-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

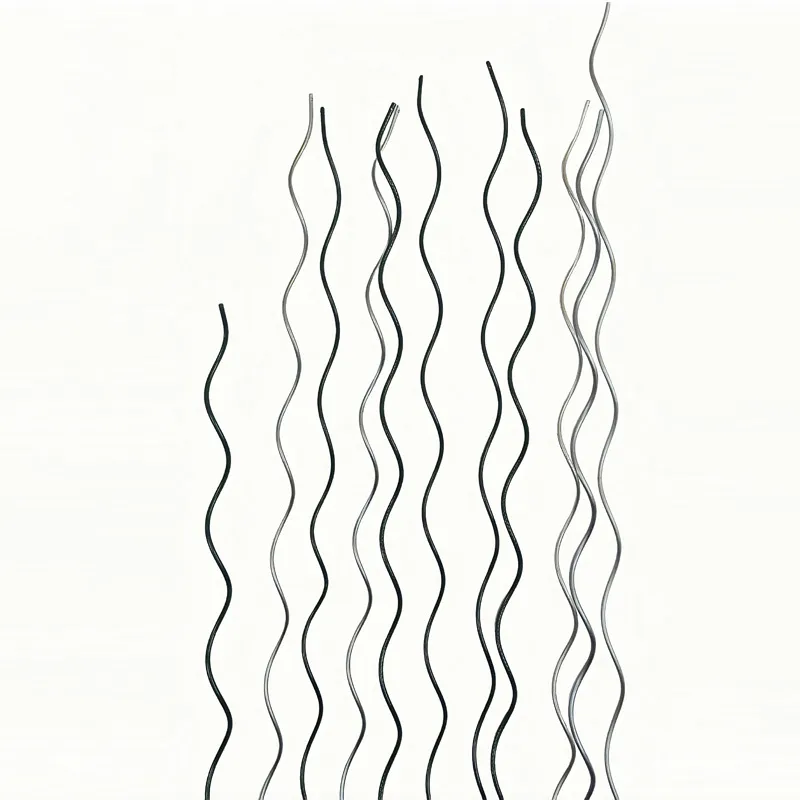

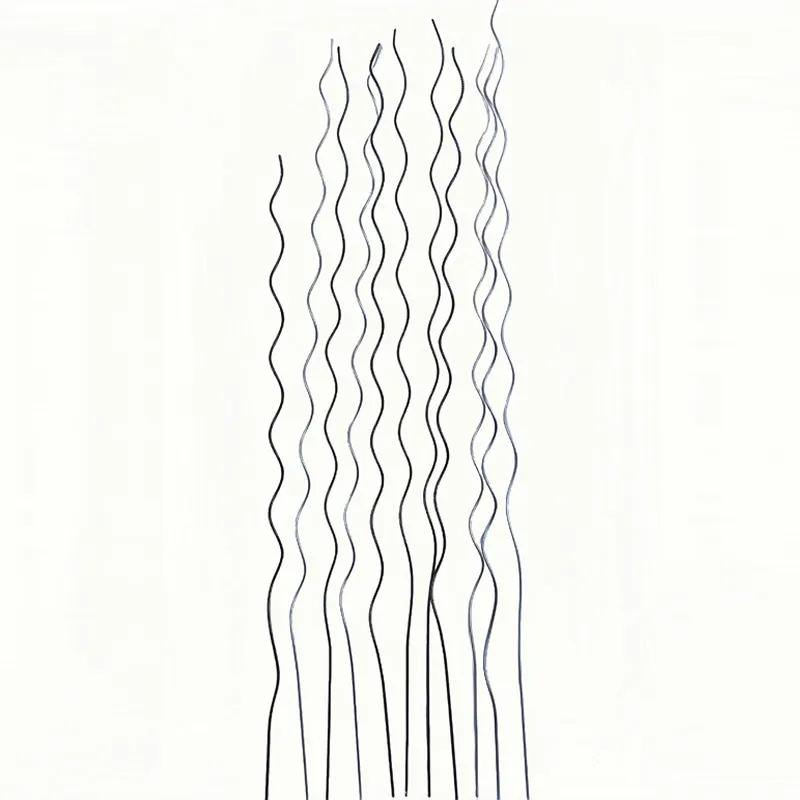

Spiral Tomato Stakes – Rustproof, No-Tie, Space-Saving

A Field-Tested Look at Spiral Tomato Stakes for Growers Who Need Results

In the last few seasons I’ve watched commercial and backyard growers quietly switch from cages and bamboo to Spiral Tomato Stakes. Not because they’re trendy, but because they shave minutes off training, don’t tangle, and—surprisingly—survive more seasons than folks expect. The model I’ve been following is the Galvanized PVC Powder Coated Tomato Spiral Plant Support, 7 mm × 1.8 m. It’s a mouthful, but the spec sheet is legit.

