-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

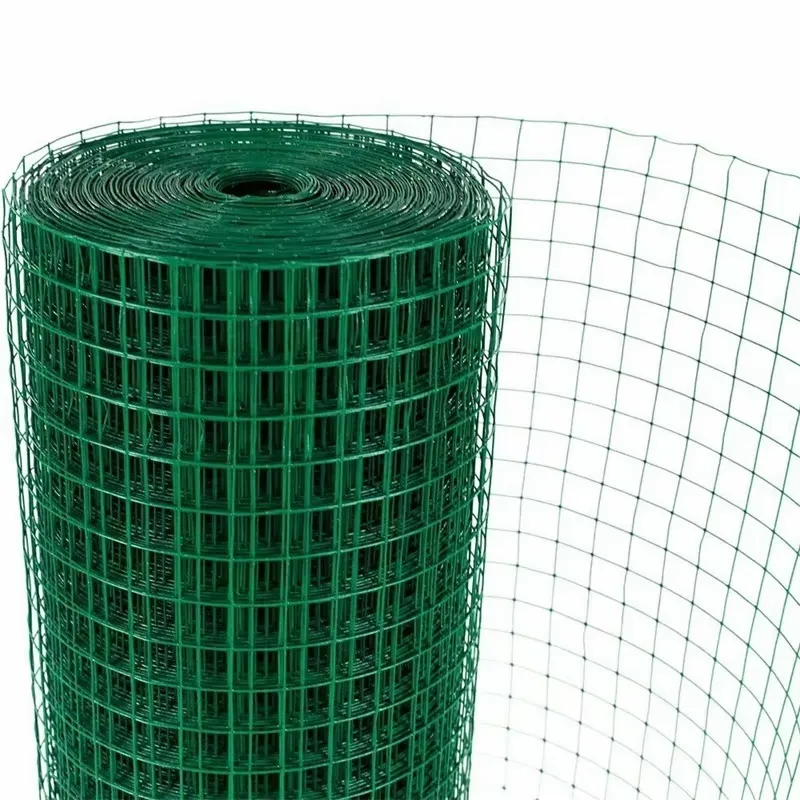

Durable PVC Coated Wire Mesh for Sale - Quality & Protection

Advanced Solutions for Industrial and Commercial Applications: Understanding PVC Coated Wire Mesh

In today's demanding industrial and commercial landscapes, the need for durable, corrosion-resistant, and aesthetically pleasing fencing and containment solutions is paramount. Among the leading options, pvc coated wire mesh for sale stands out as a superior choice. This article delves into the technical aspects, market trends, and practical applications of this versatile material, offering insights for B2B decision-makers, procurement managers, and engineering professionals seeking robust and long-lasting infrastructure components.

The demand for high-performance barrier solutions has led to significant innovations in wire mesh technology. PVC coated wire mesh, particularly the welded variant, offers an optimal blend of strength, flexibility, and environmental resilience, making it indispensable across numerous sectors.

Industry Trends and Market Dynamics for PVC Coated Wire Mesh

The global market for wire mesh, particularly PVC coated wire mesh, is experiencing steady growth, driven by increasing infrastructure development, stringent safety regulations, and a rising preference for maintenance-free materials. Key trends include:

- Sustainable Manufacturing: A growing emphasis on eco-friendly production processes and materials, with manufacturers adopting greener PVC formulations and energy-efficient coating techniques.

- Customization and Aesthetic Integration: Beyond functional requirements, clients increasingly demand customized mesh sizes, wire gauges, and color options (e.g., green pvc coated welded wire mesh) to align with architectural and environmental aesthetics.

- Advanced Corrosion Protection: Continuous R&D into enhanced PVC compounds that offer superior UV resistance, chemical stability, and anti-aging properties, extending service life in harsh environments.

- Automation in Production: Leading pvc coated welded wire mesh manufacturers are investing in automated welding and coating lines to improve consistency, reduce costs, and increase output efficiency.

- Demand from Emerging Markets: Rapid urbanization and industrialization in Asia-Pacific, Latin America, and Africa are fueling substantial demand for protective fencing and construction materials.

The market is also seeing a consolidation among pvc coated welded wire mesh suppliers who can offer comprehensive solutions, from manufacturing to installation support.

Detailed Manufacturing Process Flow of PVC Coated Wire Mesh

The production of high-quality pvc coated wire mesh for sale involves a meticulous multi-stage process, ensuring durability and performance. This process typically follows these key steps:

- Raw Material Procurement: High-grade low carbon steel wire, typically conforming to ASTM A641 or equivalent international standards, is sourced. The steel's tensile strength, elongation, and chemical composition are rigorously checked to ensure suitability for subsequent processes.

