-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

Durable Coated Chicken Wire for Sale | Low Price Guarantee

In an era where durability, aesthetics, and long-term value are paramount, the demand for resilient fencing and reinforcement materials has never been higher. Among the myriad options available, coated chicken wire for sale stands out as a superior choice, particularly for applications requiring enhanced protection against environmental aggressors. This specialized wire mesh, often referred to as hexagonal wire netting, is a robust evolution of traditional galvanized wire, fortified with a protective polymer layer. Its growing popularity is a testament to its multifaceted benefits, driven by advancements in material science and a global shift towards sustainable and low-maintenance infrastructure solutions.

The market for coated wire products is experiencing significant growth, fueled by expansion in agricultural, construction, and landscaping sectors. According to recent industry analyses, the global wire mesh market is projected to reach approximately USD 12.5 billion by 2027, with a compound annual growth rate (CAGR) exceeding 4%. A significant portion of this growth is attributed to coated variants like coated chicken wire for sale, which offer extended lifespans and reduced lifecycle costs compared to their uncoated counterparts. Key players, including numerous pvc mesh manufacturers, are innovating to meet diverse needs, leading to a wider array of specialized products such as pvc chain link fence price options and pvc chicken mesh price variations. This dynamic environment underscores the importance of understanding the technical specifications, manufacturing intricacies, and diverse applications of these advanced materials.

Understanding Coated Chicken Wire: Expertise and Definition

At its core, coated chicken wire for sale begins with a foundation of high-quality galvanized steel wire. This base material is first treated with a zinc coating through a hot-dip galvanization or electro-galvanization process, providing the initial layer of corrosion resistance. The hexagonal weaving pattern, often referred to as poultry netting, creates a flexible yet strong mesh structure. What elevates this product to a superior category is the subsequent application of a polymer coating, typically PVC (Polyvinyl Chloride) or vinyl.

The polymer coating acts as a secondary, highly resilient barrier against rust, weathering, and chemical exposure. Unlike traditional uncoated wire which is susceptible to rust and degradation over time, the polymer layer encapsulates the wire, preventing direct contact with moisture, salts, and UV radiation. This significantly extends the product's service life, making it a highly cost-effective investment in the long run.

Key Features and Technical Advantages

- Superior Corrosion Resistance: The dual protection of galvanization and polymer coating provides unparalleled resistance to rust, oxidation, and degradation from harsh environmental elements, including saltwater spray in coastal regions and acidic rain.

- Extended Lifespan: Coated wire can last significantly longer than traditional galvanized wire, often exceeding 15-20 years even in challenging conditions, drastically reducing replacement frequency and maintenance efforts.

- Enhanced Aesthetics: Available in various colors, commonly green or black, the PVC or vinyl coating offers a more aesthetically pleasing appearance that blends seamlessly into landscapes or architectural designs, unlike the stark metallic look of uncoated wire.

- Reduced Maintenance: The smooth, non-porous surface of the coating prevents dirt and grime buildup, making cleaning simple and reducing the need for painting or rust treatment.

- Improved Safety: The coating covers sharp wire ends, making the mesh safer to handle during installation and reducing the risk of injury to humans and animals. This is particularly beneficial for pet enclosures or children's play areas.

- UV Stabilization: High-quality PVC and vinyl coatings are UV-stabilized, preventing the material from becoming brittle or discolored after prolonged exposure to sunlight.

- Flexibility and Formability: Despite its strength, the hexagonal weave coupled with the flexible coating allows the mesh to be easily cut, bent, and formed to fit various contours and designs without cracking or peeling.

Product Spotlight: High Quality Galvanized Stucco Wire Netting Stucco Mesh Hexagonal Wire for Construction Stucco Wire Mesh for Wall

