-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

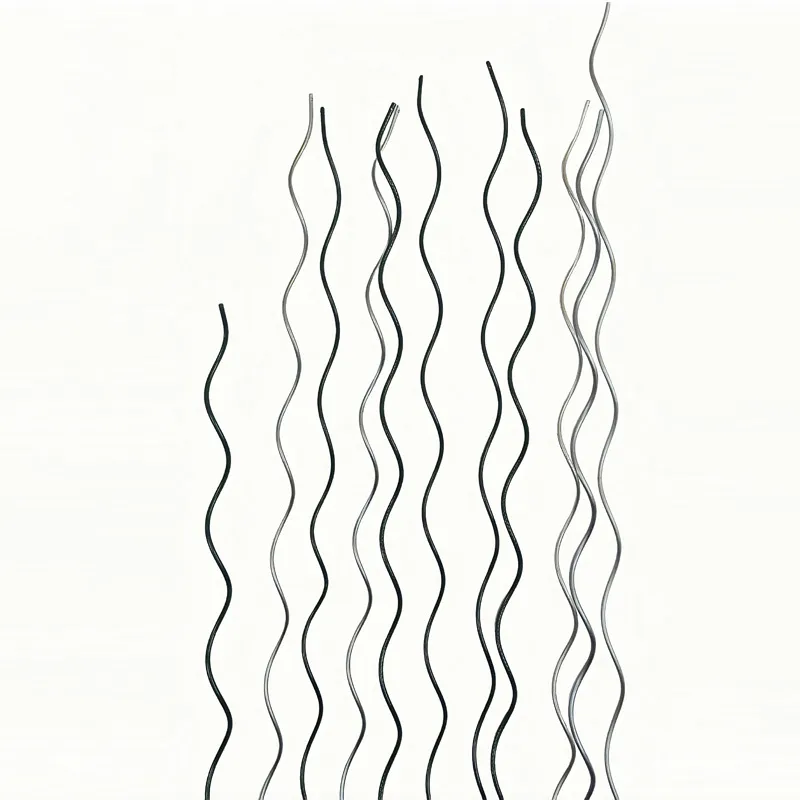

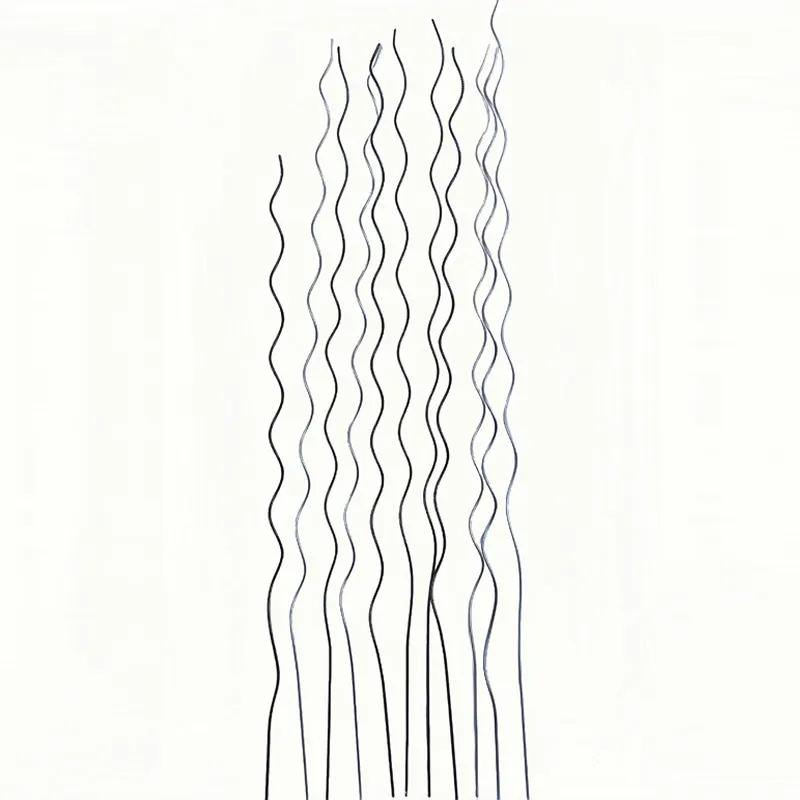

Spiral Tomato Stakes - Rustproof, Tie-Free, Space-Saving

Field Notes on Tomato Support: What I’ve Learned About Spiral Stakes

If you’re shopping for spiral tomato stakes, you’ve probably noticed how wildly quality and finish can vary. I’ve toured a few factories, heard growers grumble (and praise), and—frankly—snapped my share of budget stakes. The model that keeps popping up among market growers is the Galvanized PVC Powder Coated Tomato Spiral Plant Support 7mm×1.8m from PeilingTech, based out of Room 818, Lijing INTL BLDG, No.681 Xinhua Road, Shijiazhuang, Hebei, China.