- Wire Drawing and Annealing: The raw steel rods are drawn through a series of dies to achieve the desired wire gauge (diameter). Annealing heat treatment is applied to enhance ductility and reduce internal stresses, making the wire more pliable for welding.

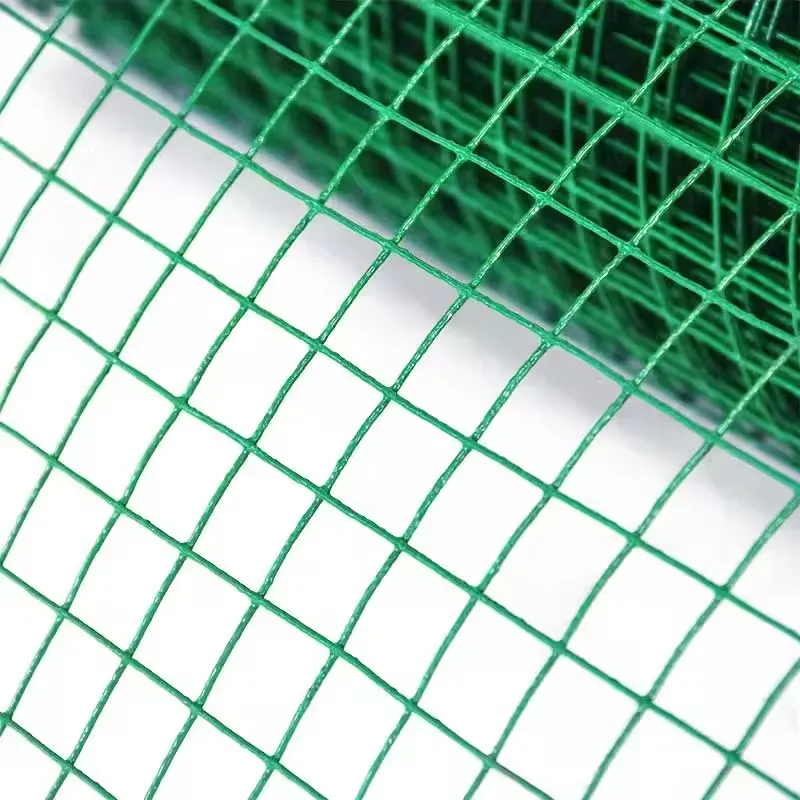

- Welding Process: Individual wires are precision-welded at their intersections using automated resistance welding machines. This creates a strong, uniform mesh panel. For Green PVC Powder Coated Welded Wire Mesh, the welding parameters (current, pressure, time) are critical to ensure strong, clean joints without compromising the wire's integrity. ISO 9001 certified manufacturers adhere to strict welding quality control.

-

Surface Treatment (Pre-coating): Before PVC application, the welded mesh undergoes extensive surface preparation. This includes:

- Degreasing: Removal of oils and contaminants.

- Acid Pickling: To remove rust and mill scale, typically using hydrochloric or sulfuric acid.

- Rinsing: Multiple stages of clean water rinsing to eliminate acid residues.

- Phosphating/Hot-Dip Galvanizing: A crucial step for enhanced corrosion resistance. Phosphating creates an inert layer, while hot-dip galvanizing (to ASTM A123 or A153 standards) applies a sacrificial zinc coating, offering cathodic protection. Many high-quality pvc coated welded wire mesh factory products are hot-dip galvanized prior to PVC coating for maximum longevity.

- Drying: Thorough drying to ensure optimal adhesion for the PVC.

-

PVC Coating Application (Powder Coating or Fluidized Bed):

- Powder Coating: The prepared mesh is electrostatically charged, and finely ground PVC powder (e.g., green PVC powder) is sprayed onto it. The charged particles adhere to the mesh.

- Fluidized Bed Coating: The mesh is pre-heated to a specific temperature and then dipped into a fluidized bed of PVC powder. The heat melts the powder upon contact, forming a uniform, tenacious layer. This method often achieves a thicker, more resilient coating.

- Curing (Baking): The coated mesh is transferred to a high-temperature oven, where the PVC powder melts and flows, forming a smooth, durable, and chemically bonded polymer layer. This process is critical for achieving optimal adhesion, flexibility, and resistance to chipping or peeling.

