-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

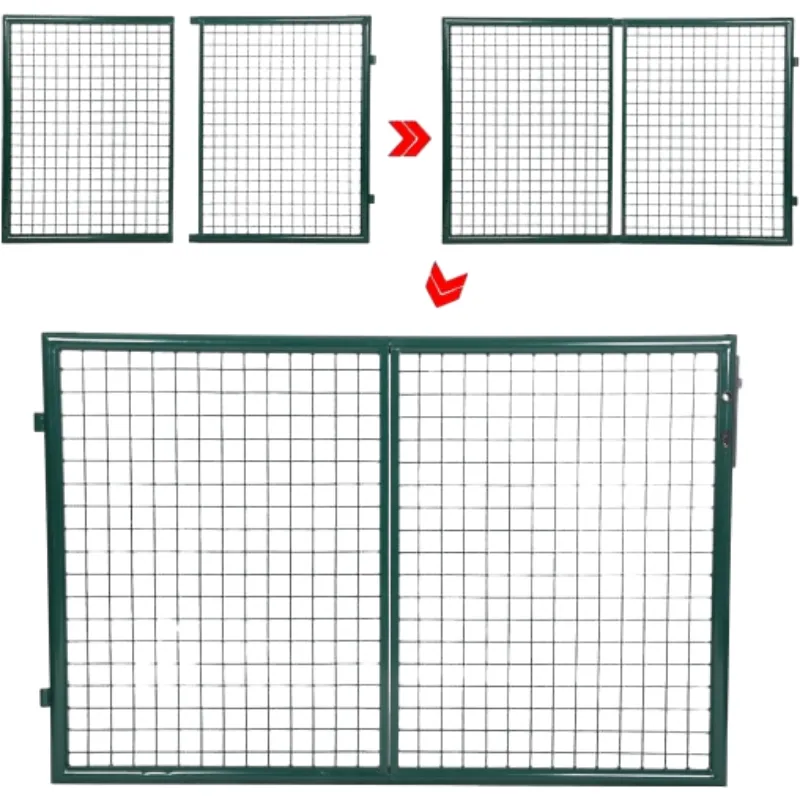

Double Wing Mesh Metal Door with Round Pipe Splice Plate

Unveiling the Innovation: Understanding the Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door

In the evolving landscape of industrial and architectural infrastructure, specialized components play a pivotal role in ensuring both functionality and security. Among these, the Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door stands out as a uniquely engineered solution designed for critical access points. This comprehensive guide delves into its structure, applications, and the technological advancements that make it indispensable across diverse sectors, ensuring a blend of robust security, ventilation, and structural integrity for specific installations.

Industry Trends and the Demand for Specialized Access Solutions

The global industrial and commercial construction sectors are witnessing a pronounced shift towards highly specialized and integrated building components. Factors such as enhanced security requirements, optimized airflow and ventilation needs, and the integration of complex piping and cabling systems are driving this demand. Specifically, industries dealing with sensitive equipment, hazardous materials, or controlled environments require entrance solutions that go beyond conventional doors. They need products that can seamlessly integrate with existing infrastructure, such as round pipe frameworks, while offering superior durability and compliance with stringent safety standards.

Data from Mordor Intelligence indicates that the global industrial doors market, part of which this specialized product falls, is projected to grow significantly, driven by increasing industrialization and infrastructure development. The report forecasts a Compound Annual Growth Rate (CAGR) of approximately 4.5% from 2023 to 2028, reaching an estimated market size of over $20 billion. The need for doors that facilitate efficient maintenance, provide robust security against unauthorized access, and yet allow for necessary air circulation (via mesh designs) is paramount. The Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door directly addresses these intricate requirements, positioning itself as a cutting-edge solution for modern industrial facilities requiring high performance and specific structural compatibility.

