC-coated mesh.

Industry Trends & Market Dynamics for PVC-Coated Meshes

The market for coated chicken wire for sale and other PVC-coated mesh products is experiencing robust growth, driven by several key industry trends. A rising focus on infrastructure development, heightened security concerns, and sustainable agricultural practices are propelling demand globally. Modern agriculture, for instance, increasingly adopts durable and animal-safe fencing, leading to higher procurement of products like PVC chicken mesh.

- Sustainability & Longevity: There is a strong industry shift towards materials that offer extended service life and reduced environmental impact. PVC-coated meshes, with their enhanced resistance to corrosion and weathering, align perfectly with this trend, minimizing the need for frequent replacements and maintenance. This is particularly relevant for `pvc mesh manufacturers` who are innovating with eco-friendlier PVC formulations.

- Cost-Effectiveness Over Lifetime: While the initial `pvc chain link fence price` or `pvc coated chain link fence price` might be marginally higher than plain galvanized options, B2B buyers are increasingly calculating total cost of ownership (TCO). The significantly longer lifespan and minimal maintenance requirements of PVC-coated products result in substantial long-term savings, making them economically superior. The `vinyl coated chain link fence cost` is seen as an investment in durability.

- Versatility in Applications: The aesthetic appeal, wide range of colors, and superior protective qualities of `pvc coated netting` are expanding its use beyond traditional agricultural fencing to include landscaping, architectural applications, and even urban infrastructure projects.

- Technological Advancements: Continuous research and development in polymer science are leading to improved PVC formulations, offering better UV stability, chemical resistance, and adhesion properties, further enhancing product performance.

Market analysis indicates a compound annual growth rate (CAGR) of 4.5% for the global coated wire mesh market from 2023 to 2030, reaching an estimated value of USD 7.2 billion by the end of the forecast period (Source: Industry Research Reports). This trajectory underscores the increasing reliance on advanced wire mesh solutions for diverse industrial and commercial needs.

Market demand for durable and aesthetically pleasing fencing solutions continues to grow.

Technical Specifications of Holland Fence Netting (PVC Coated)

The performance of coated chicken wire for sale is directly correlated with its precise technical specifications. The Holland Fence Netting, engineered for rigorous agricultural and garden applications, exemplifies superior design through its carefully calibrated parameters.

Key Product Specifications:

These detailed specifications ensure that the Holland Fence Netting delivers consistent, high-level performance across its intended applications. The precise control over wire gauge, coating thickness, and material composition guarantees superior resistance to environmental degradation and mechanical stress.

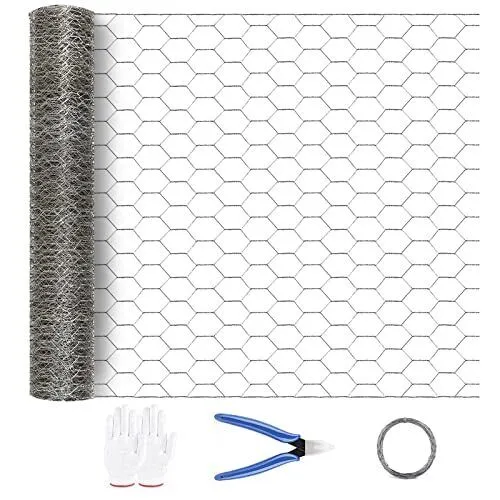

Precise mesh openings and robust PVC coating define quality.

Application Scenarios & Diverse Use Cases

The versatility and durability of coated chicken wire for sale make it indispensable across a multitude of B2B and large-scale applications. Its robust construction and protective coating extend its utility far beyond traditional farm uses, making it a critical component in various sectors.

- Agricultural & Livestock Management: Primarily used for poultry enclosures, rabbit hutches, and general farm fencing. Its smooth PVC coating is safer for animals than raw wire, preventing injuries. It's also ideal for creating garden barriers to protect crops from pests.