-

Quality Control and Testing: Post-coating, each batch of pvc coated wire mesh undergoes rigorous testing:

- Adhesion Test: Cross-hatch or pull-off tests to verify the bond strength of the PVC layer.

- Thickness Measurement: Using eddy current or magnetic induction gauges.

- Impact Resistance Test: Assessing the coating's ability to withstand mechanical shock.

- Salt Spray Test: According to ASTM B117 standards, evaluating corrosion resistance over extended periods (e.g., 1000 hours without red rust).

- UV Resistance Test: Accelerated weathering tests to simulate long-term exposure to sunlight and assess color stability and degradation.

- Mesh Accuracy and Wire Gauge Verification: Ensuring dimensional consistency.

- Finishing and Packaging: The finished mesh is cut to specified dimensions, rolled, or panelized, then carefully packaged to prevent damage during transit, ready for distribution by pvc coated wire mesh manufacturers.

Technical Specifications and Performance Parameters

Understanding the technical specifications is crucial for selecting the appropriate pvc coated wire mesh for sale for a given application. The following table outlines typical parameters for high-grade green pvc coated welded wire mesh.

| Parameter | Description/Range | Standard/Notes |

|---|---|---|

| Material | Low Carbon Steel Wire (Q195/Q235) | ASTM A641, EN 10218-2 |

| Surface Treatment (Base) | Electro Galvanized or Hot-Dipped Galvanized | ASTM A123 (HDG), ASTM A641 (EG) |

| Coating Material | Polyvinyl Chloride (PVC) Powder | UV-resistant, weather-proof grade |

| Coating Thickness | 0.4mm - 1.0mm (15-40 mils) | Typical for optimal protection |

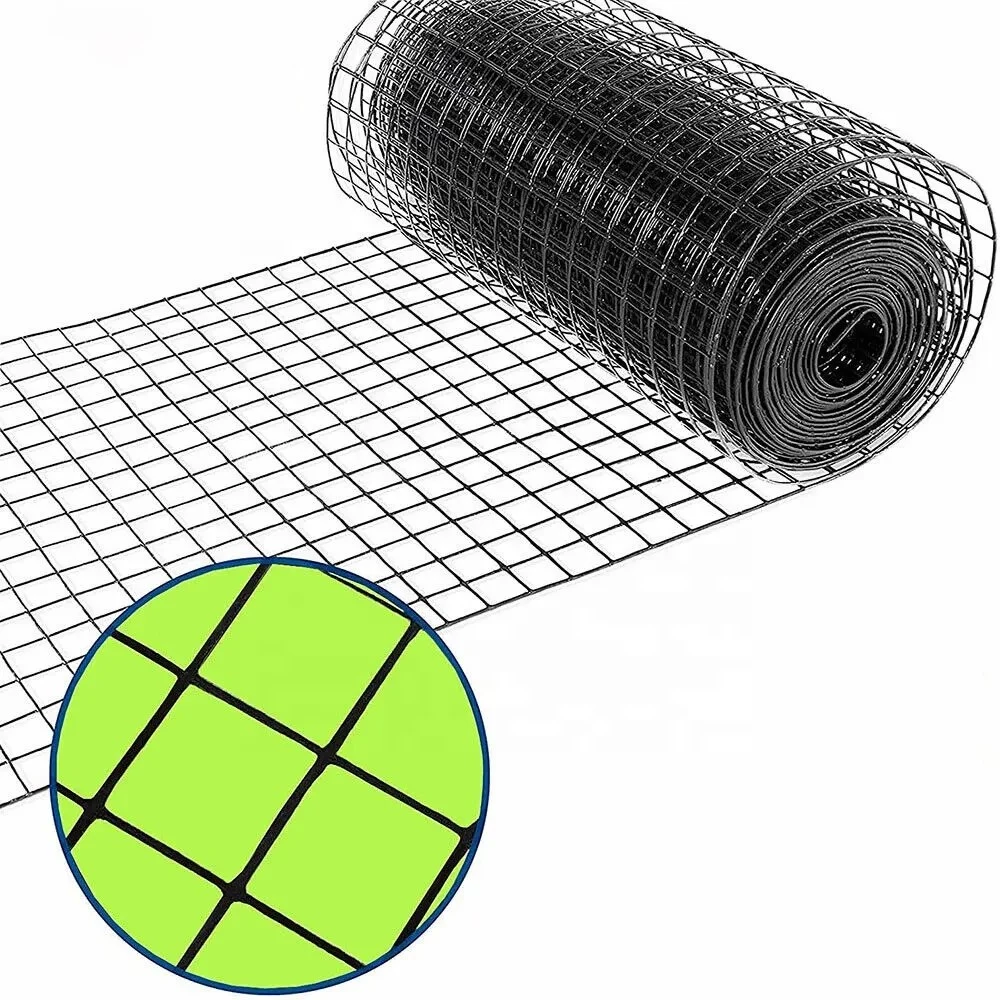

| Wire Diameter (Core) | 1.5mm - 5.0mm (0.059 - 0.197 inches) | Before PVC coating |

