-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

Premium PVC Coated Wire Mesh for Sale | Durable & Weatherproof

Understanding PVC Coated Wire Mesh for Modern Industrial Applications

In the demanding landscape of modern infrastructure and security, the integrity and longevity of materials are paramount. Among the most versatile and robust solutions available is pvc coated wire mesh for sale. This specialized material offers an unparalleled combination of strength, corrosion resistance, and aesthetic adaptability, making it indispensable across a spectrum of B2B applications. From critical infrastructure protection to advanced animal containment systems like the Animal Barrier Metal Hot Dip Galvanized Dog Wire Welded Mesh, its utility is broad and impactful. This comprehensive guide delves into the technical intricacies, market dynamics, and strategic advantages of this essential product, catering to the needs of procurement professionals, engineers, and project managers.

The demand for durable and low-maintenance fencing and barrier solutions continues to grow, driving innovation among pvc coated wire mesh manufacturers. Our focus is to provide an in-depth understanding of the product, ensuring that stakeholders can make informed decisions when sourcing these critical components for their projects.

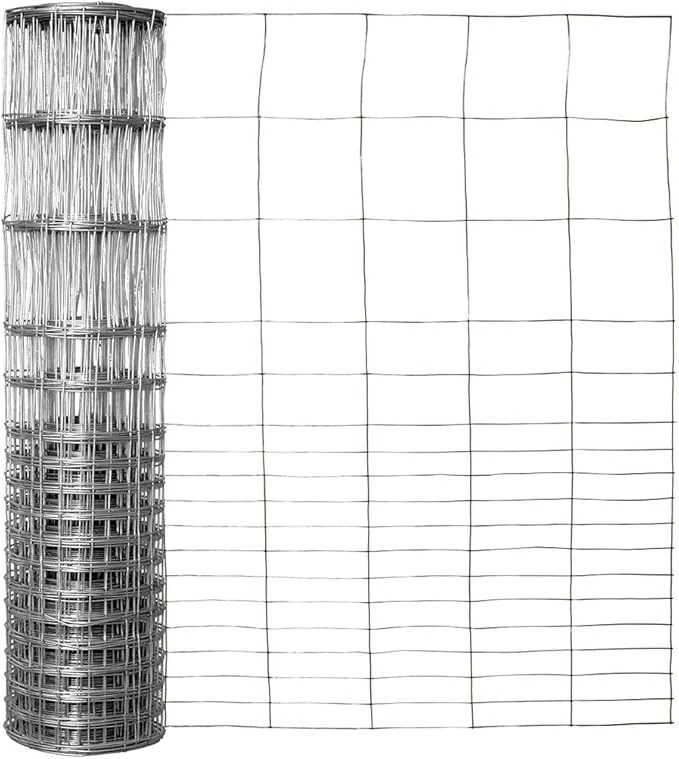

Figure 1: Typical PVC Coated Welded Wire Mesh Application

Detailed Manufacturing Process Flow of PVC Coated Wire Mesh

The production of pvc coated wire mesh for sale is a multi-stage, precision-engineered process designed to impart superior strength and weather resistance. The integrity of the final product hinges on meticulous execution at each phase, ensuring compliance with international standards such as ISO 9001 for quality management and relevant ASTM or ANSI specifications for material performance.

Key Stages:

- Wire Drawing and Annealing: High-carbon steel rods are drawn through dies to achieve the desired wire gauge. This process increases tensile strength. Subsequent annealing heat treatment reduces hardness and improves ductility, making the wire pliable for welding without compromising strength. Typical materials used are low-carbon steel wires (e.g., Q195, SAE1008).

- Welding of Wire Mesh: Precision welding machines fuse the horizontal and vertical wires at their intersections, creating a rigid mesh structure. For pvc coated welded wire mesh manufacturers, this step is critical for dimensional stability and structural integrity. Welding methods typically involve resistance spot welding, ensuring strong, uniform bonds.

- Hot-Dip Galvanization (Optional but Recommended): After welding, the mesh is immersed in a bath of molten zinc (450-460°C). This creates a metallurgical bond, forming a protective zinc layer that offers sacrificial corrosion protection, significantly extending the service life. This step is crucial for products like Animal Barrier Metal Hot Dip Galvanized Dog Wire Welded Mesh, where environmental exposure is constant. Typical zinc coating weights range from 40-300 g/m², meeting ASTM A123 standards.

- Pre-treatment for PVC Coating: The galvanized mesh undergoes thorough cleaning, degreasing, and phosphating. This prepares the surface for optimal adhesion of the PVC layer, preventing delamination and ensuring a uniform coat.