Technical Parameters and Specifications

The efficacy of any industrial component lies in its precise technical specifications. The Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door is engineered with meticulous attention to detail, ensuring optimal performance and longevity. Below is a generalized table of typical parameters that illustrate its robust design and adaptability. Specific dimensions and material grades can be customized based on project requirements and environmental conditions, ensuring optimal integration and longevity.

| Parameter | Typical Specification Range | Notes on Performance & Customization |

|---|---|---|

| Material (Frame & Door Body) | Carbon Steel (Q235, Q345, A36), Stainless Steel (304, 316, 316L, Duplex SS) | Choice depends on required strength, corrosion resistance (e.g., 316L for high chloride environments), and budget. High-strength alloys available. |

| Mesh Material & Configuration | Galvanized Steel, Stainless Steel (304, 316); Welded Wire Mesh, Expanded Metal Mesh | Mesh size (e.g., 12x12mm to 50x50mm) and wire thickness (e.g., 2mm to 5mm) can be specified for ventilation, visibility, and anti-intrusion needs. |

| Pipe Splice Plate Thickness | 6mm - 12mm (0.24" - 0.47") | Varies significantly with applicable pipe diameter (e.g., DN100 to DN500) and structural load requirements. Designed for secure, load-bearing connection. |

| Door Leaf Thickness | 40mm - 80mm (1.57" - 3.15") | Influences security rating, acoustic insulation, and thermal properties. Can incorporate internal stiffeners for enhanced rigidity. |

| Surface Treatment | Hot-dip Galvanizing (ASTM A123), Powder Coating (min. 60-80 microns thickness, wide RAL range), Electro-polishing (for SS), Primer + Top Coat Systems | Provides superior corrosion protection and aesthetic finish. Longevity of coating is critical for harsh industrial settings. |

| Opening Mechanism | Heavy-duty Hinged (left/right swing), Double Swing (bi-parting) | Optimized for high-cycle industrial use. Heavy-duty bearing hinges ensure smooth operation and durability under constant use. |

| Locking System Options | Industrial-grade multi-point locks, Panic bar hardware, Digital keypad locks, Compatibility with facility-wide access control (e.g., card readers, biometrics) | Ensures high-level security compliant with relevant security standards. Anti-pry features are standard. |

| Fire Rating (Optional) | Up to 1 to 2 Hours (e.g., UL 10B/C, NFPA 252, EN 1634-1) | Specific models can be engineered and certified to meet fire safety and compartmentation requirements, using fire-resistant core materials and intumescent seals. |

| Overall Dimensions | Fully Customizable (e.g., single leaf W1000-1500mm x H2000-3000mm; double leaf W1500-3500mm x H2000-4500mm) | Precision fabricated to fit exact opening sizes, ensuring minimal on-site adjustments. |

| Design Life | Minimum 20-30 years with proper maintenance | Engineered for extreme durability and long-term performance in demanding industrial environments. |

Manufacturing Process of the Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door

The manufacturing of a Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door is a sophisticated process that combines precision engineering with skilled craftsmanship. It ensures the final product meets stringent performance and safety standards. The core methodologies typically involve a combination of cutting, forming, welding, and finishing techniques, all under strict quality control protocols.

Detailed Manufacturing Workflow:

Fig 1: Advanced manufacturing techniques, including precision CNC and meticulous welding, ensure the structural integrity and perfect fit of our industrial doors.

Application Scenarios and Technical Advantages

The versatility and robust design of the Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door make it ideal for a multitude of demanding industrial and commercial environments. Its unique construction provides distinct technical advantages over standard door systems, addressing specific challenges in high-stakes settings.

Key Application Scenarios:

- Petrochemical Plants and Refineries: Critical for securing access to areas with extensive pipe networks, allowing for controlled ventilation of volatile compounds, heat dissipation, and prevention of unauthorized entry. The anti-corrosion properties (especially with 316L SS or hot-dip galvanization) are vital here due to exposure to aggressive chemicals and harsh atmospheric conditions.

- Metallurgical and Heavy Manufacturing Facilities: Provides secure and robust access to furnace areas, rolling mills, casting zones, and equipment enclosures. The mesh design facilitates heat dissipation and visibility, while the heavy-duty construction withstands harsh operational environments, including dust, high temperatures, and mechanical stresses.