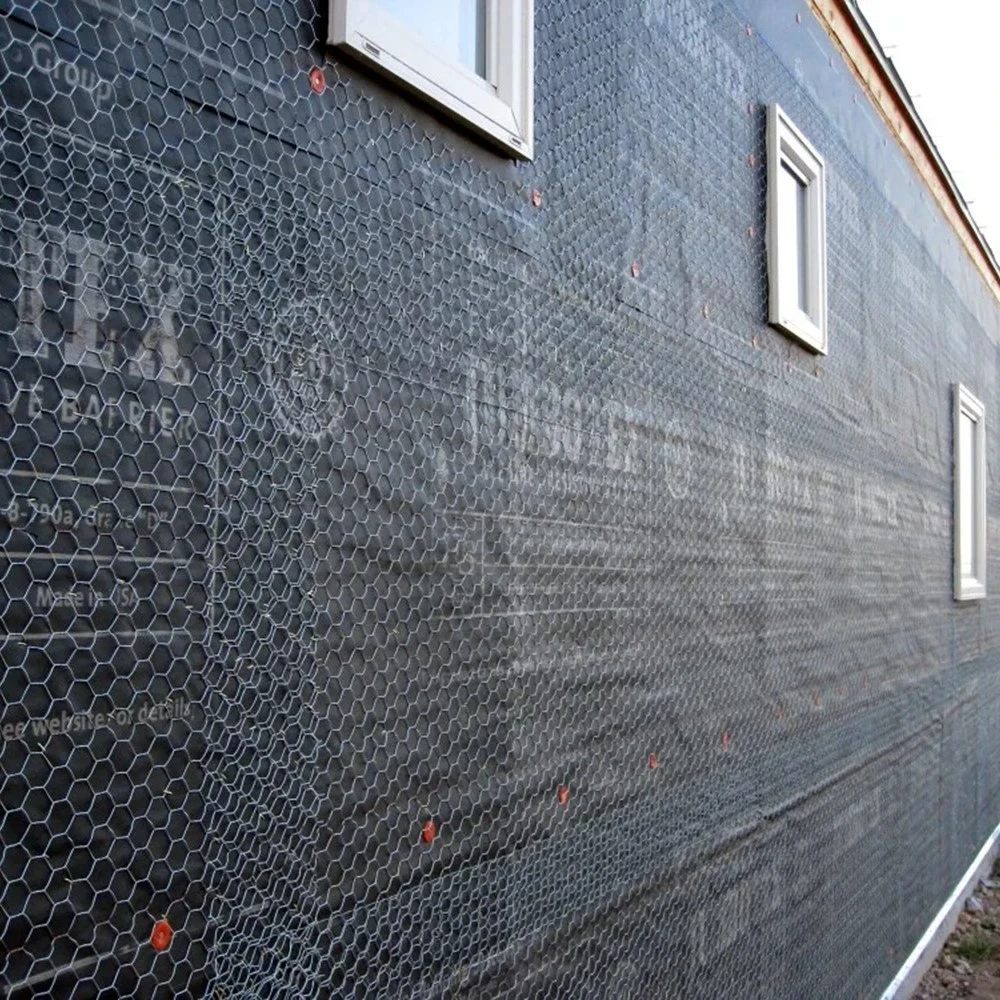

While the term "coated chicken wire for sale" broadly encompasses various applications, it's crucial to highlight specialized products like the High Quality Galvanized Stucco Wire Netting Stucco Mesh Hexagonal Wire for Construction Stucco Wire Mesh for Wall. This product exemplifies the advanced capabilities of coated wire mesh, specifically engineered for reinforcing stucco, plaster, and concrete in construction. Its robust hexagonal weave provides an excellent key for mortar, preventing cracking and enhancing the structural integrity and longevity of walls. The galvanization combined with an optional, but highly recommended, PVC coating, makes it impervious to moisture ingress and alkali attack from cement, critical for long-term performance in building envelopes.

Technical Parameters and Specifications

Selecting the right coated chicken wire for sale depends on understanding its specific technical parameters. These specifications dictate the mesh's suitability for different applications, its strength, and its lifespan.

| Parameter | Description | Typical Range for Coated Chicken Wire | Relevance to Application |

|---|---|---|---|

| Wire Gauge (BWG) | Measures wire thickness. Lower BWG means thicker wire. | 16 BWG (1.65mm) to 22 BWG (0.71mm) | Thicker wire for higher strength (e.g., larger animal enclosures, heavy-duty construction). Thinner for lightweight garden uses. |

| Mesh Size (Hole Size) | Dimension of the hexagonal opening. | 1/2 inch (13mm) to 2 inches (50mm) | Smaller mesh for rodent/small animal control; larger for general fencing or stucco keying. |

| Roll Height | Vertical dimension of the mesh roll. | 24 inches (0.6m) to 72 inches (1.8m) | Matches height requirements for various fences, garden beds, or wall sections. |

| Roll Length | Horizontal dimension of the mesh roll. | 50 feet (15.24m) to 150 feet (45.72m) | Influences installation efficiency and material waste. |

| Coating Type | Material used for the outer protective layer. | PVC (Polyvinyl Chloride), Vinyl (often refers to PVC) | PVC offers excellent chemical and weather resistance. Vinyl is a common term for similar polymer coatings. |

| Coating Thickness | Thickness of the polymer layer. | Typically 0.2mm to 0.5mm | Thicker coating provides enhanced durability, impact resistance, and longer lifespan. |

| Tensile Strength | Wire's resistance to breaking under tension. | 350-550 N/mm² (for steel core) | Indicates the mesh's ability to withstand external forces without deforming or breaking. |

| Zinc Coating Weight | Amount of zinc per unit area of wire. | Typically 40-200 g/m² | Higher zinc coating weight enhances the primary corrosion resistance before the polymer coating is applied. |