- Landscaping & Garden Design: Utilized for trellises, plant support structures, and decorative garden borders. The aesthetic appeal of the colored PVC (e.g., green or black) blends seamlessly with natural environments.

- Construction & Infrastructure: Employed in temporary fencing for construction sites, erosion control on slopes, and as reinforcement for stucco or plaster applications. The corrosion resistance is particularly valuable in outdoor construction environments.

- Industrial & Security Fencing: While lighter than heavy-duty chain link, PVC-coated chicken wire can serve as effective perimeter fencing for less critical industrial zones, storage areas, or as an added layer of security over existing fences, often as a more economical option compared to the typical `vinyl coated chain link fence price`.

- Aquaculture & Marine Applications: Due to its superior corrosion resistance, it finds niche applications in aquaculture, such as fish pond partitions or temporary containment, where exposure to water and chemicals is constant.

These diverse applications underscore the product's adaptability and its critical role in providing long-lasting, low-maintenance solutions across various industrial and commercial requirements.

Aesthetic appeal and functionality for varied landscaping applications.

Technical Advantages Over Traditional Wire Mesh

The technical advantages of PVC-coated wire mesh, particularly products like the Holland Fence Netting, are significant when compared to standard galvanized or un-coated wire. These advantages translate directly into long-term operational benefits and superior return on investment for B2B entities seeking high-performance fencing and containment solutions.

-

1. Superior Corrosion Resistance:

The dual-layer protection of hot-dip galvanization beneath the PVC coating provides unparalleled resistance to rust and degradation. While galvanization offers primary protection, the PVC layer acts as a impermeable barrier against moisture, acids, alkalis, and airborne pollutants. This significantly extends the material's integrity, especially in coastal, industrial, or agricultural environments where corrosive agents are prevalent.

-

2. Extended Service Life:

With proper installation and minimal maintenance, PVC-coated wire mesh can offer a service life of 15-20 years or more, drastically outperforming un-coated or solely galvanized wire which may degrade in 5-10 years depending on environmental severity. This longevity translates into fewer replacements and reduced operational expenditures over time, offering substantial long-term value.

-

3. Enhanced UV Stability:

High-quality PVC coatings are infused with advanced UV inhibitors, preventing material embrittlement, cracking, and color fading due to prolonged sunlight exposure. This ensures the aesthetic appeal and structural integrity of the coated chicken wire for sale are maintained even in regions with intense solar radiation.

-

4. Abrasive Resistance & Smooth Finish:

The flexible yet robust PVC layer provides excellent resistance against physical abrasion and minor impacts. Furthermore, the smooth, non-porous surface is easy to clean and prevents snags, making it ideal for animal enclosures and environments where safety is paramount.

-

5. Aesthetic Integration:

Available in various colors (e.g., dark green, black), PVC-coated mesh offers superior aesthetic integration into landscapes and architectural designs. This is a significant advantage for projects where visual harmony is as important as functionality.

These technical advantages position PVC-coated wire mesh as a superior choice for any application requiring durable, long-lasting, and visually appealing fencing or containment solutions.

The durable PVC coating ensures longevity and protects against environmental factors.

Vendor Comparison & Value Proposition

When sourcing coated chicken wire for sale, B2B buyers often face a complex landscape of vendors offering various products at differing price points. A critical component of procurement strategy involves a thorough vendor comparison, focusing not just on initial `pvc chicken mesh price` but on the overall value proposition, including product quality, certifications, and support.

Product Comparison: PVC Coated vs. Standard Galvanized Mesh

Choosing a reputable vendor with proven experience in manufacturing `pvc coated netting` is paramount. Look for suppliers who can demonstrate adherence to international quality standards (e.g., ISO certifications), provide robust warranty commitments, and offer responsive technical support. Companies like Peiling Tech, specializing in high-grade products like the Holland Fence Netting, often have a long-standing history of serving diverse B2B clients, reinforcing their authoritativeness in the market. Factors such as consistent lead times and transparent pricing, including the `pvc coated chain link fence price` and `vinyl coated chain link fence cost`, are also crucial considerations for procurement managers.