- PVC Coating Application: The mesh is then coated with PVC (Polyvinyl Chloride) through a fluidised bed or spray coating process. In the fluidised bed method, the preheated mesh is dipped into a bed of finely powdered PVC, which melts and adheres to the surface. For spray coating, liquid PVC is electrostatically applied. The mesh is then cured in an oven, forming a strong, durable, and weather-resistant polymer layer. This PVC layer typically ranges from 0.4mm to 1.2mm in thickness, providing exceptional protection against UV radiation, chemicals, and physical abrasion.

- Cooling and Quality Control: After curing, the mesh is cooled and subjected to stringent quality control checks. This includes visual inspection for uniform coating, adhesion tests (e.g., cross-hatch test), coating thickness measurements, and dimensional accuracy checks (mesh aperture, panel size).

- Packaging: Finished rolls or panels are carefully packaged to prevent damage during transit, ensuring they arrive in optimal condition for deployment.

This meticulous process ensures the longevity and high performance of pvc coated wire mesh across various demanding environments. The dual protection of galvanization and PVC significantly extends service life, often exceeding 15-20 years even in harsh coastal or industrial atmospheres, demonstrating remarkable corrosion resistance and minimal maintenance requirements.

Industry Trends and Market Dynamics

The market for pvc coated wire mesh for sale is experiencing robust growth, driven by increasing urbanization, infrastructure development, and a heightened focus on security and environmental protection. Industry reports indicate a compound annual growth rate (CAGR) of approximately 4-6% for the global wire mesh market, with PVC-coated variants commanding a significant share due to their superior performance characteristics over uncoated or merely galvanized alternatives.

- Sustainability Focus: While PVC traditionally faces environmental scrutiny, advancements in PVC formulation and recycling technologies are leading to more sustainable products. Many pvc coated wire mesh manufacturers are now offering phthalate-free and lead-free PVC options, aligning with global environmental regulations and corporate social responsibility initiatives.

- Customization Demand: There's a growing trend towards highly customized solutions, not just in mesh size and wire gauge, but also in specific PVC colors (e.g., green pvc coated welded wire mesh for landscaping integration) and specialized coatings for extreme UV exposure or chemical resistance.

- Smart Fencing Integration: The integration of wire mesh fencing with smart technologies, such as perimeter intrusion detection systems (PIDS) and CCTV, is becoming more prevalent, particularly in high-security applications like airports, data centers, and critical infrastructure.

- Global Supply Chain Optimization: Geopolitical shifts and raw material price volatility are pushing buyers to seek reliable pvc coated welded wire mesh suppliers with diversified supply chains and robust quality control systems.

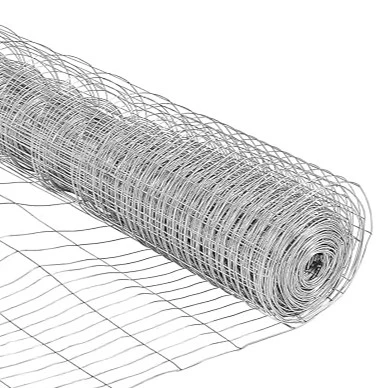

Figure 2: Customization in PVC Coated Wire Mesh for Varied Aesthetics

Technical Specifications and Performance Metrics

Selecting the appropriate pvc coated wire mesh for sale requires a deep understanding of its technical parameters. These specifications directly impact the mesh's suitability for specific applications, its durability, and its long-term cost-effectiveness. Key parameters include wire gauge, mesh aperture, PVC coating thickness, and material composition.

Typical Product Specification Table:

These specifications are crucial for engineering precise solutions, ensuring the pvc coated wire mesh for sale meets the stringent demands of its intended application, from petrochemical installations requiring high chemical resistance to water supply and drainage systems needing robust anti-corrosion properties.

Application Scenarios and Industry Benefits

The versatility of pvc coated wire mesh makes it a preferred material across diverse industries. Its unique properties provide significant advantages in scenarios where durability, aesthetic appeal, and minimal maintenance are critical.

Target Industries and Typical Uses:

- Petrochemical and Chemical Plants: Used for safety enclosures, equipment guards, and perimeter fencing. Its high corrosion resistance, especially to chemical splashes and fumes, ensures long service life in aggressive environments, reducing the frequency of replacement and associated downtime.

- Metallurgy and Mining: Applications include screening, sifting, and protective barriers around heavy machinery. The PVC coating enhances wear resistance and prevents spark generation from metallic friction, contributing to operational safety.