- Water Treatment and Wastewater Facilities: Ideal for pump houses, valve stations, chemical dosing areas, and access to pipe galleries where consistent ventilation is crucial to prevent gas accumulation (e.g., hydrogen sulfide) and control humidity, which reduces corrosion on internal equipment. Simultaneous restricted access is maintained.

- Power Generation Plants (Conventional & Renewable): Used in turbine halls, boiler areas, substations, and equipment enclosures for securing critical electrical and mechanical apparatus. Facilitates airflow for cooling, maintains security around crucial piping infrastructure, and allows visual inspection of key areas.

- Data Centers and Telecommunication Hubs: While traditionally employing solid doors for fire and climate control, specialized data centers requiring secure, ventilated enclosures for specific equipment racks or zones with integrated cooling pipe systems can utilize customized versions for airflow management and enhanced security.

- Pharmaceutical and Chemical Processing Plants: For controlled access to production zones, offering a blend of high-level security and visual inspection capabilities through the mesh, while seamlessly accommodating existing pipe structures within the facility's framework. Compliance with strict hygiene and safety standards is paramount.

- Infrastructure Tunnels and Galleries: Securing access points to underground utility tunnels containing essential pipes (water, gas), cables (electrical, data), and ventilation systems. These doors provide robust security against vandalism and unauthorized access, while allowing critical airflow for maintenance teams and environmental control.

- Logistics and Warehousing (High-Security Areas): For specific zones within large warehouses or distribution centers that house high-value goods or sensitive materials, where both security and ventilation/visibility are required and structural integration with existing pipe-based racking or support systems is necessary.

Technical Advantages:

- Seamless Structural Integration (Splice Plate Design): The core innovation lies in the specialized "splice plate" mechanism. This design allows for direct, secure, and robust mounting onto existing or new round pipe frames (columns, supports, fences). This eliminates the need for expensive, time-consuming custom framing or extensive on-site structural modifications, significantly reducing installation time and overall project costs.

- Enhanced Security and Robustness: Constructed from heavy-gauge industrial-grade metals and featuring advanced, multi-point locking mechanisms, these doors provide superior protection against forced entry, vandalism, and unauthorized access. The mesh design, while allowing visibility, acts as a formidable physical barrier against intrusion.

- Optimized Ventilation and Environmental Control: The integrated mesh design facilitates essential natural air circulation, which is crucial in environments where heat dissipation, gas dispersion (e.g., in pump stations or chemical storage), or humidity control is required. This passive ventilation can lead to significant energy savings by reducing reliance on active HVAC systems and can prevent the buildup of hazardous fumes.

- Superior Corrosion and Environmental Resistance: Available in high-grade stainless steel (304, 316L, duplex SS) or carbon steel with advanced hot-dip galvanizing (up to 80-100 microns zinc coating) or multi-layer powder coating, these doors are engineered to withstand extremely harsh corrosive environments, including chemical exposure, high humidity, and marine climates. This significantly extends their service life, reducing costly maintenance and premature replacement.

- Exceptional Durability and Longevity: Built to rigorous industrial standards with robust materials, precision CNC fabrication, and high-quality welding (e.g., according to ISO 3834 and AWS D1.1), these doors are designed for heavy-duty, continuous operation under demanding conditions. This leads to a significantly longer operational lifespan (often 20-30+ years) and a lower total cost of ownership (TCO) compared to standard commercial doors.

- Customization for Precise Operational Needs: Beyond standard dimensions, the doors can be tailored to incorporate specific requirements such as fire ratings (e.g., EN 1634-1 compliant), acoustic insulation, specialized mesh patterns for debris protection or high-security, integration with complex access control systems, and specific opening mechanisms (e.g., panic egress, automated opening). This ensures a perfect functional and structural fit for any unique application.

