-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

Jul . 29, 2025 17:20

Back to list

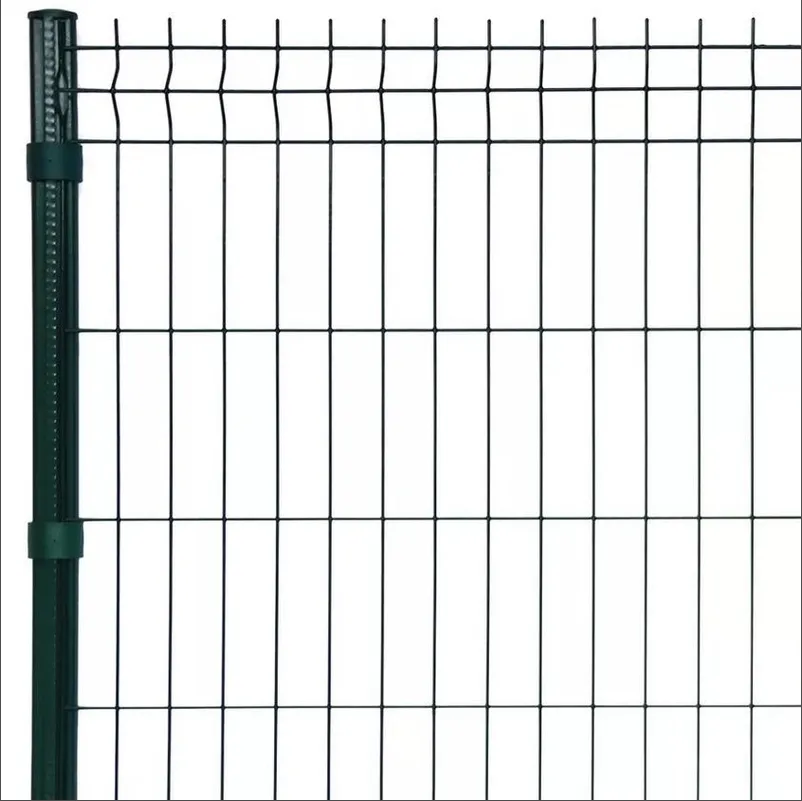

High Quality Galvanised Wire Mesh Panels for Fencing Solutions

As galvanised wire mesh panels continue to revolutionize security, perimeter, and construction solutions worldwide, industry stakeholders seek advanced, sustainable, and customizable products that guarantee durability, safety, and adaptability. This in-depth article explores galvanised wire mesh panels—specifically the Sustainable Galvanized PVC Powder Coated 3D Welded Wire Panel Fence For Building Construction—including its technical specifications, manufacturing process, industry applications, and real-world cases. Supported by comparative data, visualized trends, and expert FAQ, discover why innovative solutions like galvanized welded wire fence panels, 3d welded wire mesh fence, gal mesh fence panels, and similar products lead today's market.

1. Industry Trends of Galvanised Wire Mesh Panels & Fencing Solutions

- Market Growth: Global demand for galvanised wire mesh panels is expected to grow at a CAGR of 5.3% (2022-2028), primarily driven by rapid urbanization, increased infrastructure investments, and focus on sustainable building materials.[Source: Grand View Research]

- Adoption in New Sectors: Sectors like oil & gas, petrochemicals, water management, and agricultural fencing actively choose galvanized hog wire fence and galvanized wire mesh fence panels due to enhanced anti-corrosive technology.

- Higher Performance Demand: Customers seek welded mesh galvanised wire panel solutions with longer service life (>15 years in harsh environments), requiring compliance with ISO 9001, ANSI A392.1, and related testing standards.