What’s driving demand right now

Two big trends: urban gardeners want cleaner-looking plots without cages everywhere, and commercial tunnels need high-density support that doesn’t snag twine during pruning. The helical design of spiral tomato stakes lets you guide stems as they climb—no clips, minimal tying. That’s time saved, which is the real currency in a 12-week harvest run.

Key specifications (real-world notes included)

| Product Name | Galvanized PVC Powder Coated Tomato Spiral Plant Support 7mm×1.8m |

| Material | Heavy-duty carbon steel wire (low carbon, draw-strength optimized) |

| Wire Diameter | 6, 7, 8 mm optional (7 mm popular for field + tunnel) |

| Lengths | 1.0, 1.5, 1.8, 2.0, 2.2 m |

| Process | Precision bending (helix), deburring, galvanizing, then powder or PVC coat |

| Surface | Powder coated (≈60–90 μm) or PVC coated (≈300–500 μm), real-world may vary |

| Color | Rich black, white, or customized RAL |

| Spiral “Screw” | 7 or 8 turns (approx), optimized for vine support |

| Package | 10 or 25 pcs/pack with film bulk, carton or wooden crate |

How they’re made (and tested)

- Materials: low-carbon steel wire drawn to 6–8 mm; zinc-coated per ASTM A641 class options.

- Forming: CNC bending yields consistent helix; ends are tapered for ground entry.

- Coating: powder epoxy-polyester or PVC over zinc for corrosion resistance.

- Testing: salt spray ISO 9227 (typical ≥240 h no red rust, coating-dependent); bend/flex cycles ≈500; pull-out in loam ≈180–250 N (site-dependent).

- Service life: field feedback suggests 5–10 seasons if stored dry; coastal climates shorten that.

Where they work best

Backyard plots, high tunnels, balcony planters, and CSA fields. Install tip: bury the stake before transplanting to protect roots—yes, that small step matters. For indeterminates, guide stems around the helix weekly; for determinate varieties, I use spiral tomato stakes as tidy mid-height support, reducing flare-outs in windy spells.

Vendor comparison (my take)

| Criteria | PeilingTech | Big-Box Generic | Low-Cost Import |

|---|---|---|---|

| Wire options | 6/7/8 mm | Usually 5–6 mm | 5–7 mm (varies) |

| Coating | Zinc + Powder/PVC | Painted only | Mixed; spec unclear |

| Lead time | ≈15–30 days | In stock seasonal | ≈25–45 days |

| Certs | ISO 9001; RoHS/REACH coating claims | N/A on pack | Varies |

| Customization | Color, length, wire dia, branding | Limited | Possible, spec risk |

Real grower notes (short and sweet)

- “Didn’t peel after two summers—PVC held up.”

- “7 mm is the sweet spot; 8 mm is a tank but overkill for patio pots.”

- “Salt air farm: powder coat + zinc was fine after one season; we’ll see by year three.”

Use, care, and buying tips

Push 25–30 cm into soil before planting; rotate stems around the helix as they grow. Hose off sap, dry before storage. For windy sites, I pair spiral tomato stakes with a low cross-tie. Bulk orders ship 10 or 25 per pack with film, then carton or crate. Custom RAL colors look sharp in retail sets, by the way.

Compliance and standards

Look for zinc-coated wire per ASTM A641, corrosion checks via ISO 9227 salt spray, and factory QA under ISO 9001. Agronomy guidance on staking density from university extensions is still gold—worth a read before spacing rows.

Quick case study

A 2-acre tunnel grower switched 600 plants to 7 mm, 1.8 m stakes. Labor on tying dropped roughly 20%, damage during pruning fell noticeably (fewer snags than cages). Yield was flat—good!—but pack-out cleanliness improved because fruit stayed off the lane.

- ASTM A641/A641M – Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire.

- ISO 9227:2017 – Corrosion tests in artificial atmospheres – Salt spray tests.

- UF/IFAS Extension – Staking/Training Tomatoes for Production (accessed 2025).

- Royal Horticultural Society – How to train and support tomatoes (accessed 2025).

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025