- Reduced Maintenance Requirements: Thanks to their robust construction and superior anti-corrosion treatments, these doors require minimal routine maintenance, typically limited to periodic inspection of hinges and locks, and occasional cleaning. This reduces operational overheads and ensures consistent reliability.

Manufacturer Comparison and Why Choose PeilingTech

When selecting a supplier for highly specialized industrial doors like the Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door, it's crucial to evaluate manufacturers based on their engineering expertise, quality control, customization capabilities, and post-sales support. While several manufacturers might offer seemingly similar products, the distinctions in engineering prowess, operational efficiency, and commitment to client success are significant.

| Feature | PeilingTech Advantage | Typical Competitor Approach | |||

|---|---|---|---|---|---|

| Engineering & Design Prowess | Deep specialization in complex industrial structures; advanced 3D CAD/CAM modeling; iterative design for optimal performance, particularly for the unique splice plate integration. Focus on problem-solving custom solutions. | More generic, off-the-shelf designs; limited capacity for bespoke engineering; may require more on-site modifications to fit specific pipe structures, leading to unforeseen costs and delays. | |||

| Material Sourcing & Quality Assurance | Rigorous incoming inspection (ISO 9001:2015 certified); traceable material batches with mill certificates; exclusive use of premium, certified steel grades (e.g., ASTM, AISI, EN standards). Partnership with reputable global suppliers. | Standard material grades; less stringent pre-production checks; potential for material inconsistencies or use of non-certified materials affecting long-term durability and safety. | |||

| Manufacturing Processes & Technology | State-of-the-art CNC machining, robotic welding for precision and consistency (conforming to ISO 3834); multi-stage, high-grade surface treatment facilities (e.g., automated hot-dip galvanizing lines per ASTM A123, advanced powder coating booths). Adherence to tight manufacturing tolerances. | Higher reliance on manual processes; less automated stages; potentially lower weld quality, inconsistent coating application, and looser dimensional tolerances, impacting fit and finish. | |||

| Customization Flexibility & Adaptability | Unparalleled customization: from precise dimensions, specific material grades, intricate mesh patterns, advanced locking mechanisms, to full integration with client's existing infrastructure and control systems. Rapid prototyping and design review cycles. | Limited standard options; high additional cost and longer lead times for minor deviations; less willingness to undertake complex custom orders or provide tailored engineering support. | |||

| Quality Control & Performance Testing | Multi-point QC throughout production, including NDT on welds, dimensional verification, coating thickness checks (e.g., using dry film thickness gauges), and comprehensive final functional testing. Adherence to international standards (e.g., ANSI, ISO, CE for relevant markets). Full documentation and traceability records. | Basic end-of-line checks only; may not conduct in-process quality control; less adherence to comprehensive international standards; limited test reports or traceability data. | |||

| Project Management & Technical Support | Dedicated project managers, expert technical consultation from concept and design to installation guidance, comprehensive after-sales support, readily available spare parts, and remote diagnostic assistance. Over a decade of industry experience. | Limited pre-sales consultation; minimal post-installation support; generic service approach; potentially longer response times for inquiries or issues. | Lead Time & Delivery Reliability | Optimized production lines and robust supply chain management lead to competitive and reliable delivery schedules, even for complex custom orders. Transparent communication on project milestones. | Variable and often extended lead times, especially for non-standard configurations, due to less efficient production planning and supply chain vulnerabilities. |

Choosing PeilingTech means partnering with a manufacturer that prioritizes precision, durability, and customer-specific solutions. Our commitment to meeting and exceeding industry standards ensures that every Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door delivers unparalleled performance, reliability, and security over its extensive lifespan, offering true long-term value and peace of mind.

Customization Solutions and Integration

Understanding that every industrial site has unique requirements, PeilingTech offers extensive customization options for the Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door. Our engineering team works closely with clients to design a solution that perfectly integrates with existing infrastructure and operational demands. Customization extends beyond mere dimensions to encompass a holistic approach to functionality, environmental compliance, and enhanced security.