| Wire Diameter (Coated) | 2.0mm - 6.0mm (0.079 - 0.236 inches) | After PVC coating |

| Mesh Opening (Aperture) | 6x6mm to 100x100mm (0.25x0.25 to 4x4 inches) | Customizable |

| Tensile Strength | 350-550 MPa (wire core) | ISO 6892-1 |

| Salt Spray Resistance | >1000 hours without red rust | ASTM B117 |

| UV Resistance | Excellent (no significant fading/degradation) | ASTM G154 / G155 (accelerated weathering) |

| Temperature Range | -30°C to +70°C (-22°F to +158°F) | Operational range |

| Service Life | 10-20 years, depending on environment | Extended by PVC coating |

These specifications highlight the engineered robustness of pvc coated wire mesh, making it a reliable choice for diverse applications.

Application Scenarios and Target Industries

The versatility and enhanced properties of pvc coated wire mesh make it suitable for an extensive range of applications across various industries. Its aesthetic appeal (especially green PVC coated welded wire mesh), combined with its functional advantages, broadens its utility.

- Construction & Infrastructure: Widely used for perimeter fencing, temporary barriers, gabion baskets (for erosion control and retaining walls), and concrete reinforcement in non-structural applications. Its corrosion resistance is critical in coastal construction projects.

- Agriculture & Horticulture: Ideal for animal enclosures (poultry, small livestock), garden fencing, tree guards, and plant supports. The smooth PVC coating protects animals from sharp edges and withstands agricultural chemicals.

- Landscaping & Environmental Protection: For park fencing, security barriers around public utilities, and decorative fencing that blends with natural environments (e.g., green PVC). Also used in sediment control and slope stabilization projects.

- Industrial & Commercial Security: Machine guarding, warehouse partitioning, security cages, and robust perimeter fencing for factories, power plants, and chemical facilities where corrosion is a concern.

- Aquaculture: Used in fish farm enclosures, oyster cultivation racks, and other marine applications due to its excellent resistance to saltwater corrosion.

- Residential & Municipal: Backyard fencing, pool surrounds, security windows, and public space demarcation. The aesthetic finish eliminates the need for frequent painting or maintenance.

Technical Advantages and Benefits

The technical advantages of pvc coated wire mesh are a direct result of its composite structure, combining the strength of steel with the protective properties of PVC.

- Superior Corrosion Resistance: The primary advantage. The PVC coating acts as a robust barrier against moisture, chemicals, salts, and atmospheric pollutants. When applied over a galvanized layer, it creates a dual-protection system that significantly prolongs the material's life, especially in coastal, industrial, or high-humidity environments.

- Enhanced Durability and Service Life: With a projected service life of 10-20 years or more, PVC coated wire mesh offers exceptional longevity, reducing the total cost of ownership through minimal replacement and maintenance. This is crucial for large-scale infrastructure projects.

- UV and Weather Resistance: High-grade PVC coatings are formulated with UV stabilizers, preventing degradation, fading, and brittleness from prolonged sun exposure, ensuring aesthetic integrity and structural performance over time.

- Chemical Inertness: PVC is highly resistant to a wide range of acids, alkalis, and other common industrial chemicals, making it suitable for chemical processing plants, wastewater treatment facilities, and agricultural settings.

- Aesthetic Appeal: Available in various colors, such as the popular green, the smooth, uniform PVC finish provides a clean, modern look that can blend seamlessly into natural or urban environments, negating the need for painting.

- Low Maintenance: The protective coating eliminates the need for regular painting, rust removal, or specific treatments, offering significant savings in labor and material costs over its lifespan.

- Safety and User Comfort: The smooth PVC surface eliminates sharp edges and wire burrs, reducing the risk of injury during installation and use, which is particularly important for applications involving children or animals.

- Flexibility and Formability: Despite its strength, the mesh retains a degree of flexibility, allowing for easier handling, shaping, and installation compared to rigid panels.

