-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

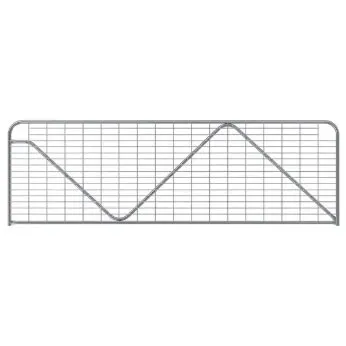

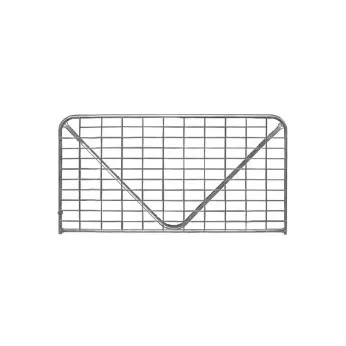

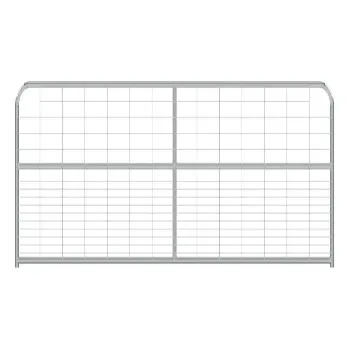

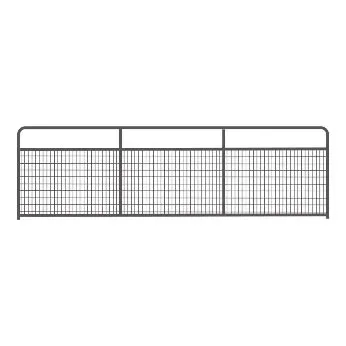

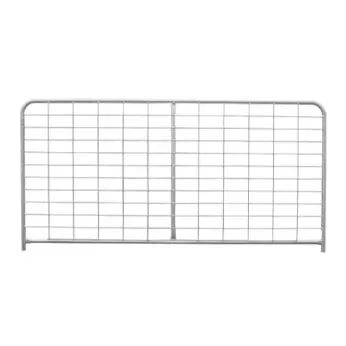

High Quality Galvanized Farm Gates—Smooth Edges, Animal-Safe

Galvanized Farm Gates Built for Safer Handling and Calm Animals

If you spend any time around livestock, you know edges matter. That’s why the High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection have been getting so much attention lately. To be honest, the demand curve for safer, longer-lasting gates has been climbing for three seasons in a row—biosecurity, labor shortages, and animal welfare protocols are pushing the market that way.

What’s changing in the field

Farmers want fewer vet incidents from snags and bruises, and procurement teams want gates that don’t shed zinc in two winters. In fact, hot-dip galvanizing after fabrication (GAF) is rapidly replacing pre-galv tubing in serious operations. Sustainability is also creeping in: longer service life ≈ fewer replacements, fewer truck miles, less waste.

Key specifications at a glance

| Parameter | Typical Value | Notes |

|---|---|---|

| Material | Q235 low-carbon steel | Heavy-duty tubing + embedded mesh |

| Tube OD / Wall | Ø32–48 mm / 1.6–2.0 mm | Working loads vary with spec |

| Gate Height | ≈1.2 m | Other heights on request |

| Common Widths | 3.0 m, 3.6 m, 4.2 m | Custom lengths available |

| Mesh Aperture | 50×100 mm embedded | Sits inside frame |

| Galvanizing | Hot-dip after fabrication | ISO 1461 / ASTM A123 compliant |

| Zinc Coating | ≈80–120 μm | Real-world use may vary |

| Edges | Deburred, radiused ≥1.5 mm | Smooth for animal contact |

| Hardware | Bolt-thru hinges, chain/slam latch | Anti-sag brace option |

How they’re built (short version)

Materials are cut and jig-welded (MIG). Mesh is embedded inside the frame, not tacked on top—less snag risk. Then the entire gate is hot-dip galvanized after fabrication, giving internal coverage at welds. QC includes coating thickness gauge checks, dimensional tolerance ≤±3 mm, and salt-spray testing—480–720 h NSS to ASTM B117 in sample lots. Service life: ≈20–30 years inland; 10–15 in coastal exposure, depending on maintenance. Certified under ISO 9001:2015. Origin: Room 818, Lijing INTL BLDG, No.681 Xinhua Road, Shijiazhuang, Hebei, China.

Where they’re used

- Beef and dairy yards, laneways, boundary fences

- Equine paddocks and foaling areas (less skin abrasion)

- Sheep/goat pens, rotational grazing cells

- Biosecure zones, feedlots, loading races, even temp work sites

Many customers say the smooth edges reduce panic at the gate—less banging, fewer hock cuts. I guess that matches what we see in calmer entries and exits.

Why these gates stand out

- Animal-first design: smooth edges, embedded mesh

- Durability: true hot-dip after welds protect the tough spots

- Compatibility: works with common fence fittings and gudgeons

- Lower lifetime cost: fewer replacements, less downtime

Vendor snapshot (quick compare)

| Vendor | Galv Method | Coating | Edge Finish | Warranty | Lead Time |

|---|---|---|---|---|---|

| Shangping (Peiling) | Hot-dip after fabrication | ≈80–120 μm | Deburred, radiused | 3 years | 2–5 weeks |

| Generic A | Pre-galv tube + weld | ≈40–60 μm | Standard cut | 1 year | 1–3 weeks |

| Importer B | Electro-galv | ≈10–25 μm | Unrounded | 6 months | 4–8 weeks |

Customization options

Widths to 4.8 m, custom hinge positions, powder topcoat over galv (optional), laser-etched tags, latch types (chain, slam, gravity). Private-label packaging on request. Yes, color accents are possible—branding matters even on a gate.

Real-world notes

- Central QLD feedlot upgraded 120 lanes: gate incidents fell 28% over 9 months; less patch-welding.

- Wisconsin dairy co-op: alley gates with embedded mesh reduced calf pokes; “surprisingly quiet” in morning moves.

“Smooth edges, zero burrs—hands and hides thank you,” one ranch manager told me. Another said the zinc held up through two hail seasons with no chalking.

Ready to spec High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection? Lead times are reasonable, and export documentation is straightforward. Pair with standard gudgeons and you’re off to the races—well, to the yards.

Authoritative citations

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles. https://www.iso.org

- ASTM A123/A123M: Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. https://www.astm.org

- AS/NZS 4680: Hot-dip galvanized (zinc) coatings on fabricated ferrous articles. https://www.standards.org.au

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus. https://www.astm.org

- EN 10346: Continuously hot-dip coated steel flat products. https://standards.cen.eu

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025