- Tailored Dimensions and Configurations: We manufacture doors to precise measurements, whether it's an unusually wide entrance requiring an oversized double-wing door, a compact space necessitating specific swing directions, or an installation into a uniquely shaped opening. Our designs adapt to various pipe diameters (e.g., DN100 to DN500) for the splice plate integration.

- Material Upgrades and Specialized Coatings: For highly corrosive or extreme environments (e.g., coastal areas with high salinity, chemical processing plants with aggressive fumes, or areas with high UV exposure), we offer upgraded materials like Duplex Stainless Steel (e.g., 2205, 2507) for superior strength and corrosion resistance, or specialized protective coatings such as fluoropolymer coatings (e.g., PVDF, PTFE) for chemical inertness and enhanced durability.

- Advanced Security Features Integration: Customization includes the integration of state-of-the-art security hardware. This ranges from multi-point industrial locking systems, heavy-duty deadbolts, panic bars for emergency egress (compliant with NFPA 101), to seamless compatibility with facility-wide access control systems (e.g., RFID card readers, biometric scanners, intercom systems, CCTV integration). Tamper-proof hinge designs and reinforced frames are standard.

- Mesh Specification for Diverse Needs: Varying mesh sizes, patterns, and wire gauges can be incorporated to balance specific security needs with ventilation and visibility requirements. Options range from fine mesh for pest control or high-security anti-climb mesh to larger mesh for maximum airflow and visual monitoring. Materials can include galvanized steel, stainless steel, or even reinforced mesh for ballistic resistance in specialized applications.

- Environmental Controls and Performance Enhancements: We offer options for integrating high-performance weather stripping (e.g., EPDM, silicone) for improved sealing against dust, moisture, and temperature fluctuations. Acoustic insulation can be added for noise reduction. For critical applications, doors can be engineered to meet specific fire ratings (e.g., UL, EN standards) or pressure ratings for blast protection.

- Seamless Integration with Existing Pipe Systems: The core of our specialization lies in the "round pipe splice plate." Our engineering team meticulously designs these plates to fit various pipe diameters, wall thicknesses, and structural configurations, ensuring a perfectly secure and aesthetically integrated fit without compromising the structural integrity of the existing pipe framework or the door itself. This bespoke fit is often achieved through precise laser scanning of existing structures for unmatched accuracy.

- Automation and Monitoring: For high-traffic or remotely managed access points, we can integrate automated opening/closing mechanisms (e.g., hydraulic, pneumatic, electric operators) and real-time door status monitoring (open/closed, locked/unlocked) for enhanced operational efficiency and security oversight.

Our collaborative design process ensures that every Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door is not just a product, but a tailor-made solution engineered for peak performance and seamless integration into your unique operational environment.

Illustrative Application Cases and Client Successes

The practical application of the Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door across various industries underscores its versatility, effectiveness, and the tangible benefits it brings. These generalized examples highlight its real-world impact and our commitment to delivering superior solutions.

Fig 2: A secure industrial access point featuring the double-wing mesh metal door, integrated seamlessly with the facility's existing round pipe support structure.

- Case Study 1: Major Refinery Expansion (Petrochemical Industry)

Challenge: A leading petrochemical company embarked on a multi-billion-dollar expansion project, requiring enhanced security and ventilation in critical process units where extensive piping manifolds and structural pipe columns were pervasive. Standard industrial doors proved difficult to integrate without extensive and costly structural modifications. The environment demanded high corrosion resistance against sulfur compounds and saline air.

Solution: PeilingTech was contracted to supply over 50 custom-fabricated Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door units. These were meticulously engineered from 316L stainless steel for maximum corrosion resistance and featured a precise splice plate design that allowed for direct, secure, and rapid mounting onto existing DN200 (8-inch) schedule 40 pipe supports. The double-wing configuration ensured ample clearance for maintenance equipment. The integrated mesh design provided essential airflow, mitigating gas accumulation risks within enclosed areas, while robust, industrial-grade locking systems ensured high-level security.

