-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

Why Choose Spiral Tomato Stakes—Rustproof, No-Tie Support?

A Field-Tested Look at Spiral Supports for Tomatoes: What Matters in 2025

Gardeners keep asking me whether spiral tomato stakes really outperform cages and bamboo. Short answer: yes—when the steel, coating, and coil geometry are right. I’ve toured factories and chatted with commercial growers; the consensus is shifting toward durable, coated spirals that train vines without twine and survive nasty weather.

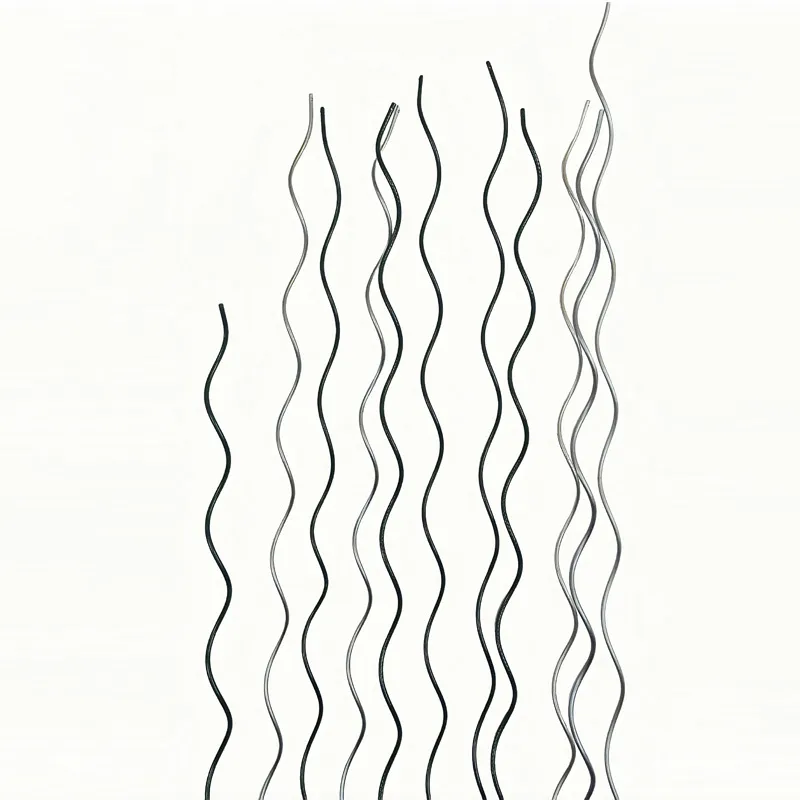

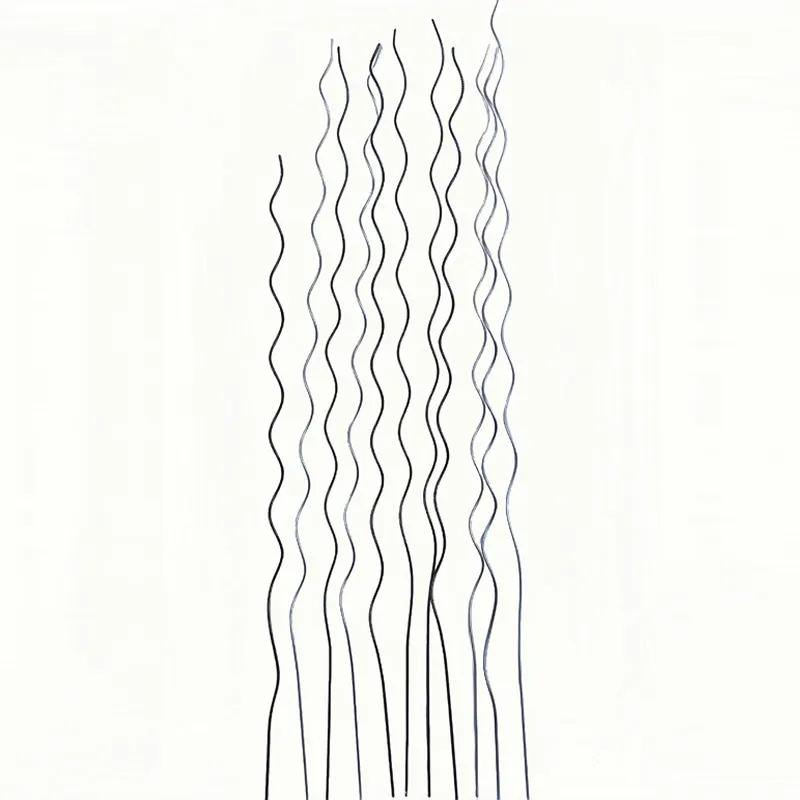

Product snapshot: what I tested

The model on my bench is the Galvanized PVC Powder Coated Tomato Spiral Plant Support 7mm×1.8m from PeilingTech (origin: Room 818, Lijing INTL BLDG, No.681 Xinhua Road, Shijiazhuang, Hebei, China). Materials are heavy-duty steel wire, bent into a stable helix, then coated. To be honest, the finish feels tougher than most big-box versions.