2. Technical Specifications & Parameters of Galvanised Wire Mesh Panels

| Panel Type | Wire Diameter (mm) |

Mesh Size (mm) |

Surface Treatment | Max Length (m) |

Corrosion Resistance (Salt Spray, hrs) |

Service Life (Years) |

Industry Application |

|---|---|---|---|---|---|---|---|

| Galvanized Welded Wire Fence Panels | 3.0 – 5.0 | 50x200 / 75x150 | Hot-dip / Electro Galvanized | 3 – 6 | >720 | 10–20 | Construction, Residential, Highway |

| 3D Welded Wire Mesh Fence | 4.0 – 6.0 | 50x200 / 100x300 | Galvanized + PVC/Powder Coated | 2.5 – 3 | >1000 | 15–25 | Building, Energy, Logistics |

| Gal Mesh Fence Panels | 2.5 – 5.0 | 50x50 / 100x100 | Galvanized | 2.5 – 6 | 600 - 1000 | 8–18 | Farming, Security, Landscaping |

| Galvanized Hog Wire Fence | 3.5 – 5.0 | 50x100 / 75x150 | Hot-dip Galvanized | 2.5 – 4 | 900+ | 10–20 | Livestock, Agriculture |

| Galvanised Wire Mesh Sheets | 1.8 – 5.0 | 25x25 / 50x50 | Electro/Hot-dip Galvanized | 1.8 – 3 | 500 - 1200 | 8–22 | DIY, Industry, Architecture |

3. Technical Trend Analysis (Data Visualization)

4. Manufacturing Process: Galvanised Wire Mesh Panels

Manufacturing of advanced galvanised wire mesh panels—particularly the Sustainable Galvanized PVC Powder Coated 3D Welded Wire Panel Fence For Building Construction—involves a streamlined process ensuring durability, anti-corrosion, and customizable dimensions. Below is a process flow with explained key nodes:

1. Raw Material Selection

Premium carbon steel wires (ISO 16120-2 certified) are selected for tensile strength and ductility.

Premium carbon steel wires (ISO 16120-2 certified) are selected for tensile strength and ductility.

→

2. Wire Drawing

Cold-drawing for tight diameter tolerance (±0.02mm); surface cleaning to remove oxides and oils.

Cold-drawing for tight diameter tolerance (±0.02mm); surface cleaning to remove oxides and oils.

→

3. Welding

Automatic CNC mesh welding. Spot-welded at every cross point; conforms to ANSI A392.1.

Automatic CNC mesh welding. Spot-welded at every cross point; conforms to ANSI A392.1.

→

4. Galvanization

Hot-dip or electro galvanizing; achieves zinc layer ≥80g/m² (ISO 1461).

Hot-dip or electro galvanizing; achieves zinc layer ≥80g/m² (ISO 1461).

→

5. PVC / Powder Coating

Eco-friendly powder/PVC layer applied (70-120μm); ensures double anti-corrosion.

Eco-friendly powder/PVC layer applied (70-120μm); ensures double anti-corrosion.

→

6. Inspection & Packaging

Final check (IEC 60068-2-11); thickness, mesh accuracy, salt spray test; sealed eco-packaging.

Final check (IEC 60068-2-11); thickness, mesh accuracy, salt spray test; sealed eco-packaging.

For an interactive process demonstration, watch:

Galvanised Wire Mesh Panel Manufacturing Video (YouTube)

Galvanised Wire Mesh Panel Manufacturing Video (YouTube)