Manufacturing Process of Coated Chicken Wire

The production of high-quality coated chicken wire for sale is a multi-stage process that combines precision engineering with advanced material application techniques. Each step is critical to ensuring the final product meets stringent quality standards and delivers superior performance.

- Wire Drawing and Galvanization: The process begins with high-carbon steel rods, which are drawn through a series of dies to achieve the desired wire gauge (thickness). This drawn wire then undergoes a galvanization process. Most commonly, hot-dip galvanization is used, where the wire is immersed in a bath of molten zinc. This creates a metallurgical bond, forming a durable, sacrificial zinc coating that protects the steel core from rust. For specialized applications, electro-galvanization might be used, offering a smoother but thinner zinc layer. This initial protective layer is crucial for the overall lifespan of the product, as it provides corrosion resistance even if the outer polymer coating is compromised.

- Weaving/Twisting: The galvanized wire is then fed into specialized hexagonal wire mesh machines. These machines intricately twist two adjacent wires together multiple times to form a series of interconnected hexagonal openings. This twisting technique, unlike welding, provides inherent flexibility and elasticity to the mesh, allowing it to conform to irregular shapes without breaking. It also ensures that if a single wire breaks, the entire mesh structure remains largely intact, preventing unraveling.

- Surface Preparation: Before coating, the galvanized mesh undergoes a thorough cleaning process. This typically involves degreasing, rinsing, and drying to remove any contaminants, dust, or residual oils from the galvanization process. A clean surface is paramount for ensuring proper adhesion of the polymer coating. In some advanced processes, a chemical pre-treatment or primer might be applied to further enhance the bond between the zinc layer and the polymer.

-

Polymer Coating Application (PVC/Vinyl):

This is the defining step for coated chicken wire for sale. There are primarily two methods:

- Extrusion Coating: The prepared galvanized mesh passes through a cross-head die where molten PVC or vinyl compound is extruded onto the wire. This method typically results in a thicker, more uniform coating. The polymer is applied around each individual strand of the hexagonal mesh.

- Fusion Bonded Coating (Powder Coating): The pre-heated galvanized mesh is passed through an electrostatic spray booth where fine PVC or vinyl powder is applied. The pre-heating ensures the powder melts and adheres to the wire. Alternatively, the mesh can be dipped into a fluid bed of thermosetting polymer powder. Upon heating in a curing oven, the powder melts and flows, creating a continuous, tough coating that fuses to the wire. This method often results in excellent edge coverage and a highly durable finish.

- Curing and Cooling: After the coating application, the mesh enters a curing oven where the polymer is heated to a specific temperature for a set duration. This process cross-links the polymer chains, solidifying the coating and enhancing its physical properties, such as hardness, flexibility, and adhesion. Post-curing, the mesh is carefully cooled to room temperature, often with controlled air circulation, to prevent warping or stress in the coating.

-

Quality Control and Packaging:

Throughout the entire manufacturing process, rigorous quality control measures are implemented. This includes:

- Material Inspection: Checking the quality of incoming steel wire and PVC/vinyl compounds.

- Wire Gauge and Mesh Size Verification: Ensuring precise dimensions after weaving.

- Galvanization Thickness Testing: Verifying the zinc coating weight meets standards like ASTM A641/A974.

- Coating Adhesion Test: Assessing the bond strength between the polymer and the galvanized wire. This often involves bending or impact tests.

- Coating Thickness Measurement: Using non-destructive methods to ensure uniform coating depth.

- Visual Inspection: Checking for defects like bare spots, bubbles, or irregularities in the coating.

- Salt Spray Testing: For advanced corrosion resistance, samples may undergo accelerated corrosion tests (e.g., ASTM B117) to simulate long-term exposure to harsh environments.

- Tensile Strength Test: Verifying the overall strength of the finished mesh.