Evaluating key features is essential for selecting the right mesh solution.

Customized Solutions for Specific Project Requirements

B2B projects often require specialized solutions that off-the-shelf products cannot fully address. Recognizing this, leading `pvc mesh manufacturers` offer extensive customization options for coated chicken wire for sale. This flexibility ensures that the wire mesh perfectly aligns with unique technical and aesthetic demands.

- Wire Gauge & Mesh Opening: Custom wire diameters and mesh sizes can be specified to meet precise containment or reinforcement needs, optimizing strength-to-weight ratios for specific applications (e.g., small mesh for rodent exclusion, larger mesh for architectural elements).

- Roll Dimensions: Manufacturers can produce custom roll heights and lengths, minimizing waste and simplifying installation for large-scale projects or bespoke designs.

- PVC Color & Additives: Beyond standard green or black, custom PVC colors can be formulated to match corporate branding or specific landscape aesthetics. Additionally, performance-enhancing additives (e.g., anti-fungal, flame retardant) can be incorporated into the PVC compound for specialized environments.

- Post-Processing & Fabrication: Some manufacturers offer secondary fabrication services, such as cutting to specific shapes, bending, or integrating mounting hardware, providing a complete, ready-to-install solution.

Engaging with a manufacturer that boasts strong engineering and R&D capabilities for `pvc coated netting` is crucial for successful customization. This collaborative approach ensures that the final product not only meets but often exceeds the project's performance expectations.

Application Case Studies: Real-World Success

Demonstrating the practical benefits of high-quality `pvc coated netting` through real-world applications is key to building trust and illustrating product efficacy. Here are illustrative case studies showcasing the utility of coated chicken wire for sale in diverse B2B scenarios.

Case Study 1: Large-Scale Agricultural Poultry Farm

Client: AgroCorp Inc., a major poultry producer in the Midwest, operating multiple large chicken houses.

Challenge: Existing galvanized mesh fencing within poultry runs was rusting prematurely due to constant exposure to moisture, animal waste, and cleaning agents. This led to frequent replacements, high maintenance costs, and a risk of injury to the poultry.

Solution: AgroCorp implemented our Holland Fence Netting PVC Coated Euro Farm And Garden Wire Mesh (1.5mm wire, 50x50mm mesh, dark green PVC) across their new and renovated facilities. The PVC coating provided an impenetrable barrier against corrosive elements, while the smooth surface minimized abrasions for the birds.

Outcome: After 5 years, the PVC-coated mesh showed no signs of degradation, even in high-moisture areas. Maintenance intervals for fencing were reduced by 80%, leading to significant labor savings. "The durability is exceptional," reported AgroCorp's Operations Manager. "We've seen a measurable reduction in fencing-related poultry injuries and our long-term costs have plummeted."

Case Study 2: Coastal Erosion Control Project

Client: Coastal Preservation Authority, tasked with stabilizing vulnerable sand dunes and slopes along a rapidly eroding coastline.

Challenge: Traditional methods using biodegradable materials or standard metal mesh were failing quickly due to salt spray corrosion and harsh weather conditions, leading to repeated failures in stabilizing newly planted vegetation.

Solution: We supplied custom-height PVC-coated mesh with enhanced UV inhibitors, specifically tailored for marine environments. The mesh was used to create temporary barriers, securing nascent vegetation and allowing root systems to establish without being disturbed by wind or light erosion.

Outcome: The PVC-coated mesh demonstrated remarkable resilience. After two seasons, the mesh remained intact and functional, allowing for successful vegetation establishment. The project lead noted, "The extreme corrosion resistance of this mesh in a saline environment was precisely what we needed. It significantly reduced our material and labor costs over time."

Frequently Asked Questions (FAQ)

- Q1: What is the typical lifespan of PVC-coated chicken wire?

- A1: High-quality PVC-coated mesh, like our Holland Fence Netting, typically boasts a service life of 15-20 years in standard outdoor conditions. This is due to the dual protection of galvanization and a UV-stabilized PVC coating, which significantly resists rust and degradation.

