-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Galvanised Wire Mesh Panels: Durable, Rustproof, Fast Fit?

Field Notes: The 3D Era of Galvanised Wire Mesh Panels for Real-World Security

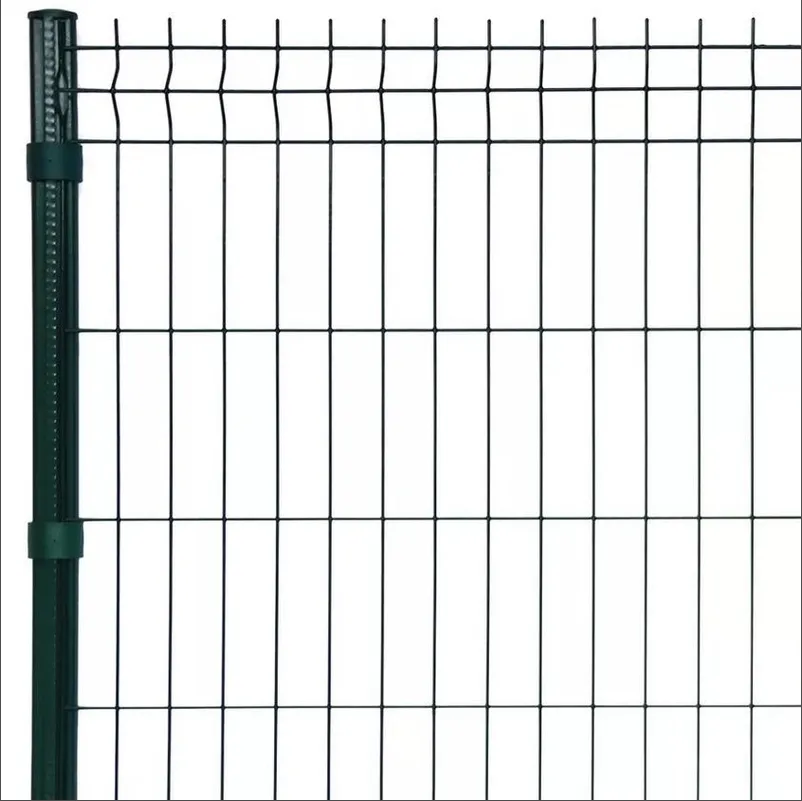

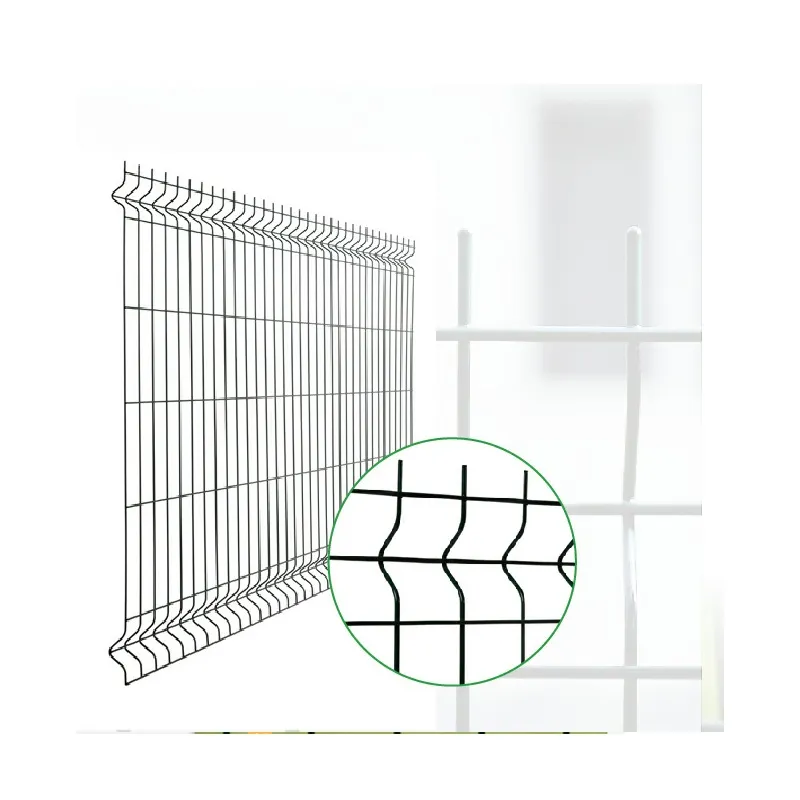

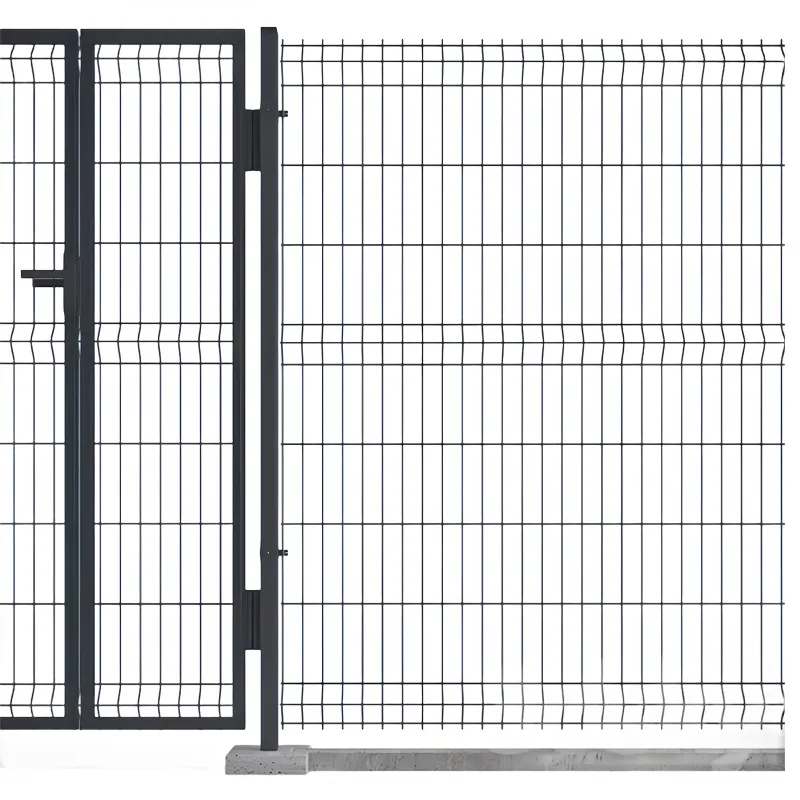

If you're comparing galvanised wire mesh panels this season, the headline is simple: 3D welded geometry plus eco-aware coatings are setting the pace. I’ve walked enough sites—schools, airports, solar farms—to know what survives the weather and the forklift test. This Sustainable Galvanized PVC Powder Coated 3D Welded Wire Panel Fence (a mouthful, I know) takes the practical route: rigid welds, V-bends for stiffness, and coatings that stand up to salt and sun.