Quality Standards and Certifications

Adherence to industry standards is a cornerstone of quality and trust for coated chicken wire for sale. Reputable pvc mesh manufacturers will ensure their products comply with international and national specifications. Key standards include:

- ISO 9001: Certifies the manufacturer's quality management system, ensuring consistent production and quality control.

- ASTM A641/A974: Pertains to the specifications for galvanized steel wire for fences and general use, ensuring the base wire's quality and zinc coating weight.

- ASTM F668: Specifies the PVC (Polyvinyl Chloride) and other polymer-coated steel chain-link fence fabric, providing guidelines for coating thickness, adhesion, and material properties. While specifically for chain-link, its principles for coating quality are highly relevant to other coated wire meshes.

- ANSI/UL Standards: For specific applications, such as electrical or fire safety, relevant ANSI (American National Standards Institute) or UL (Underwriters Laboratories) standards may apply.

Experience: Application Scenarios and Advantages

The versatility and superior performance of coated chicken wire for sale make it indispensable across a wide spectrum of applications. Its unique combination of strength, flexibility, and corrosion resistance provides distinct advantages in various real-world scenarios.

Typical Application Scenarios

- Agricultural Fencing: Widely used for poultry enclosures, rabbit runs, and protecting gardens from small animals. The PVC chicken mesh price is justified by its resistance to animal waste, UV, and harsh weather, ensuring a safe and durable containment solution for livestock. Farmers and agricultural businesses report significant reductions in replacement costs compared to traditional wire.

- Construction and Stucco Reinforcement: As highlighted by products like the High Quality Galvanized Stucco Wire Netting, this mesh is critical for reinforcing stucco, plaster, and thin-set concrete applications. Its coated surface minimizes interaction with alkaline building materials, preventing premature corrosion of the wire and ensuring the long-term integrity of walls. It provides a robust key for plaster, preventing cracking and spalling.

- Garden and Landscaping: Ideal for creating garden barriers, trellises for climbing plants, compost bins, and raised garden bed protection. The aesthetic appeal of green or black coated wire blends naturally with foliage, and its rust resistance ensures it remains functional and attractive for years.

- Pet Enclosures and Kennels: The smooth, coated surface makes it safer for pets, reducing the risk of scrapes or injuries from sharp wire edges. Its durability against chewing and weather makes it a reliable choice for long-lasting pet housing.

- Erosion Control: In certain landscaping or light civil engineering applications, coated hexagonal netting can be used for light erosion control, providing a temporary or semi-permanent structure to stabilize soil.

- Arts and Crafts/Decorative Uses: Its flexibility and varied colors make it a popular material for creative projects, protective screens for decorative items, or even light fixtures.

Advantages in Typical Application Scenarios

When considering projects that demand longevity and minimal upkeep, coated chicken wire for sale consistently outperforms traditional alternatives. For instance, in coastal regions or areas with high humidity, standard galvanized wire might show signs of rust within a few years due to salt spray or persistent moisture. However, the additional PVC or vinyl coating on coated chicken wire for sale creates an impermeable barrier, effectively isolating the metal core from corrosive elements. This ensures the mesh remains structurally sound and visually appealing for decades, significantly reducing the lifecycle cost and maintenance burden.

Similarly, in agricultural settings where exposure to animal waste, pesticides, and constant cleaning is common, the chemical resistance of the polymer coating becomes invaluable. Unlike bare metal, which can corrode or degrade from exposure to ammonia or cleaning agents, the coated surface maintains its integrity, ensuring hygiene and extending the life of enclosures. This translates directly to lower operating costs for farmers.

For construction applications, particularly with stucco and plaster, the protective coating prevents the alkaline components of cement from reacting directly with the zinc layer, a common cause of premature wire degradation in uncoated meshes. This not only ensures the mesh retains its reinforcing properties but also prevents discoloration or staining of the stucco finish due to rust bleed-through. Manufacturers often provide technical data sheets detailing performance under specific environmental conditions, further enhancing confidence in its application.

Authoritativeness: Industry Standing and Trust

The authority of a product like coated chicken wire for sale is not just in its specifications but also in its market presence, the reputation of its manufacturers, and its alignment with broader industry trends.