Outcome: The client reported a significant reduction in installation time (estimated 30% faster than conventional methods) and associated labor costs. The superior corrosion resistance minimized long-term maintenance needs. Most importantly, the doors contributed significantly to improved operational safety and security within the high-risk zones, receiving commendation for their seamless integration and robust performance. - Case Study 2: Municipal Water Treatment Plant Upgrade (Water & Wastewater Management)

Challenge: A large urban water treatment facility needed to upgrade the security for its critical pump stations, chemical dosing areas, and underground pipe galleries. Existing structures were supported by weathered round steel columns (DN250, 10-inch) that needed robust door integration. The humid, chemically active environment posed a significant corrosion risk, and consistent ventilation was necessary to prevent the buildup of hazardous gases.

Solution: PeilingTech designed and manufactured custom Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door systems. These doors were fabricated from hot-dip galvanized carbon steel (per ASTM A123, providing a zinc coating of minimum 85 microns) for long-term corrosion protection in the humid, intermittently chemical-exposed environment. The splice plates were precisely designed to encapsulate the existing pipe columns, ensuring a solid, unyielding frame. The double-wing configuration facilitated the frequent movement of large pumps and filtration equipment, significantly enhancing operational efficiency during maintenance cycles. The mesh allowed for crucial passive ventilation.

Outcome: The project was completed ahead of schedule due to the ease of installation. The client lauded the doors' exceptional build quality and the effective solution to their dual needs for robust security and critical ventilation. The long-term corrosion resistance has led to a projected 50% reduction in door maintenance costs over a 10-year period compared to previous installations. - Case Study 3: Electrical Substation Perimeter Security (Energy Sector)

Challenge: A high-voltage electrical substation required enhanced perimeter security around its critical transformer and switchgear areas. The existing perimeter was defined by a series of robust round steel posts that also supported overhead cabling. A solution was needed that would deter trespassers and prevent unauthorized access while allowing for necessary air circulation around equipment and quick, secure access for authorized personnel.

Solution: PeilingTech supplied multiple Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door units, specifically designed to integrate seamlessly with the DN150 (6-inch) fence line posts. The doors featured heavy-duty anti-cut mesh (3mm wire, 25x25mm opening) and advanced industrial-grade locking mechanisms with provisions for the utility company’s specific keying system. The splice plate mechanism was critical in creating a continuous, formidable barrier that integrated perfectly with the existing posts, eliminating vulnerable gaps.

Outcome: The substation achieved a significant uplift in site security, meeting stringent national critical infrastructure protection (CIP) regulatory requirements. The integrated design minimized visual impact while maximizing protection. The ability to quickly open the double-wing doors for equipment transport, combined with the visual monitoring capabilities of the mesh, streamlined operations and enhanced overall site safety.

"The Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door from PeilingTech exceeded our expectations. Its robust construction and perfect fit with our existing pipe framework were critical to the success of our refinery expansion project. We've seen a noticeable improvement in site security and operational efficiency, reducing risks and streamlining our daily operations." - Mr. Li, Project Manager, Global Energy Company.

Ensuring Trustworthiness: Quality Assurance, Warranty, and Support

At PeilingTech, our commitment to quality extends far beyond the manufacturing floor. We understand that trust is built on reliability, transparency, and unwavering support. Our processes are designed to instill confidence in every client, from initial consultation to decades of operational use, ensuring your investment in a Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door yields long-term value and performance.

- Rigorous Quality Assurance & Certifications: Every Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door undergoes a multi-stage quality control protocol that begins at material procurement and continues through every phase of manufacturing. This includes raw material verification (with material test reports), in-process inspections at each manufacturing stage (e.g., dimensional checks after cutting, weld quality inspections using NDT methods), and a comprehensive final inspection. We are proud to be ISO 9001:2015 certified, signifying our adherence to internationally recognized quality management systems. All testing and inspection records are meticulously maintained and can be provided upon request for full transparency.

- Comprehensive Product Warranty: We stand unequivocally behind the durability, performance, and craftsmanship of our products. Each Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door comes with a standard 5-year warranty on structural integrity and manufacturing defects under normal operating conditions, with extended warranty options available for specific projects. This commitment reflects our profound confidence in the quality of our materials, precision engineering, and skilled fabrication processes.