What’s trending (and why it matters)

- 3D V-bend stiffness without heavy posts—fewer foundations, faster installs.

- Low-VOC powder coats over zinc; sustainability is no longer just a brochure line.

- Higher visibility for CCTV; opaque barriers are out unless you need anti-view.

- Quick lead times matter; construction schedules rarely forgive delays.

Product snapshot: 3D welded rigidity, clean sightlines

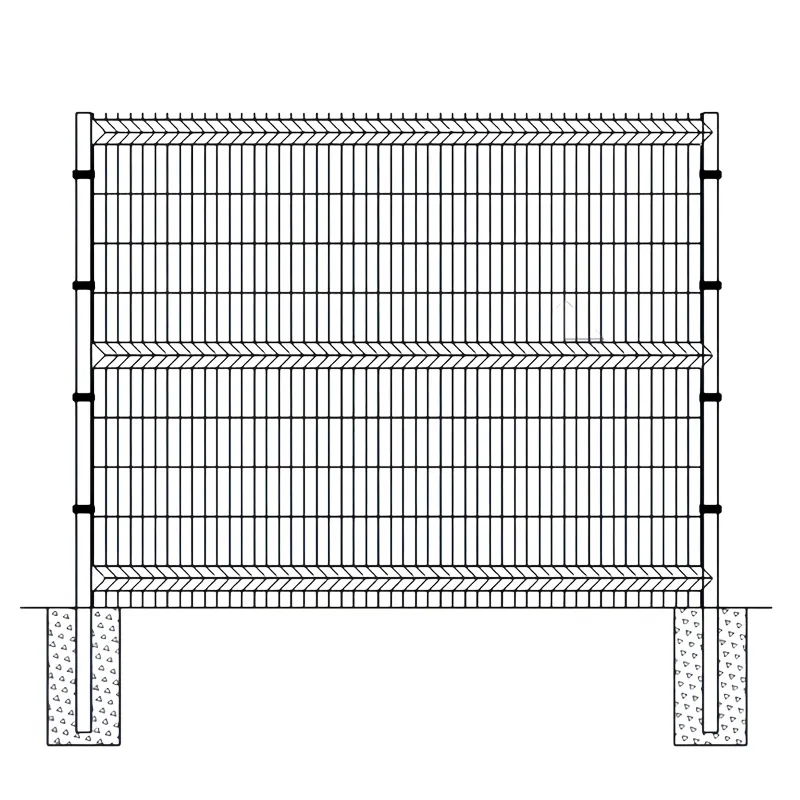

Made from high-quality carbon steel wire, horizontal and vertical wires are resistance-welded at each intersection, then zinc-coated and PVC powder coated. The longitudinal V-curves are not just for looks—they change with height to keep panels rigid without over-spec’ing the posts. In practice, that means fewer callbacks.