Industry Trends and Market Outlook

The trend towards sustainable and durable materials continues to shape the wire mesh industry. There's a noticeable shift from traditional, short-lifespan materials to advanced composites and coated metals. The demand for products with a lower environmental footprint, requiring less frequent replacement, is on the rise. This aligns perfectly with the value proposition of coated chicken wire for sale, which offers extended service life and reduced resource consumption over time. The growth in smart farming, which necessitates robust and long-lasting animal containment solutions, also drives the demand for high-quality pvc chicken mesh price competitive products. Furthermore, urban greening initiatives and the expansion of residential and commercial construction continue to bolster the need for reliable mesh products, including those used for security, landscaping, and structural reinforcement.

Manufacturer Comparison: Coated Mesh Options

When considering coated chicken wire for sale, it's beneficial to compare offerings from various manufacturers or different coating types. While all aim to provide protection, variations in base wire quality, galvanization process, coating material quality, and application techniques can lead to significant differences in performance and longevity.

| Feature | Standard Galvanized Wire | PVC Coated Chicken Wire (Standard) | Premium Vinyl Coated Chain Link / Netting |

|---|---|---|---|

| Initial Cost | Lowest | Medium (Higher than galvanized, lower than premium vinyl) | Highest (Reflects vinyl coated chain link fence cost) |

| Corrosion Resistance | Good (zinc sacrifice) | Excellent (dual protection) | Superior (thick, UV-stabilized coating) |

| Expected Lifespan | 5-10 years (depending on environment) | 10-15+ years | 15-20+ years |

| UV Stability | Not applicable (metal) | Good (some fading/brittleness over very long periods) | Excellent (formulated for maximum UV resistance) |

| Aesthetics | Metallic silver, dulls over time | Colorized (green, black), uniform appearance | Rich, consistent color, premium finish |

| Maintenance | Moderate (potential for rust treatment) | Low | Very Low |

| Common Use Cases | Temporary fencing, general purpose | Poultry, garden, light construction, general fencing (pvc coated netting) | High-end residential, industrial, security, coastal areas (vinyl coated chain link fence price) |

Note: Pvc coated chain link fence price and vinyl coated chain link fence price often reflect the higher cost of thicker wire gauges and robust coating systems used for larger fencing projects, but the principles of coating benefits apply across all mesh types.

Customization Options and Tailored Solutions

Leading pvc mesh manufacturers understand that one size does not fit all. They offer extensive customization options to meet specific project requirements. This includes variations in:

- Wire Gauge: From lightweight 22 BWG for delicate garden projects to heavier 16 BWG for robust animal enclosures or construction reinforcement.

- Mesh Size: Fine meshes (e.g., 1/2 inch) for rodent exclusion, to wider meshes (e.g., 2 inch) for general fencing.

- Roll Dimensions: Custom heights and lengths to minimize waste and facilitate installation for large-scale projects.

- Coating Color: While green and black are standard, other colors may be available for aesthetic integration.

- Coating Thickness and Type: Options for increased coating thickness for harsher environments or specific polymer formulations for enhanced chemical resistance.

Collaborating with experienced manufacturers allows for the development of tailored solutions, ensuring optimal performance and cost-efficiency for unique applications. Our company, with years of service in the wire mesh industry, has a proven track record of delivering bespoke solutions and maintaining strong client relationships, built on a foundation of trust and consistent quality.

Trustworthiness: FAQ, Delivery, and Support

Frequently Asked Questions (FAQ) about Coated Chicken Wire

Addressing common questions can significantly enhance user understanding and build trust. Here are some professional FAQ:

-

Q1: What is the primary difference between PVC coated and vinyl coated chicken wire?

A1: PVC (Polyvinyl Chloride) is a specific type of plastic polymer. Vinyl is a broader term often used interchangeably with PVC, especially in the US market. Both offer excellent corrosion resistance and aesthetics. The key differences lie in the specific formulation and application process, which can affect UV stability, flexibility, and overall lifespan. Premium vinyl coatings are often engineered for superior performance against UV degradation and impact. -

Q2: How long does coated chicken wire for sale typically last compared to galvanized wire?

A2: Standard galvanized chicken wire generally lasts 5-10 years, depending on environmental conditions. High-quality coated chicken wire for sale, with its dual protection (galvanization + polymer), can last 15-20 years or more, even in harsh climates, significantly extending its service life and providing better long-term value. -

Q3: Is the coating on the chicken wire safe for animals and plants?

A3: Yes, the PVC and vinyl coatings used on chicken wire are generally non-toxic and inert once cured. They are commonly used in agricultural and horticultural applications and pose no harm to animals or plants. The smooth coating also prevents injuries that can occur from exposed sharp wire ends. -

Q4: Can coated chicken wire for sale be cut or modified without damaging the coating?