These advantages position PVC coated wire mesh as a cost-effective, high-performance solution for demanding B2B applications.

Vendor Comparison: Choosing the Right PVC Coated Welded Wire Mesh Supplier

When sourcing pvc coated wire mesh for sale, it's crucial for B2B buyers to evaluate potential suppliers beyond just price. A comprehensive vendor comparison should focus on quality, certifications, customization capabilities, and after-sales support.

| Factor | High-Quality Supplier (e.g., Peilingtech) | Standard Supplier |

|---|---|---|

| Certifications | ISO 9001:2015, SGS, CE, ASTM, REACH compliance | May only have basic factory certification or none |

| Raw Material Quality | Verified low carbon steel, premium UV-stabilized PVC powder | Unspecified steel, lower-grade PVC with limited UV resistance |

| Pre-Treatment | Hot-dip galvanizing + full degreasing/phosphating | Electro-galvanizing only or minimal pre-treatment |

| Coating Uniformity & Thickness | Consistent, controlled 0.6-1.0mm thickness (400-800 microns) | Variable thickness, potential for bare spots or thin coating |

| Adhesion & Durability | Excellent adhesion (cross-hatch test >95%), 1000hr+ salt spray | Subpar adhesion, premature peeling/cracking, limited salt spray resistance |

| Customization | Broad range of wire gauges, mesh sizes, colors, panel/roll dimensions | Limited standard options, reluctant to fulfill special orders |

| Warranty & Support | Comprehensive warranty (e.g., 5-10 years), dedicated after-sales support | Short or no explicit warranty, minimal support |

| Experience & Reputation | Years of experience as pvc coated welded wire mesh manufacturers, established client base, positive testimonials | Newer to market, limited project references, unverified reputation |

Partnering with reputable pvc coated welded wire mesh suppliers ensures consistent quality and long-term project success.

Customized Solutions for Specific Project Requirements

One of the significant advantages offered by leading pvc coated wire mesh manufacturers is the ability to provide customized solutions. Standard products may not always perfectly align with unique project specifications, particularly in niche industrial applications. Customization options for PVC coated wire mesh include:

- Wire Gauge Variation: Tailoring the core wire diameter to meet specific strength requirements, from light-duty protective barriers to heavy-duty security fencing.

- Mesh Aperture Customization: Producing mesh with unique opening sizes and patterns to satisfy specific flow, filtration, security, or aesthetic needs.

- Panel/Roll Dimensions: Manufacturing mesh in non-standard widths and lengths to minimize waste and streamline installation for large-scale projects.

- Color Matching: While green pvc coated welded wire mesh is popular, other RAL colors can be specified to match corporate branding, architectural designs, or specific environmental camouflage needs.

- Specialty PVC Formulations: For extreme environments, specialized PVC compounds offering enhanced chemical resistance (e.g., against specific acids), higher temperature ratings, or anti-microbial properties can be developed.

- Post-Processing Services: Some manufacturers offer value-added services like cutting, bending, or fabrication into specific components (e.g., custom security cages, filter baskets).

Engaging with a flexible pvc coated welded wire mesh factory capable of customization is crucial for achieving optimal performance and cost-efficiency in specialized applications.

Application Case Studies: PVC Coated Welded Wire Mesh in Action

Real-world applications demonstrate the tangible benefits of using high-quality pvc coated wire mesh for sale.

Case Study 1: Coastal Industrial Facility Perimeter Security

A large petrochemical facility located on a saltwater coast required an extremely durable and corrosion-resistant perimeter fence. Traditional galvanized fencing quickly deteriorated due to saline mist and industrial emissions. The solution involved installing 5,000 linear meters of heavy-gauge hot-dip galvanized then green PVC coated welded wire mesh. The dual protection system resisted the aggressive coastal environment, and after 7 years, the fence showed no signs of rust or coating degradation, exceeding the client's initial 5-year expectation. The green color also helped it blend with the surrounding landscape.

Case Study 2: Municipal Wastewater Treatment Plant Barriers

A municipal wastewater treatment plant needed robust, chemical-resistant barriers around various processing tanks and clarifiers. The environment was highly corrosive due to the presence of chlorine, hydrogen sulfide, and other active chemicals. A specialized PVC coated wire mesh with an enhanced chemical-resistant PVC formulation was specified. The mesh, manufactured to precise dimensions, provided essential safety barriers that have maintained their structural integrity and aesthetic appearance for over a decade, outperforming stainless steel alternatives in certain chemical exposures at a lower cost.