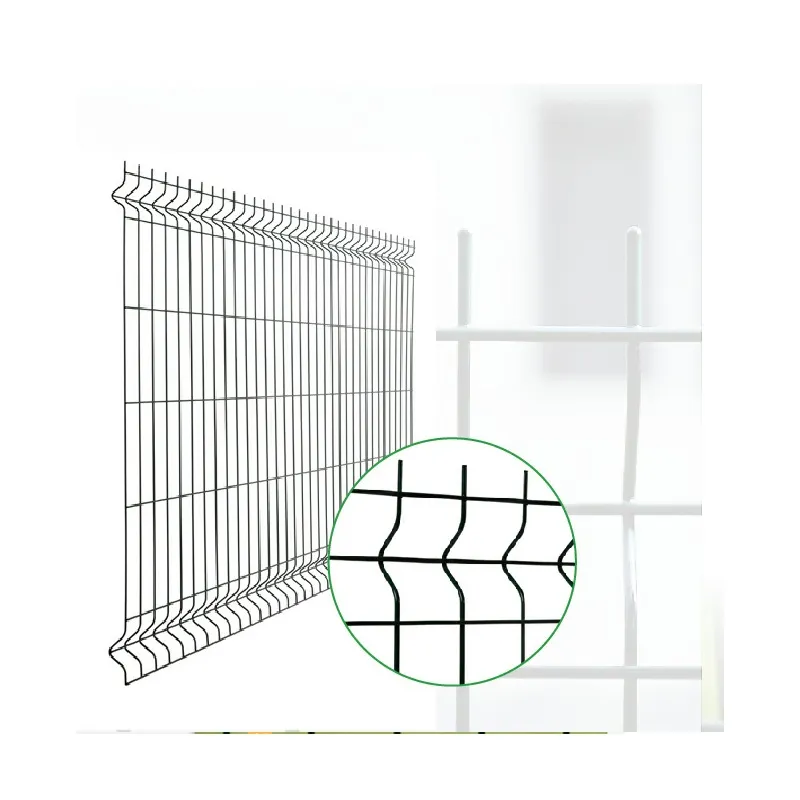

5. Product Highlight: Sustainable Galvanized PVC Powder Coated 3D Welded Wire Panel Fence

- Material Quality: Premium Q195/Q235 carbon steel wire, zinc coating ≥ 80g/m², PVC powder layer 100μm.

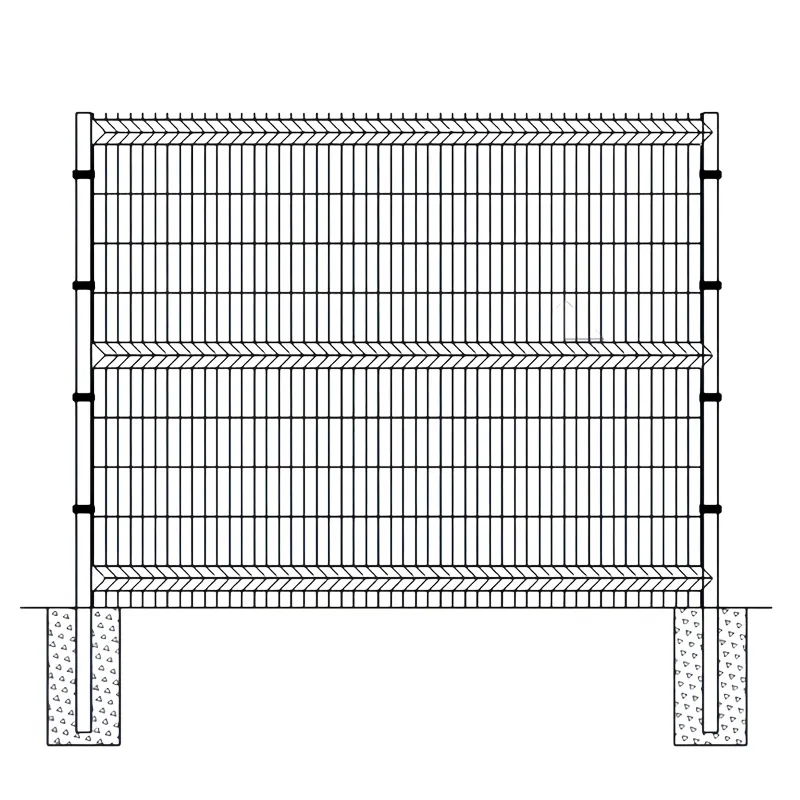

- Size Options: Height 1.2–2.4m, width 2.0–3.0m, post spacing 2–3m.

- Surface & Color: Hot-dip galvanised + 70–120μm powder/PVC, customizable RAL colors.

- Mechanical Strength: Weld shear >50kgf/point (ISO 15630-2), panel bending resistance enhanced by 3D V-beam.

- Environmental Performance: 1000+ hours salt spray resistance, 15–20 years service life, fully recyclable.

- Certification: ISO 9001, EU CE, Reach, SGS, and third-party testing reports.

6. Product Comparison: Galvanized Welded Wire Fence Panels vs. Alternatives

| Product | Corrosion Resistance (hrs) | Coating Type | Service Life (years) | Customization | Compliance |

|---|---|---|---|---|---|

| PVC Powder Coated 3D Welded Panel | 1000+ | Hot-dip + PVC | 15–20 | Yes | ISO9001, CE, SGS |

| Ordinary Galvanized Panel | 500–650 | Galvanized Only | 8–13 | Limited | Factory QA |