Industry trend, briefly

Tomato support is trending toward coated steel with anti-corrosion layers, lighter labor per plant, and modular packaging. Growers care about lifecycle cost per season, not the sticker price. Coated Spiral Tomato Stakes hit that sweet spot: set-and-forget, easy to sanitize, and stackable for off-season storage.

Product snapshot and specs

Material is heavy-duty steel wire (galvanized), then PVC powder coated. Options: 6/7/8 mm wire; lengths 1.0–2.2 m. Colors: rich black, white, or custom. To be honest, 7 mm × 1.8 m is the workhorse for indeterminates in tunnels.

| Parameter | Spec (≈ real-world) |

| Wire diameter | 6 / 7 / 8 mm (7 mm common) |

| Length options | 1.0 / 1.5 / 1.8 / 2.0 / 2.2 m |

| Coating system | Galvanized base + PVC powder coat (≈120–160 μm total) |

| Corrosion resistance | Salt spray 480–720 h (ISO 9227 lab data, conditions vary) |

| Load capacity | ≈18–25 kg vertical before yield (7–8 mm) |

| Packaging | 10 or 25 pcs/bundle, film wrapped, carton or wooden crate |

How they’re made (quick process flow)

- Material: low-carbon steel wire to ASTM A641/A641M (galvanized).

- Forming: straightening + spiral bending; tip “screw” form 7 or 8 turn pattern.

- Surface prep: degrease, phosphate, oven-dry.

- Coating: PVC powder electrostatic spray; oven cure for adhesion.

- Testing: adhesion cross-hatch (ISO 2409), salt spray (ISO 9227), bend test at -10°C.

- Service life: ≈5–8 seasons typical; arid climates often longer.

Where they shine

Open fields, high tunnels, greenhouses, and—yes—balcony buckets. Mounting tip: bury the spiral before planting to avoid root damage; 25–30 cm embed is plenty for 1.8 m. Training is tool-free: just wind the vine. Many customers say pruning is faster because leaves aren’t snagging on a cage grid.

Vendor snapshot (what I’m seeing on the market)

| Vendor | Material/Coating | Testing | Lead time | Lifecycle cost ≈ |

| Peilingtech (origin: Room 818, Lijing INTL BLDG, No.681 Xinhua Road, Shijiazhuang, Hebei, China) | Galv. steel + PVC powder | ISO 9227, ISO 2409; RoHS/REACH statements | ≈15–25 days | Low (5–8 seasons) |

| Generic Importer A | Plain galvanized | Basic QC only | ≈30–40 days | Medium (2–4 seasons) |

| Private Label B | Painted steel | Unknown | Stock dependent | Medium–High |

Real-world notes

- Case 1: 2,400 pcs in a Midwest tunnel—reported 18% faster trellising vs. cages, zero coating chips after one winter stack.

- Case 2: UK polytunnel grower—8 mm × 2.0 m handled heavy heirlooms; salt air exposure acceptable after 2 seasons.

- Feedback: “Black coating hides scuffs, rinses clean at end of season.” Another grower liked custom white for branding—fair point.

Compliance, customization, and odds-and-ends

Certs and declarations commonly available: ISO 9001 factory QA, RoHS/REACH coating compliance, and material conformity to ASTM A641. Custom options: wire gauge, length, color, retail packs, barcode, and logo on cartons. For shipping, bundles of 10 or 25 minimize warehouse chaos.

Mounting reminder: bury spiral before planting to safeguard roots; rotate the vine into the helix as it grows. Off-season: stack flat, avoid sharp impacts to preserve the coating.

Bottom line

If you’re scaling up or just sick of wobbly cages, coated steel Spiral Tomato Stakes are the pragmatic choice. They’re dull in the best way possible: durable, predictable, easy to live with.

Authoritative references

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025