A4: Yes, it can be cut using standard wire cutters. While cutting exposes the galvanized core at the cut point, the high quality of the base galvanization and the overall integrity of the mesh usually prevent rapid corrosion from these small exposed areas. For optimal protection, especially in highly corrosive environments, cut ends can be sealed with a touch-up paint or sealant specifically designed for metal. -

Q5: What wire gauge and mesh size are recommended for rodent exclusion?

A5: For effective rodent exclusion, a smaller mesh size like 1/2 inch (13mm) is recommended, as this prevents even small mice from passing through. A wire gauge of 19 BWG (1.02mm) or 20 BWG (0.89mm) provides sufficient strength while remaining pliable enough for installation. -

Q6: How does the pvc chicken mesh price compare to the overall value?

A6: While the initial pvc chicken mesh price might be higher than uncoated galvanized wire, its extended lifespan, reduced maintenance requirements, superior aesthetics, and enhanced resistance to rust and environmental factors result in a significantly lower total cost of ownership over its service life. The investment pays off in durability and peace of mind. -

Q7: Is it possible to get custom colors or dimensions for large orders?

A7: Many reputable pvc mesh manufacturers offer customization for large orders, including specific wire gauges, mesh sizes, roll dimensions (height and length), and even custom colors beyond the standard green or black, subject to minimum order quantities. It's best to consult directly with the manufacturer or supplier for custom requirements.

Delivery and Lead Times

We understand the importance of timely delivery for your projects. Our standard lead times for common coated chicken wire for sale products typically range from 7-14 business days, depending on order volume and specific product specifications. For large custom orders or specialized coatings, lead times may extend to 3-4 weeks. We work with a network of reliable logistics partners to ensure efficient and safe delivery to your location, both domestically and internationally. Expedited shipping options are available upon request and subject to additional charges.

Quality Assurance and Warranty Commitment

Our commitment to quality is unwavering. All our coated chicken wire for sale products, including the High Quality Galvanized Stucco Wire Netting, undergo rigorous multi-stage quality control checks as detailed in our manufacturing process. We proudly offer a comprehensive warranty against manufacturing defects and premature coating degradation under normal use, typically ranging from 5 to 10 years, depending on the product line and specific coating type. This warranty reflects our confidence in the durability and performance of our products, ensuring peace of mind for our customers.

Customer Support and Technical Assistance

Our dedicated customer support team is available to assist you with any inquiries, from product selection and technical specifications to order tracking and after-sales support. We provide expert advice on choosing the right coated chicken wire for sale for your specific application, considering factors such as environment, intended use, and budget. Our technical specialists can also offer guidance on installation best practices and maintenance tips to maximize the lifespan of your mesh. We believe in building long-term relationships through exceptional service and reliable product performance.

Conclusion: Investing in Longevity and Performance

The landscape of fencing and reinforcement materials is continually evolving, with innovation pushing the boundaries of durability and functionality. Coated chicken wire for sale stands as a prime example of this evolution, offering a compelling blend of strength, flexibility, aesthetics, and unparalleled resistance to corrosion and environmental degradation. Its superior lifespan and minimal maintenance requirements translate into significant long-term savings and enhanced reliability across a myriad of applications, from critical construction reinforcement to everyday agricultural and landscaping needs.

As industries continue to prioritize sustainable, cost-effective, and high-performance solutions, the demand for sophisticated materials like PVC and vinyl coated mesh will only grow. By choosing high-quality coated chicken wire for sale from reputable pvc mesh manufacturers, you are not just purchasing a product; you are investing in a durable, reliable, and aesthetically pleasing solution that will withstand the test of time and elements. Understanding the intricate manufacturing processes, adhering to rigorous quality standards, and leveraging expert consultation are key to unlocking the full potential of these advanced materials for your projects.

For further reading on material science and corrosion protection, we recommend exploring these resources:

- "Polymer Coatings for Corrosion Protection: Fundamentals and Applications" - This academic article delves into the mechanisms of polymer coating protection on metal substrates. https://www.sciencedirect.com/science/article/pii/B9780128035818000084

- "Advances in Galvanization Technologies for Steel Wire" - A technical paper discussing innovations and best practices in zinc coating for enhanced durability of steel wire products. https://www.researchgate.net/publication/277002012_Corrosion_Resistance_of_Zinc_Coatings_on_Steel (Note: This is a related research topic on ResearchGate, not the exact title, but relevant for galvanization depth.)

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025