- Water Supply & Drainage Systems: Employed in filtration systems, sewage treatment plants, and embankment stabilization. The excellent resistance to water, moisture, and mild chemicals (like those in treated water) makes it ideal for long-term use in wet conditions, preventing rust and degradation.

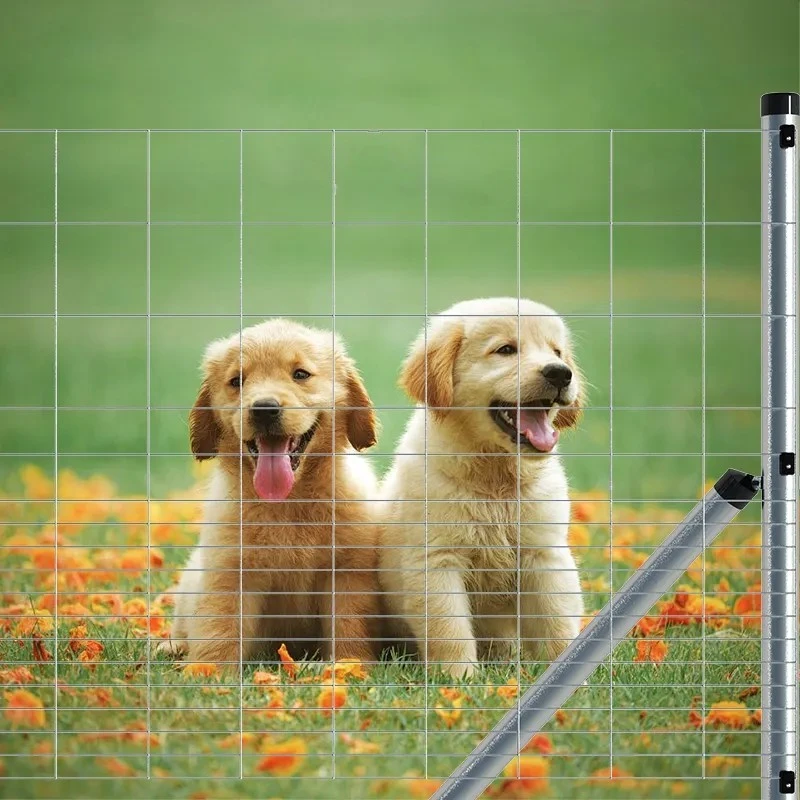

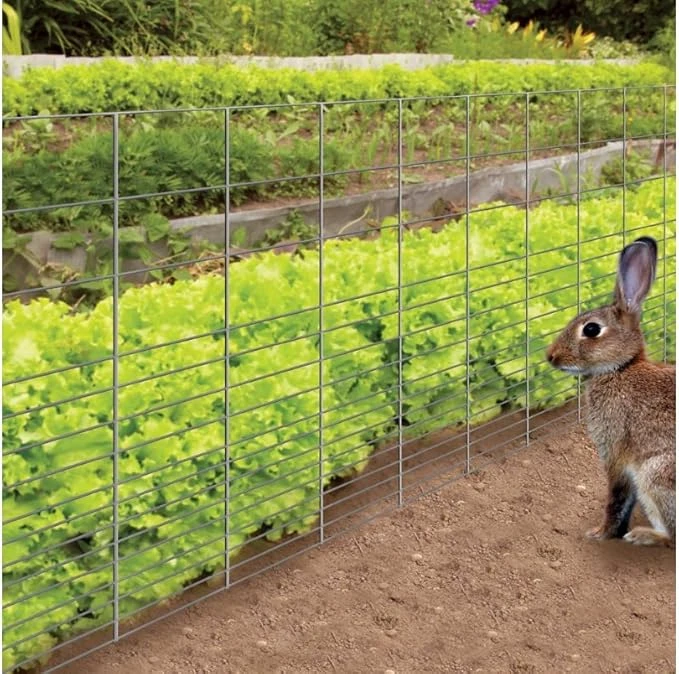

- Agriculture and Animal Husbandry: Critical for animal enclosures, poultry cages, and farm fencing. Products like the Animal Barrier Metal Hot Dip Galvanized Dog Wire Welded Mesh exemplify its use in creating safe, durable, and escape-proof habitats, benefiting from its non-toxic PVC coating and strong welded joints.

- Construction and Infrastructure: Utilized for temporary fencing, safety barriers on construction sites, and gabion baskets for erosion control. The aesthetic options, particularly green pvc coated welded wire mesh, allow for seamless integration into natural landscapes.

- Residential and Commercial Security: High-security fencing for properties, schools, and parks. The robust construction deters intruders, while the PVC coating minimizes sharp edges, enhancing safety.