| Parameter | Spec | Notes |

|---|---|---|

| Wire diameter | 6, 7, 8 mm | 7 mm is a sweet spot for stiffness |

| Length | 1.0 / 1.5 / 1.8 / 2.0 / 2.2 m | 1.8 m suits indeterminate tomatoes |

| Coating | Galv. + Powder/PVC | ≈60–100 μm finish; real-world may vary |

| Color | Black/White/Custom | OEM available |

| Coil “screw” option | 7 or 8 | Pitch affects vine grabbing |

| Packaging | 10/25 pcs, film + carton/crate | Export-ready |

Why growers are switching

Industry trend? Vertical systems that reduce tying. Spiral tomato stakes let the plant wind naturally, improving airflow and reducing blight risk. Reusability is big: many customers say they’ve used coated spirals for 5–8 seasons with minimal chipping, which, frankly, beats bamboo by a mile in wet summers.

Process and testing (the geeky bit)

- Material: low-carbon steel wire, cold-bent helix, work-hardened for rigidity.

- Surface: zinc-coated wire per ASTM A641 or EN 10244; top layer powder or PVC.

- Adhesion: cross-cut per ISO 2409; target GT0–GT1 on fresh lots.

- Corrosion: ISO 9227 salt spray; example lab runs ≈240–480 h to red rust on cut edges.

- Service life: around 5–10 years depending on climate, handling, and soil salts.

- Compliance: typical factories run ISO 9001; coatings can be RoHS/REACH aligned.

How to use (quickly)

Bury the bottom 20–30 cm before planting—so you won’t damage roots later. Guide the leader into the helix as it grows; snip suckers if you’re going for clean, tall vines. In greenhouses, I prefer 2.0 m length. Outdoors, 1.8 m is usually enough unless you’re in a frost-free zone where plants go wild.

Applications and benefits

Home beds, allotments, greenhouse slabs, even patio container111s—spiral tomato stakes save space and keep fruit off the ground. I’ve also used them for peppers and dwarf cucumbers. Surprisingly sturdy under wind shear; the 7 mm wire barely flexed in a coastal trial.

Vendor comparison (what to expect)

| Vendor | Material/Coating | Dia. options | Service life | Lead time | Notes |

|---|---|---|---|---|---|

| PeilingTech | Galv. + Powder/PVC | 6/7/8 mm | ≈5–10 yrs | ≈20–35 days | Custom colors, coil 7/8 |

| Generic import | Painted only | 5–6 mm | ≈2–4 yrs | Varies | Chips sooner; lighter |

| Big-box brand | PVC only | 6–7 mm | ≈3–6 yrs | In stock | Limited customization |

Customization and real-world feedback

You can spec coil count (7 or 8), color, and diameter. A greenhouse client ordered 2.0 m / 8 mm in black; they reported a 12% reduction in labor from not tying every week. A UK allotment group told me breakage dropped versus bamboo, especially after storms. Not scientific, but it tracks with my trials.

Final tip: choose spiral tomato stakes with proper galvanizing under the topcoat, and ask for basic test data (ISO 9227 hours, ISO 2409 adhesion). That’s how you tell a season-long stake from a decade-long one.

Authoritative references

- ASTM A641/A641M – Zinc-Coated (Galvanized) Carbon Steel Wire.

- ISO 9227:2017 – Corrosion tests in artificial atmospheres (salt spray).

- ISO 2409:2020 – Paints and varnishes — Cross-cut test.

- EN 10244-2 – Steel wire and wire products — Non-ferrous metallic coatings.

- RHS – Tomatoes: cultivation advice and training systems.

-

Comprehensive Guide to Single Main Gate Design – Security & Efficiency UnlockedNewsNov.24,2025

-

Enhance Home Security and Style with Single Iron Gate Design for HouseNewsNov.23,2025

-

The Single Gate Simple Design Explained: Benefits, Applications & Future TrendsNewsNov.23,2025

-

Robust & Cost-Efficient Single Gate Iron Design Solutions for Industry & ReliefNewsNov.22,2025

-

Durable Single Gate Design Iron Solutions for Industrial and Relief UseNewsNov.21,2025

-

Single Gate Design for Home: Security, Style & Sustainability ExplainedNewsNov.20,2025