| Chain Link Fence | 500 (avg.) | Galvanized / PVC | 8–10 | No | Basic |

| Traditional Hog Wire | 650 | Hot-dip | 10–15 | Partial | — |

7. Data Visualization: Key Technical Indicators

8. Custom Solutions and Service Capabilities

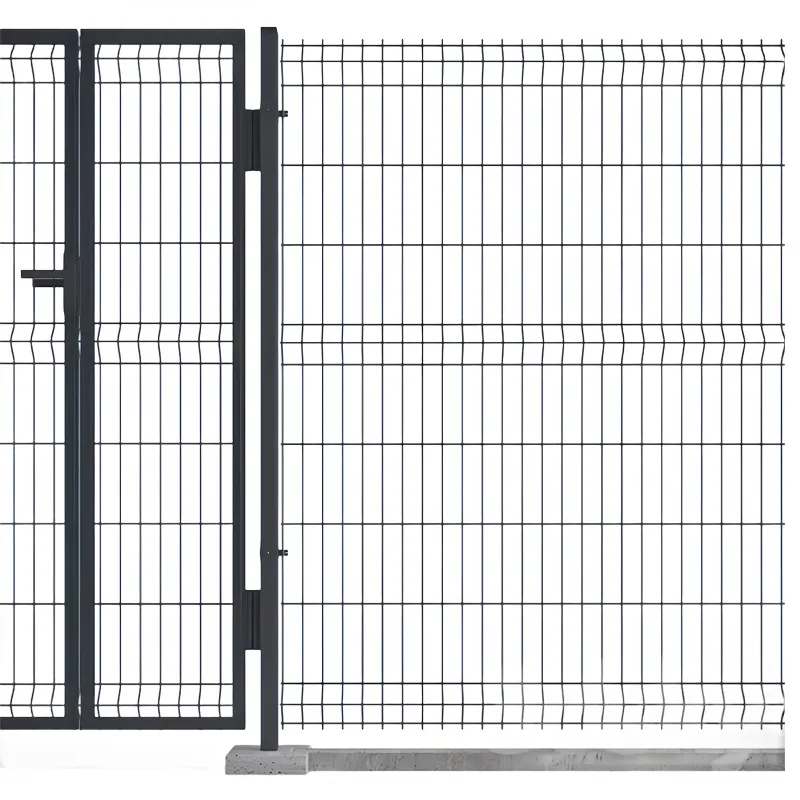

- Dimension Customization: Any mesh, wire diameter, height, or panel length is available upon request for unique site requirements.

- Advanced Coating: Choose color/texture for PVC or powder coating to match architectural or landscape aesthetics.

- Pre-installed Accessories: Customized gates, brackets, security spikes, or CCTV base plates can be manufactured alongside panel orders.

- Project Engineering Service: From design to site delivery, technical drawings and on-site installation guidance provided.

- Third-Party Inspection: SGS, BV, or customer-appointed inspection before shipment. All panels are tested per ISO and ANSI standards.

9. Application Scenarios: Case Studies

Case 1: Petrochemical Facility Perimeter, Singapore (2023)

Challenge: Corrosive coastal environment, strong wind load, 24/7 security.

Solution: Sustainable Galvanized PVC Powder Coated 3D Welded Panel Fence, height 2.4m, hot-dip + powder-coated, customized security clamps.

Result: Passed 1000h salt spray test, 15-year minimum service expected, endorsed by SGS inspection.

Challenge: Corrosive coastal environment, strong wind load, 24/7 security.

Solution: Sustainable Galvanized PVC Powder Coated 3D Welded Panel Fence, height 2.4m, hot-dip + powder-coated, customized security clamps.

Result: Passed 1000h salt spray test, 15-year minimum service expected, endorsed by SGS inspection.

Case 2: City Water Treatment Plant, Norway (2022)

Challenge: Icing, humidity, public safety.

Solution: Galvanised wire mesh panels + anti-slip posts, mesh 50x200mm, low-temperature powder coating.

Result: No corrosion after 3 winters; praised for quick installation and zero maintenance.

Challenge: Icing, humidity, public safety.

Solution: Galvanised wire mesh panels + anti-slip posts, mesh 50x200mm, low-temperature powder coating.

Result: No corrosion after 3 winters; praised for quick installation and zero maintenance.

Case 3: Livestock Farming and Hog Wire Fencing, Australia

Challenge: Livestock pressure, farm chemical exposure.