Technical Advantages in Application:

- Superior Corrosion Resistance: The combined hot-dip galvanization and PVC coating offer dual-layer protection against rust, acids, alkalis, and saline environments. This extends service life significantly, especially in harsh outdoor or industrial settings.

- Enhanced Durability and Impact Resistance: The PVC layer provides a cushioning effect, absorbing minor impacts and reducing wear and tear on the underlying steel. It also protects against UV degradation, preventing cracking and fading over time.

- Low Maintenance: Due to its excellent resistance properties, PVC coated mesh requires minimal upkeep, leading to significant cost savings over its lifespan. Cleaning is typically simple, requiring only water and mild detergents.

- Aesthetic Versatility: Available in a wide range of colors, PVC coated mesh can be seamlessly integrated into various architectural and landscape designs, enhancing visual appeal without compromising functionality.

- Safety and Comfort: The smooth PVC coating eliminates sharp edges, making the mesh safer to handle during installation and reducing the risk of injury to humans or animals once installed. This is a critical feature for products designed for animal containment.

Figure 3: PVC Coated Mesh in Animal Containment

Vendor Comparison and Customized Solutions

When sourcing pvc coated wire mesh for sale, evaluating potential pvc coated welded wire mesh suppliers goes beyond mere price comparison. Factors such as manufacturing capabilities, adherence to international standards, customization flexibility, and after-sales support are paramount.

Key Differentiators for Suppliers:

Customized Solutions:

Leading pvc coated welded wire mesh factory operations understand that off-the-shelf solutions don't always meet the unique challenges of complex industrial projects. Customization capabilities are a hallmark of a proficient pvc coated welded wire mesh supplier. This includes:

- Bespoke Dimensions: Tailoring mesh panel sizes, roll lengths, and widths to minimize waste and optimize installation efficiency for specific site layouts.

- Specialized Wire Gauges and Mesh Apertures: Adjusting wire thickness and opening size to meet specific load-bearing requirements, security levels, or filtration needs.

- Color Matching: Providing PVC coatings in custom RAL colors for architectural integration, branding, or specific environmental camouflage (e.g., green pvc coated welded wire mesh for parks).

- Advanced Coating Formulations: Offering PVC variants with enhanced properties such as extreme UV resistance for equatorial regions, anti-microbial additives for hygiene-critical environments, or flame-retardant properties for fire-sensitive areas.

- Integrated Solutions: Supplying mesh with pre-fabricated components like gates, posts, and specialized mounting hardware, ensuring a complete system solution.

Figure 4: The Versatility of Custom PVC Coated Wire Mesh

Application Case Studies and Customer Experience

Real-world deployments demonstrate the tangible benefits and reliability of pvc coated wire mesh for sale. These case studies highlight not only the product's performance but also the value added by experienced pvc coated welded wire mesh manufacturers.

Case Study 1: Coastal Infrastructure Protection

- Client: Major Port Authority, Southeast Asia.

- Challenge: Required durable perimeter fencing for cargo storage areas exposed to extreme saline environments, high humidity, and strong winds. Previous galvanized-only fencing had a service life of only 5-7 years due to rapid corrosion.

- Solution: Supplied 5,000 linear meters of heavy-duty pvc coated welded wire mesh (4mm wire, 50x50mm aperture, 1.0mm PVC coating over hot-dip galvanization) in a dark blue finish to match corporate branding.

- Outcome: After 8 years, the mesh showed minimal signs of degradation, with no rust visible and PVC coating intact. The client reported significant savings in maintenance and replacement costs, projecting a total service life exceeding 20 years. The superior corrosion resistance was key to this success.

- Customer Feedback: "The quality of the PVC coated mesh provided by our supplier exceeded expectations. Its longevity in our challenging coastal environment has been exceptional, significantly reducing our operational expenditure on fencing maintenance."

Case Study 2: Wildlife Containment for a Conservation Park

- Client: National Wildlife Conservation Park, Europe.

- Challenge: Needed secure, animal-friendly fencing for various enclosures, including those for canine species, requiring mesh that was strong enough to prevent escapes, soft enough to prevent injury, and aesthetically pleasing to blend into natural surroundings.

- Solution: Provided a customized solution of green pvc coated welded wire mesh (3.5mm wire, 25x50mm aperture), specifically designed as an "Animal Barrier Metal Hot Dip Galvanized Dog Wire Welded Mesh" equivalent, with a thicker PVC coating for added cushioning and a nature-friendly color.