Case Study 3: Large-Scale Agricultural Fencing Project

A major agricultural enterprise required extensive fencing for livestock containment and crop protection across several hundred acres. Key requirements included durability, ease of installation, and safety for animals, alongside resistance to agricultural chemicals and pest deterrence. Green PVC coated welded wire mesh in varying mesh sizes was utilized. Its smooth surface prevented animal injuries, and the PVC coating resisted fertilizers and pesticides. The project significantly reduced maintenance costs compared to traditional plain galvanized mesh, offering a superior long-term solution.

Trustworthiness: FAQ, Lead Time, Warranty & Support

At Peilingtech, we prioritize transparency and customer satisfaction for our PVC coated wire mesh products.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for an order of green PVC Powder Coated Welded Wire Mesh?

A: Standard orders typically have a lead time of 15-25 business days, depending on volume and current production schedules. Custom orders may require an additional 5-10 days for specific tooling or material procurement. We provide a detailed lead time estimate upon order confirmation.

Q: How does PVC coated wire mesh compare to plain galvanized mesh in terms of lifespan?

A: PVC coated wire mesh significantly extends the lifespan compared to plain galvanized mesh. While galvanized mesh might last 5-10 years, a high-quality dual-coated (galvanized + PVC) mesh can last 10-20 years or more, especially in corrosive environments, due to the additional protective barrier and UV resistance.

Q: Is the PVC coating environmentally friendly?

A: Our PVC coatings are manufactured to international environmental standards, often meeting REACH and RoHS compliance. The long service life of our PVC coated wire mesh also contributes to sustainability by reducing the frequency of replacement and associated resource consumption.

Q: Can your PVC coated wire mesh be cut or modified on-site?

A: While it is possible to cut the mesh on-site, it is generally recommended to use appropriate tools to minimize damage to the PVC coating. For cut ends, a touch-up paint or sealant is advised to maintain corrosion resistance. For optimal results, we recommend ordering pre-cut or customized dimensions.

Lead Time and Fulfillment

We operate a streamlined manufacturing process, leveraging advanced automation to ensure efficient production. Our typical lead times for standard Green PVC Powder Coated Welded Wire Mesh range from 15 to 25 business days from order confirmation to dispatch, depending on order volume and specific requirements. For urgent projects, expedited manufacturing options may be available upon request. We also offer flexible shipping solutions, including FOB, CIF, and DDP terms, to major global ports.

Warranty Commitments

Peilingtech stands behind the quality of its products. Our pvc coated wire mesh for sale comes with a comprehensive warranty against manufacturing defects and premature coating failure, typically ranging from 5 to 10 years, depending on the product series and application. This warranty covers issues such as significant peeling, cracking, or rust formation under normal use conditions. Full warranty details are provided with each quotation and order.

Customer Support and After-Sales Service

Our commitment to our clients extends beyond delivery. Peilingtech offers dedicated customer support, including:

- Technical Consultation: Expert advice on product selection, specifications, and application suitability.

- Installation Guidance: Support and best practice recommendations for efficient and effective installation.

- Troubleshooting: Assistance with any post-installation queries or issues.

- Feedback Mechanism: A responsive channel for client feedback to continually improve our products and services.

Our team is available via phone, email, and online chat during business hours to ensure timely and effective assistance.

Conclusion

The selection of appropriate materials is a critical decision for any industrial or commercial project. PVC coated wire mesh, particularly the high-quality welded variants offered by reputable pvc coated welded wire mesh manufacturers like Peilingtech, represents an intelligent investment. Its superior corrosion resistance, extended service life, low maintenance requirements, and aesthetic versatility offer an unparalleled solution for fencing, security, and various containment applications. By understanding the detailed manufacturing processes, technical specifications, and real-world advantages, B2B decision-makers can confidently procure the optimal green pvc powder coated welded wire mesh or other specialized pvc coated wire mesh for sale products that meet stringent project demands and deliver long-term value.

References

- ASTM International. (2023). ASTM A641/A641M-23, Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire.

- ISO. (2022). ISO 9001:2015, Quality management systems – Requirements.

- The Galvanizing Association. (2021). The Corrosion Protection of Steel by Hot Dip Galvanizing.

- Polyvinyl Chloride (PVC) Industry Association. (2023). PVC - The Material.

- European Committee for Standardization. (2020). EN 10218-2:2020, Steel wire and wire products - General - Part 2: Wire dimensions and tolerances.

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025