-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

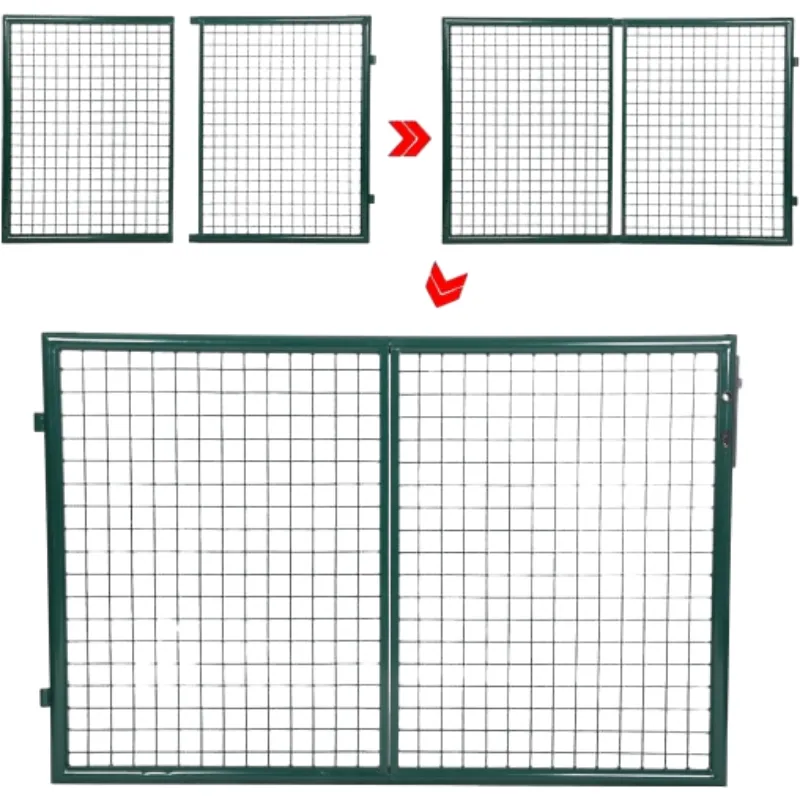

Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door

Hands-on Review: Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door

If you’ve walked a modern estate, school perimeter, or a tidy logistics yard lately, you’ve seen the shift: clean, mesh-look gates replacing heavy, opaque slabs. To be honest, it’s practical minimalism. The Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door from PeiLing leans right into that trend—security you can see through, without the visual bulk. I visited their Hebei facility a while back; the obsession with coating quality was obvious (good sign when you’re buying for outdoors).

Quick spec sheet (real-world values may vary)

| Product | Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door |

| Origin | Room 818, Lijing INTL BLDG, No.681 Xinhua Road, Shijiazhuang, Hebei, China |

| Material | Hot-dip galvanized steel (ISO 1461) or stainless steel option; powder-coated polyester |

| Finish | Outdoor polyester powder, UV-resistant (TGIC-free options) |

| Wing type | Double swing with splice-plate reinforcement |

| Coating build | Zinc layer ≈ 70–120 μm; powder ≈ 60–90 μm |

| Mesh aperture | Commonly 50×200 mm (custom on request) |

| Hinges/Lock | Adjustable hinges; euro-profile cylinder or padlock hasp |

| Service life | ≈ 10–20 years coastal; 15–25 years inland, with routine care |

What’s driving the trend

Municipal and residential buyers want visibility (CPTED thinking), less maintenance, and clean lines. Double-wing formats handle vans and service trucks, while the round-pipe frame resists torsion when people lean, push, or—let’s be frank—try to climb.

How it’s built — process flow

- Materials: Q235/Q355 steel tubes and infill mesh; stainless option for aggressive sites.

- Cutting & forming: CNC saw + jig welding (MIG), splice-plate alignment to keep wings square.

- Galvanizing: hot-dip per ISO 1461; drain holes placed to avoid trapped flux.

- Pretreatment: degrease, rinse, phosphate; powder coat (polyester) and oven cure.

- QC tests: adhesion ASTM D3359 ≥ 4B–5B; impact ASTM D2794 ≈ 2.5–4.0 J; salt spray ISO 9227 ≈ 720–1000 h; UV ASTM G154 cycles for gloss/color hold.

- Fit-out: adjustable hinges, latch set, strike plate; final swing/clearance inspection.

Where it fits best

- Residential driveways and garden perimeters (lockable, pet-friendly).

- Schools and parks—good visibility for supervision.

- Light industrial and logistics entrances; utility yards; farm lanes.

Vendor comparison (indicative)

| Factor | PeiLing | Generic Importer A | Local Fabricator B |

| Lead time | ≈ 20–35 days | ≈ 35–60 days | ≈ 10–25 days |

| Coating system | HDG + powder, documented | Paint or thin powder | Varies; often paint only |

| QC & tests | Adhesion/impact/spray data | Limited paperwork | On request; mixed |

| Warranty | Up to 5–10 yrs (site-dependent) | 1–3 yrs | Varies |

Customization options

Heights, wing widths, locksets, automation-ready plates, RAL colors, tighter mesh for anti-climb, privacy slats, even stainless hardware. Many customers say the adjustable hinges save time on slightly uneven posts—small thing, big deal during install.

Field notes (quick case studies)

Riverside HOA: 4 m opening, double wing, RAL 6005. After two summers, color drift was negligible; the committee liked the “see-through security.”

Light industrial depot: Forklift traffic demanded stiffness; the splice-plate joint held alignment after repeated impacts from careless pallet jacks (not recommended, but it happens).

Compliance & testing snapshots

- Galvanizing: ISO 1461 guidance; coating thickness logged by micrometer checks.

- Corrosion: ISO 9227 salt spray ≈ 720–1000 h target before red rust (edge creep excluded).

- Adhesion: ASTM D3359; Impact: ASTM D2794; UV/weathering: ASTM G154 cycles.

- Gates and automation: selection may reference EN 13241 (where applicable); powder complies with REACH/RoHS statements from paint suppliers.

Bottom line: the Round Pipe Splice Plate Double Wing Entrance Mesh Metal Door hits that sweet spot—durable, tidy, and sensibly engineered. If you’re speccing for a coastal site, ask for upgraded zinc and a seawater-grade topcoat. Inland? You’ll likely get decades with routine care.

Authoritative citations

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025