Solution: Heavy 5.0mm galvanized hog wire fence, reinforced panel structure.

Result: Secure animal containment, 20+ years anticipated service, strong customer feedback.

Challenge: Livestock pressure, farm chemical exposure.

Solution: Heavy 5.0mm galvanized hog wire fence, reinforced panel structure.

Result: Secure animal containment, 20+ years anticipated service, strong customer feedback.

10. Customer Experience & Industry Certification

- Long-term Performance: Reports from water industry, city security, and logistics park users confirm panel service life >15 years.

- Authority: All galvanised wire mesh panels certified for ISO 9001, CE mark, and SGS third-party test documentation available.

- Customer Support: 24/7 technical hotline, free design consultation, and worldwide shipping & logistics solutions.

- Quality Commitment: Factory warranty up to 12 years depending on surface treatment and environment, with clear after-sales process.

- Key Clients: Partnerships with Sinopec, Stadtwerke Hamburg, Suez, New York MTA, and more global leaders.

Lead Time: Standard products: 5–10 days

Sample Policy: Free panel samples (shipping extra) within 48 hours

Warranty: 10–15 years depending on coating type

Support: Engineering solution team, installation field support, 7/24 online service.

Contact Sales: sales@peilingtech.com

Sample Policy: Free panel samples (shipping extra) within 48 hours

Warranty: 10–15 years depending on coating type

Support: Engineering solution team, installation field support, 7/24 online service.

Contact Sales: sales@peilingtech.com

11. Professional FAQ for Galvanised Wire Mesh Panels

Expert FAQ

Q1: What are the main materials for welded mesh galvanised wire mesh panels?

A: Mainly Q195, Q235 carbon steel; sometimes stainless steel for specialty. Wire must be ISO 16120/EN 10244 compliant and low-residue carbon for better welding strength.

Q2: What standards are followed for panel welding quality?

A: ANSI A392.1, ISO 15630-2, and sometimes ASTM A974 for weld shear and mesh alignment. Regular pull-test and visual inspection before shipment.

Q3: What is the typical mesh opening, and how is it selected?

A: Common sizes: 50x200mm, 75x150mm, 100x300mm. Selected based on security level, visual transparency, or animal containment specification. Custom mesh sizes available.

Q4: What coating options are available for galvanized welded wire fence panels?

A: Hot-dip galvanization (up to 275g/m²), or eco-friendly electro-galvanization for indoor/low-corrosion conditions. Plus PVC or polyester powder coating (70–120 μm) for severe environments or desired colors.

Q5: Is on-site installation standardized? How is it done?

A: Yes, per BS 1722/EN 13241 standards: Lay posts at defined intervals, securely anchor with concrete or mechanical base. Mesh panels attached by anti-theft clamps or screws. Instructions and videos provided.

Q6: What factors most affect service life?

A: Coating thickness (>70 μm), zinc purity, mesh welding quality, and local environment (humidity, chemical exposure). Proper installation and routine cleaning extend durability.

Q7: How can I verify quality before shipment?

A: Customers can request live factory video inspection, SGS/BV/CE third-party reports, or random sample dispatch to labs. All panels labeled with traceable batch codes for transparency.

12. Related Products & Industry Comparison

- Sustainable Galvanized PVC Powder Coated 3D Welded Wire Panel Fence For Building Construction

- Galvanized Hog Wire Fence – ultimate for animal enclosures

- Gal Mesh Fence Panels for campus security & landscape integration

- Galvanized Wire Panels Fence for highways and industrial parks

- Galvanised Wire Mesh Sheets for DIY, fabrication, and architecture

Conclusion & Further Reading

Galvanised wire mesh panels remain the optimal solution for secure, sustainable, and visually appealing fencing in modern industries. With continual evolution towards better coatings, customizable manufacturing, and global compliance (ISO 1461, ASTM A974), they set new standards for performance and durability.

For in-depth discussions, technical updates, and industry best practices, visit leading forums and journals:

For in-depth discussions, technical updates, and industry best practices, visit leading forums and journals:

- Fencing Journal: Wire Mesh Trends 2024

- Steel Net Forum: Galvanised Mesh Panels & Fencing Section

- Sage Journals: Research Review on PVD/Galvanized Panel Perf. (2023)

Latest news

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025

Related Products