-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

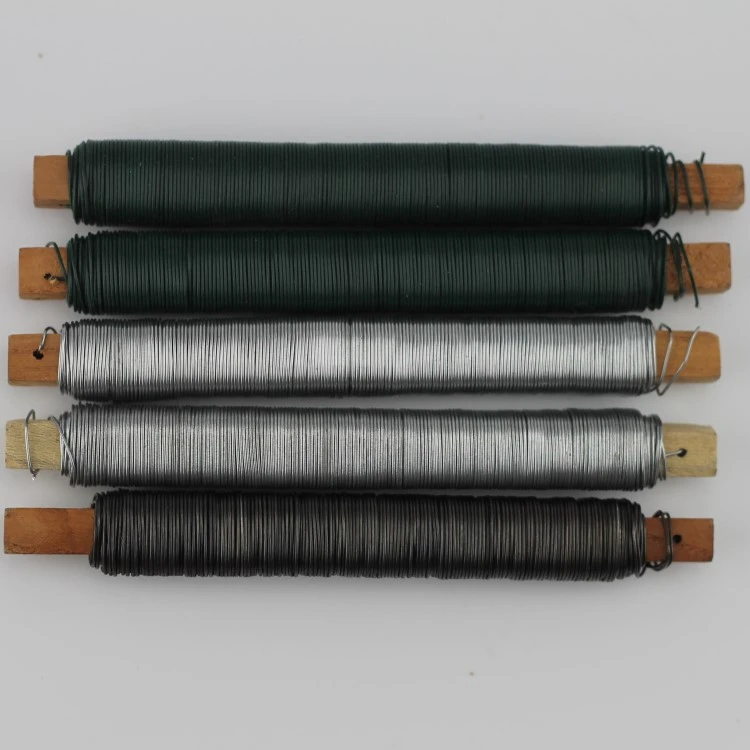

Supply High Quality PVC Coated Silver Wire - Rustproof

PVC-Coated “Silver” Wire Buyers Guide: Real-World Specs, Trends, and What Matters Now

If you’re sourcing Supply High Quality PVC Coated Silver Wire in 2025, you’ve probably noticed the market quietly shifting. Buyers want better adhesion, tighter tolerances, cleaner spooling—yet still expect fast lead times and friendly MOQs. The product is also known as painted wire, floral wire, or “Wooden Stick Wire” in crafts; same idea, different jargon. And yes—“silver” here usually means the color, not precious metal (I get asked that a lot).

What’s Driving Demand

- Crafts and décor: stable colors, smooth finish for weaving and bookbinding.

- Garden/farm: bundle ties that don’t crack under UV or cold snaps.

- Construction and daily-use bundling: consistent tensile, fewer kinks.

- Gift/food packaging: clean surfaces, RoHS/REACH-conscious choices.

Quick Specification Snapshot

| Core material | Low-carbon steel (Q195 / SAE 1008), annealed or galvanized core |

| Diameter range (overall) | ≈ 0.5–2.5 mm (custom on request) |

| PVC jacket | Thickness ≈ 0.15–0.35 mm; Shore A 70–90; silver-tone, other colors available |

| Tensile strength | ≈ 350–550 MPa (real-world use may vary by core and process) |

| Zinc coating (if galvanized) | Class per ASTM A641 or EN 10244-2; typical 30–90 g/m² |

| Service life (outdoor) | Around 3–8 years, climate/UV/salt exposure dependent |

Many customers say the finish on Supply High Quality PVC Coated Silver Wire feels “glass-smooth but not slippery.” That sounds subjective—still, it tracks with proper extrusion temperature control.

Process Flow (How Good Wire Gets Made)

- Wire rod selection → drawing to target core diameter.

- Annealing for ductility (if required for bending-rich uses).

- Galvanizing (electro or hot-dip) for corrosion defense.

- Surface prep: degrease + phosphate; improves PVC adhesion.

- PVC extrusion coating → cooling → color stabilization.

- Precision spooling (tension control reduces kinks).

- QC: diameter, adhesion (ASTM D3359-esque), bend cycles, salt-spray (ASTM B117) sampling.

Test Data We Typically See

Adhesion: 4B–5B crosshatch; Salt spray: 72–240 h no red rust (on coated areas); Bend test: ≥16–25 cycles on 180° mandrel without jacket cracks. To be honest, results depend on zinc mass and jacket thickness. Ask for batch reports.

Where It’s Used (A Few Real Scenarios)

- Home/garden bundling ties; staking vines and young trees.

- Bookbinding and craft weaving (aka “Wooden Stick Wire”).

- Construction rebar tag tying, light-duty fastening.

- Gift and food packaging where smooth, clean aesthetics matter.

Vendor Snapshot (What Buyers Compare)

| Vendor | MOQ | PVC Thickness | Lead Time | Certs | Notes |

|---|---|---|---|---|---|

| PeilingTech (Hebei, China) | ≈ 1–3 tons | 0.15–0.35 mm | 10–25 days | ISO 9001; RoHS/REACH on request | Strong craft/garden color range |

| Vendor B | ≈ 5 tons | 0.20–0.40 mm | 20–35 days | ISO 9001 | Good for heavy-gauge orders |

| Vendor C | ≈ 2 tons | 0.12–0.30 mm | 12–28 days | ISO 9001; optional SGS tests | Competitive for custom spools |

Customization Tips

Ask for: target tensile (by application), jacket hardness, exact silver tone (gloss vs. matte), spool weight (to fit your machines), and packaging (film wrap for dust-free gifts work). Short note: Supply High Quality PVC Coated Silver Wire in smaller diameters benefits from a slightly softer jacket for kink resistance.

Mini Case Files

Garden brand (EU): switched to 0.30 mm jacket and UV-stable silver; field returns dropped ≈18% in winter trials. Feedback: “Less cracking, nicer shine.”

Craft wholesaler (US): demanded ultra-smooth spooling for bookbinding; by tightening tension control, jam rate on auto-feeders fell noticeably—operator said “finally quiet.”

Compliance and Standards

- Quality: ISO 9001 systems (supplier-dependent).

- Substances: RoHS/REACH statements available upon request.

- Reference tests: ASTM A641 (galv wire), EN 10244-2 (organic coatings), ASTM B117 (salt spray), ASTM D3359 (adhesion).

Origin: Room 818, Lijing INTL BLDG, No.681 Xinhua Road, Shijiazhuang, Hebei, China. If you want galvanized or plain annealed variants for bundling, they’re in the same family and ship together—handy for mixed orders.

Why This Wire

Smooth surface, bright, consistent color—sounds like brochure-speak, but in practice that’s exactly what reduces snagging and elevates the look for packaging and crafts. That’s why Supply High Quality PVC Coated Silver Wire keeps showing up across industries that care about both performance and appearance.

References

- ASTM A641/A641M – Zinc-Coated (Galvanized) Carbon Steel Wire.

- EN 10244-2 – Steel wire and wire products: Organic coatings on steel wire.

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ASTM D3359 – Measuring Adhesion by Tape Test.

- ISO 9001 – Quality Management Systems; EU RoHS Directive 2011/65/EU; REACH (EC) No 1907/2006.

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025