| Parameter | Typical Value | Notes (≈ real-world) |

|---|---|---|

| Panel height × width | 1.2–2.4 m × 2.5–3.0 m | Custom sizes available |

| Mesh aperture | 50 × 200 mm (standard) | Other apertures on request |

| Wire diameter | 4.0–5.0 mm | Balanced strength/weight |

| V-bends per panel | 3–5 (by height) | Increases rigidity |

| Zinc coating | ≥ 60–80 g/m² (pre-galv) or hot-dip per ISO 1461 | Environment drives choice |

| PVC powder coat | ≈ 80–120 μm | RAL colors incl. 6005/7016/9005 |

| Weld shear strength | ≥ 450 N junction | Factory test average |

Process & quality, briefly

Materials: low-carbon steel wire, controlled chemistry for weldability. Methods: automatic resistance welding, zinc (pre-galvanized or hot-dip), PVC powder coating, thermal curing. Testing: salt spray (ISO 9227, ≥ 500–720 h NSS typical), adhesion (ASTM D3359, 4B–5B), bend test (ISO 1519), dimensional tolerance (EN 10223-7). Service life: ≈ 10–20 years depending on coastal exposure; inland sites do better. Certifications: ISO 9001 QMS; RoHS-compliant powders; CE-related documentation available where applicable.

Where they’re used (and what people tell me)

- Railways, airports, schools, factories, residential parks, stadiums, gardens—pretty much the usual suspects.

- Many customers say visibility for CCTV stays crisp while deterring casual trespass.

- Maintenance teams like the clip systems—less fuss during panel swaps.

galvanised wire mesh panels case notes, quick-fire:

- Airport perimeter (SEA): switched from chain-link; patrol visibility improved; vandalism down ≈ 30% year-on-year.

- Secondary school (UK): 2.0 m panels with RAL 6005; PTA liked the unobtrusive look—soft landscaping still visible.

- Solar farm (AU): hot-dip option; dust, UV, and wind loads handled better than expected, to be honest.

Vendor comparison (what to watch)

| Vendor | Coating system | Salt-spray (≈) | Lead time | MOQ | Certs | Notes |

|---|---|---|---|---|---|---|

| Peiling Tech (Hebei, CN) | Pre-galv + PVC; hot-dip option | 500–720 h | 2–4 weeks | ≈ 200 panels | ISO 9001, RoHS | Balanced cost/rigidity; origin: Room 818, Lijing INTL BLDG, No.681 Xinhua Rd, Shijiazhuang, Hebei |

| Vendor B (EU) | Hot-dip + polyester | 720–1000 h | 4–6 weeks | ≈ 150 panels | ISO 9001/14001 | Higher corrosion budget |

| Vendor C (Local) | Pre-galv only | 240–480 h | 1–3 weeks | ≈ 50 panels | — | Budget; inland use recommended |

Customization & install tips

- Heights 1.2–2.4 m; posts with clamp bars or clip sets; swing/slide gates to match.

- Edges: 30 mm top overhang acts as a mild anti-climb—useful near public paths.

- Foundations: to be honest, soil dictates more than brochures—go deeper on soft ground.

If you need coastal resilience, specify hot-dip zinc to ISO 1461 plus UV-stable polyester topcoat. For school sites, the standard system hits the sweet spot. Either way, galvanised wire mesh panels keep maintenance lean.

Bottom line

The 3D welded format is not hype; it’s a practical evolution. Specify clearly—aperture, wire gauge, coating route—and you’ll get panels that look smart on day one and still pass the fingernail test years later. For most projects, galvanised wire mesh panels like these strike a sensible balance of security, visibility, and cost.

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

- BS EN 10244-2: Steel wire and wire products — Non-ferrous metallic coatings.

- ISO 9227: Corrosion tests in artificial atmospheres — Salt spray tests.

- ASTM D3359: Measuring adhesion by tape test.

- EN 10223-7: Steel wire and wire products — Fencing products.

- ISO 9001: Quality management systems — Requirements.

-

T Post Drivers for Sale – Heavy-Duty Steel, Fast InstallNewsNov.17,2025

-

Coconut Palm Hanging Baskets, Wall-mounted Coco Liner PotNewsNov.17,2025

-

Hot Sale L Shape Post For Garden Wire Fence | Heavy-DutyNewsNov.17,2025

-

Iron Shepherd Hook—Rust-Resistant Outdoor Garden Decor MetalNewsNov.10,2025

-

Hot Sale Customized Wood & Iron Mesh Fence Post Pyramid CapsNewsNov.10,2025

-

Outdoor Decor Metal Arched Flower Bed Edging No-Dig PanelsNewsNov.10,2025