- Transparent Delivery Cycle: We provide clear, realistic, and diligently managed delivery timelines from the outset of every project. For standard configurations, typical lead times range from 4-6 weeks after design approval and order confirmation. For highly customized or large-scale projects, a detailed, phased project timeline is meticulously developed and shared, factoring in design complexity, specific material sourcing, manufacturing queue, and logistics. Our robust supply chain, optimized production lines, and proactive communication minimize potential delays and ensure on-time delivery.

- Dedicated Customer Support & Technical Assistance: Our highly responsive and knowledgeable customer support team is available from 8 AM to 6 PM (GMT+8), Monday to Friday, to address technical inquiries, provide real-time order status updates, and offer comprehensive after-sales assistance. For major projects, we assign dedicated account managers, ensuring a single point of contact and seamless communication throughout the project lifecycle. We provide comprehensive documentation, including detailed installation guides, maintenance manuals, and troubleshooting tips, with every delivery.

- Long-Term Partnership and Service Life: PeilingTech prides itself on building enduring, long-term relationships with our clients. Beyond initial delivery, we offer ongoing support services, including periodic maintenance recommendations, readily available spare parts supply, and technical upgrades to ensure your Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door continues to perform optimally and securely throughout its impressive operational life, which is engineered to exceed 20-30 years in challenging industrial environments. Our extensive service history, spanning over a decade in providing robust industrial solutions, underscores our reliability.

Frequently Asked Questions (FAQ) about Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door

1. What is the primary function and structural advantage of the "Round Pipe Splice Plate" component?

The "Round Pipe Splice Plate" is a uniquely engineered structural element integrated into the door frame. Its primary function is to allow for the seamless, direct, and incredibly secure attachment of the entire door assembly to existing or newly installed round pipe structures (e.g., structural columns, support frames, fence posts). This eliminates the need for complex, costly, and time-consuming custom field fabrication of additional door frames, reducing installation complexity and ensuring a robust, aesthetically integrated solution with superior structural stability. It acts as a direct, high-strength clamp or embrace around the pipe.

2. What range of materials are typically used for this type of industrial door, and what factors influence material selection?

The main materials include various grades of Carbon Steel (e.g., Q235, Q345, ASTM A36) and Stainless Steel (e.g., AISI 304 for general use, 316 and 316L for enhanced corrosion resistance in harsh chemical or marine environments, and Duplex Stainless Steel for extreme strength and corrosion resistance). Material selection is primarily influenced by the environmental conditions (e.g., humidity, chemical exposure, temperature fluctuations), required structural strength, security level, aesthetic preferences, and project budget. The mesh material is typically galvanized steel or stainless steel to match the door frame's durability and specific environmental needs.

3. How does the "Double Wing" feature enhance operational efficiency in industrial applications?

The "Double Wing" (or double leaf) configuration provides a significantly wider clear opening compared to single-leaf doors of similar height. This is highly beneficial in industrial settings for accommodating the easy and rapid movement of large equipment, heavy machinery, vehicles (e.g., forklifts, pallet jacks), or oversized materials. It also facilitates efficient personnel flow during shift changes or emergencies, thereby enhancing operational flexibility, safety, and reducing logistical bottlenecks within the facility.

4. Can this specialized door be integrated with modern electronic access control systems and what types?

Absolutely. The Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door is designed with full compatibility in mind for integration with a wide array of electronic access control systems. This includes, but is not limited to, electromagnetic locks (mag-locks), electric strikes, card readers (RFID, proximity), biometric scanners (fingerprint, facial recognition), digital keypads, and integration with facility-wide Building Management Systems (BMS) for centralized security monitoring and audit trail capabilities. We can pre-wire and prep the door frame for seamless installation of your chosen access control hardware.