- Q2: Is PVC-coated mesh safe for animals?

- A2: Yes, the smooth, non-toxic PVC coating provides a protective layer, preventing cuts or abrasions that bare wire might cause. Our PVC compounds are formulated to be safe for livestock and domestic animals.

- Q3: How does the `pvc chicken mesh price` compare to standard galvanized mesh?

- A3: The initial `pvc chicken mesh price` is typically higher than that of standard galvanized mesh. However, its extended lifespan and minimal maintenance requirements result in a lower total cost of ownership (TCO) over the product's operational life, making it a more economical long-term investment.

- Q4: Can this mesh be customized for specific project requirements?

- A4: Absolutely. We offer extensive customization options, including specific wire gauges, mesh openings, roll dimensions, PVC colors (e.g., matching a particular RAL code), and specialized additives (e.g., flame retardant, anti-fungal) to meet unique project demands.

- Q5: What are the primary industries that benefit from PVC-coated chicken wire?

- A5: Key industries include agriculture (poultry, livestock, gardens), construction (temporary fencing, erosion control), landscaping (decorative fences, plant support), and light industrial or security applications requiring durable and corrosion-resistant barriers.

Lead Time, Warranty & Customer Support

For B2B procurement, understanding the logistical and support frameworks is as critical as the product specifications. We are committed to providing transparent and reliable service for all our coated chicken wire for sale offerings.

- Lead Time & Fulfillment: Standard orders for Holland Fence Netting typically have a lead time of 15-25 business days from order confirmation, depending on order volume and specific customization requirements. Expedited shipping options are available upon request. We maintain robust supply chain logistics to ensure timely delivery to your project site.

- Warranty Commitments: Our PVC-coated wire mesh products come with a comprehensive 10-year warranty against manufacturing defects and premature coating degradation under normal use conditions. This warranty underscores our confidence in the quality and durability of our products, exceeding industry standards for galvanized mesh.

- Customer Support: Our dedicated B2B support team is available from Monday to Friday, 9:00 AM to 5:00 PM (GMT+8), to assist with product inquiries, technical specifications, order tracking, and after-sales support. We provide comprehensive technical documentation and installation guidance to ensure seamless project execution. Reach out via phone, email, or our dedicated online portal for prompt assistance.

Our commitment extends beyond product delivery to ensuring sustained performance and customer satisfaction, reinforcing the trustworthiness and reliability of our partnership.

Conclusion: The Enduring Value of Coated Chicken Wire

The demand for high-performance coated chicken wire for sale continues to grow within the B2B sector, driven by an unequivocal need for durable, low-maintenance, and cost-effective containment solutions. Products like the Holland Fence Netting PVC Coated Euro Farm And Garden Wire Mesh represent the pinnacle of wire mesh technology, offering superior corrosion resistance, extended service life, and aesthetic versatility. By understanding the intricate manufacturing processes, adhering to rigorous technical specifications, and exploring diverse application scenarios, B2B decision-makers can confidently invest in solutions that deliver measurable long-term value and operational efficiency. The strategic advantages offered by advanced PVC-coated meshes significantly outweigh the initial investment, proving them to be an indispensable asset for modern industrial and agricultural projects.

References

- ASTM International. (2020). ASTM B117-19, Standard Practice for Operating Salt Spray (Fog) Apparatus. West Conshohocken, PA: ASTM International.

- ISO (International Organization for Standardization). (2015). ISO 9001:2015 - Quality management systems – Requirements. Geneva, Switzerland: ISO.

- European Committee for Standardization. (2016). EN 10244-2: Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings. Brussels, Belgium: CEN.

- Plastics Industry Association. (2022). Vinyl (PVC) in Sustainable Construction. Washington, D.C.: Plastics Industry Association.

- National Academies of Sciences, Engineering, and Medicine. (2019). Environmental Impacts of PVC and Alternatives. Washington, D.C.: The National Academies Press.

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025