-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

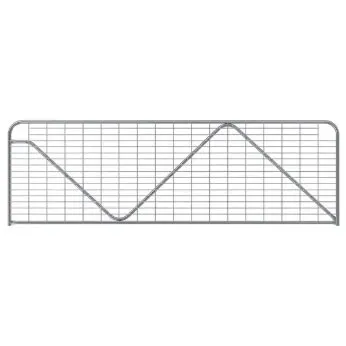

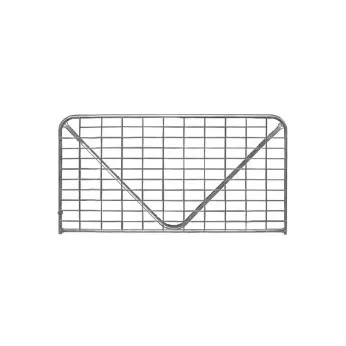

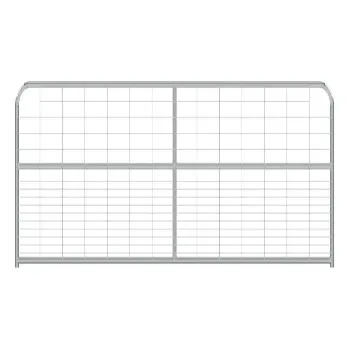

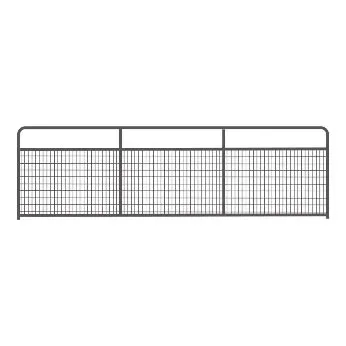

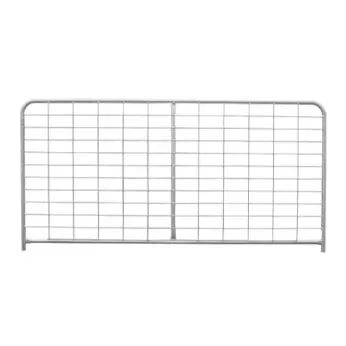

High Quality Galvanized Farm Gates with Smooth Edges—Safe?

Why Smooth-Edge Galvanized Farm Gates Are Becoming the Smart Buy

I’ve spent enough time in yards and paddocks to know a gate can make or break a day. When I first tested the High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection, the difference was obvious: no snags, no burrs, and animals stayed calm. It’s a small detail—smooth edges—but it prevents a lot of drama.

Industry trend, quick take

Farmers are upgrading to hot-dipped galvanized gates with embedded mesh—less vet work, fewer escape artists. To be honest, it’s also about total cost: fewer replacements over 10–20 years. Many customers say they’re done with thin, painted imports that rust before the second winter.

What stands out technically

- Heavy-duty steel frame, embedded mesh inside the frame (not just tacked on).

- Smooth, deburred edges for safe handling—nice when you’re moving ewes in a hurry.

- Hot-dip galvanizing for corrosion resistance; real-world life ≈ 12–20 years, climate depending.

- Designed for horses, cattle, sheep; suited to internal and boundary fence lines.

Core specifications (typical)

| Material | Q235/Q355 mild steel frame, embedded steel mesh |

| Finish | Hot-dip galvanized (≈70–100 μm zinc); optional powder over zinc |

| Common Heights | 1.2 m, 1.5 m (custom on request) |

| Widths | 8–16 ft typical; custom widths available |

| Edge Safety | Deburred, rounded corners, smooth welds |

| Testing | Salt spray ≥ 720 h (ASTM B117), weld shear/peel tests, gate deflection under load |

How it’s made (short version)

Materials cut and mitered → precision weld (low spatter, full-penetration joints) → mesh embedded inside the frame → shot-blast → edge deburring and rounding → hot-dip galvanizing per ISO 1461/ASTM A123 → QC: dimension, weld integrity, coating thickness → fitment check with hinges and latch. Service life varies by environment; coastal sites may see ≈12–15 years, inland can go 15–20+ with sensible maintenance.

Real-world applications

- Beef and dairy lanes, rotational grazing cells, boundary runs.

- Equestrian centers—less risk of skin abrasions around the head and chest.

- Sheep yards and drafting races; embedded mesh stops lambs slipping through.

- Municipal parks and wildlife holdings (surprisingly common).

Vendor snapshot (approximate)

| Vendor | Galvanizing | Edge Finish | Certs | Lead Time | Warranty |

|---|---|---|---|---|---|

| Shangping (PeilingTech) | Hot-dip, ISO 1461 | Deburred, rounded | ISO 9001; test reports | ≈ 15–30 days | Up to 3 years (site-dependent) |

| Local Fabricator | Varies (paint/HDG) | Varies | Shop-specific | 1–4 weeks | 1–2 years typical |

| Budget Import | Electro-galv. (thin) | Sharp spots reported | Limited | ≈ 30–60 days | 6–12 months |

Customization and options

Sizes, bar spacing, mesh gauge, hinge kits, chain/latch styles, and powder topcoat colors are all configurable. Origin: Room 818, Lijing INTL BLDG, No.681 Xinhua Road, Shijiazhuang, Hebei, China. If you need a tractor-friendly swing arc or narrow laneway spec, ask; in fact, most orders are tweaked a little.

Case notes from the field

- Midwest dairy (180 head): reported gate-related nicks down ≈ 70% after switching to High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection. No latch failures after one winter.

- Equestrian facility (22 stalls): staff liked the hand feel—no gloves needed for everyday moves; minor corrosion only at cut edges after 18 months, which is expected and manageable.

Standards, testing, and paperwork

Coating per ISO 1461/ASTM A123; mesh and weld checks to ISO 3834 principles; corrosion screened with ASTM B117 salt spray; mechanical checks include deflection under point load and hinge cycle tests (≥ 10k cycles target). Certifications supplied on request (ISO 9001, third-party test data).

Citations:

1) ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

2) ASTM A123/A123M: Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

3) ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

4) ISO 3834: Quality requirements for fusion welding of metallic materials.

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025