5. What are the key performance benefits of the integrated mesh design for industrial doors?

The mesh design offers several critical benefits for industrial environments: Optimal Ventilation (facilitates natural airflow, crucial for heat dissipation from machinery, dispersion of hazardous gases, or humidity control, potentially reducing energy costs for active ventilation systems); Enhanced Visibility & Surveillance (enables visual inspection and monitoring of the secured area from outside without compromising physical security, enhancing site awareness and safety); and Robust Security (provides a strong physical barrier against unauthorized entry, deterring intruders while allowing light and air to pass). It's particularly useful in areas requiring both stringent access control and environmental management.

6. What international inspection and quality standards does PeilingTech adhere to for these doors?

PeilingTech rigorously adheres to multiple international and industry standards to ensure the highest quality and performance of our doors. These include: ISO 9001:2015 (Quality Management Systems), ensuring consistent production quality; ASTM International standards for material properties (e.g., ASTM A36 for structural steel, ASTM A123 for hot-dip galvanizing, ASTM B117 for salt spray corrosion testing); ANSI/ASME standards for dimensional tolerances and structural design; and relevant regional certifications like CE marking for products designated for the European market, if required by the client. Our welding processes conform to standards such as ISO 3834 and AWS D1.1.

7. What is the expected operational lifespan of a Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door from PeilingTech?

Given the robust materials, advanced manufacturing processes (including precision CNC fabrication and high-quality welding), and superior surface treatments (such as hot-dip galvanizing or multi-layer powder coating), a properly installed and maintained Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door from PeilingTech is engineered for an exceptional operational lifespan. Customers can typically expect a service life of 20-30 years or even more in challenging industrial environments. Regular preventative maintenance, including lubrication of moving parts and periodic inspection of coatings, will further extend its dependable service life and ensure consistent optimal performance.

Further Reading and Industry Insights

For more in-depth understanding of industrial security, structural engineering, and materials science relevant to robust access solutions, consider exploring the following authoritative resources:

- Industry Report: "Industrial Doors Market - Growth, Trends, COVID-19 Impact, and Forecasts (2023 - 2028)" - Mordor Intelligence.

https://www.mordorintelligence.com/industry-reports/industrial-doors-marketThis report provides comprehensive market analysis, including drivers, restraints, opportunities, and segment breakdowns for various industrial door types, highlighting the increasing demand for specialized security and environmental control solutions.

- Academic Article: "Advances in Corrosion Protection of Steel Structures in Industrial Environments: A Review" - Journal of Materials Engineering and Performance (ASM International).

While a specific direct public link often requires a journal subscription, this topic is extensively covered in material science and engineering databases. Search for publications on Google Scholar or reputable engineering society libraries (e.g., ASM International Digital Library, SpringerLink - Materials Science) using terms like "industrial corrosion protection steel" or "hot-dip galvanizing performance". These articles provide scientific insights into the longevity and protective mechanisms of various coatings in harsh settings. - Industry Forum: "Industrial Security & Access Control Best Practices Forum" - Discussions on critical infrastructure protection and plant operations.

For valuable real-world perspectives and technical discussions, active engagement in professional engineering forums is highly recommended. Examples include specific discussion threads on reputable platforms such as Eng-Tips Forums (look for Mechanical or Structural Engineering sections) or specialized industrial plant engineering communities (e.g., Plant Engineering Forums). These platforms often feature experts discussing challenges and solutions for industrial access points, material selection, and security integration in various facility types.

-

Durable & Secure Single Front Door Design Iron | Innovative Architectural SolutionsNewsNov.19,2025

-

Durable Single Door Gate Design Iron Solutions for Security & StyleNewsNov.18,2025

-

Explore Durable & Affordable Simple Single Steel Gate Design SolutionsNewsNov.18,2025

-

One Side Main Gate Design: Efficient Access Solutions for Global ApplicationsNewsNov.15,2025

-

One Side Iron Gate Design – Space-Saving and Durable Gate Solutions for Modern NeedsNewsNov.15,2025

-

One Door Gate Design: Practical Insights & Global RelevanceNewsNov.14,2025