- Outcome: The mesh was successfully installed across multiple enclosures, providing robust containment with a reduced risk of animal injury due to the smooth PVC. The green color blended seamlessly, enhancing the park's natural aesthetic. The park lauded the mesh's longevity and minimal impact on the animals.

- Customer Feedback: "Our search for an effective and humane animal barrier led us to the PVC coated mesh. Its strength and non-abrasive surface have proven ideal for our wildlife, and the aesthetic integration is perfect for our park visitors."

Figure 5: Longevity and Performance in Diverse Environments

Trustworthiness: FAQ, Lead Time, Warranty & Support

Trust is foundational in B2B partnerships. We strive to provide complete transparency regarding our products, processes, and support infrastructure, ensuring you feel confident in choosing us as your pvc coated wire mesh supplier.

Frequently Asked Questions (FAQ):

Q: What is the typical service life of your PVC coated wire mesh?

A: With our double protection system (hot-dip galvanization + PVC coating), our mesh typically has a service life of 15-20 years, even in challenging outdoor environments. This can vary slightly based on specific environmental conditions and maintenance practices.

Q: Is the PVC coating environmentally friendly?

A: We prioritize sustainability. Our PVC coating formulations are lead-free and phthalate-free, complying with modern environmental regulations. We can also offer PVC that contains recycled content upon request.

Q: Can your pvc coated wire mesh withstand extreme temperatures?

A: Our mesh is designed to perform effectively in a wide range of temperatures, typically from -30°C to +70°C, without significant degradation of the PVC coating or core wire properties. For applications outside this range, specialized coatings can be discussed.

Q: What are the key differences between a standard galvanized mesh and your PVC coated mesh?

A: While galvanized mesh offers good corrosion resistance, adding a PVC coating provides an additional layer of protection against physical abrasion, UV radiation, chemical exposure, and greatly enhances aesthetic appeal. This dual protection significantly extends lifespan and reduces maintenance.

Lead Time & Fulfillment Details:

Our streamlined manufacturing processes and robust supply chain enable efficient order fulfillment.

- Standard Orders: For common specifications of pvc coated wire mesh for sale, our typical lead time from order confirmation to dispatch is 3-6 weeks, depending on order volume and current production schedule.

- Customized Orders: For bespoke mesh specifications, colors, or special coatings, lead times typically range from 6-10 weeks, allowing for material sourcing and specific production line adjustments.

- Shipping & Logistics: We collaborate with trusted global logistics partners to ensure timely and secure delivery to your specified location, whether by sea, air, or land freight. Detailed shipping estimates are provided with each quotation.

Warranty Commitments:

We stand by the quality of our products. All our pvc coated wire mesh comes with a comprehensive limited warranty against manufacturing defects and premature degradation under normal use and recommended installation.

- Standard Warranty: A 10-year limited warranty covers material integrity and coating adhesion for outdoor applications.

- Extended Warranty: Options for extended warranties are available for specific projects, subject to terms and conditions.

- Coverage: Our warranty covers defects in materials and workmanship, ensuring that the mesh performs as per its technical specifications when installed correctly.

Customer Support Information:

Our commitment to our clients extends beyond delivery. Our dedicated support team is available to assist you.

- Technical Assistance: Our engineers provide expert guidance on product selection, installation best practices, and troubleshooting.

- Sales Inquiries: Contact our sales team for quotations, product information, and order placement.

- After-Sales Service: For any post-purchase support, warranty claims, or feedback, our customer service department is ready to help.

- Contact: Please visit our website or use the contact details provided in your order documentation.

Conclusion

The demand for robust, reliable, and aesthetically adaptable perimeter solutions continues to escalate. PVC coated wire mesh for sale stands as a premier choice for B2B applications, delivering unmatched durability, superior corrosion resistance, and versatile aesthetic integration. As a leading pvc coated welded wire mesh manufacturer and pvc coated welded wire mesh factory, we are committed to engineering excellence, providing customized solutions that meet the precise requirements of diverse industrial projects. Our rigorous manufacturing processes, adherence to international standards, and comprehensive customer support ensure that you receive a product that not only performs but also provides long-term value and peace of mind.

References

- ASTM International. (n.d.). _ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products_. Retrieved from astm.org

- International Organization for Standardization. (n.d.). _ISO 9001:2015 Quality management systems – Requirements_. Retrieved from iso.org

- European Committee for Standardization. (n.d.). _EN ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles - Specifications and test methods_. Retrieved from cencenelec.eu

- The Wire Association International. (n.d.). _Wire and Cable Industry Resources_. Retrieved from wirenet.org

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025