-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Th7 . 30, 2025 05:20

Back to list

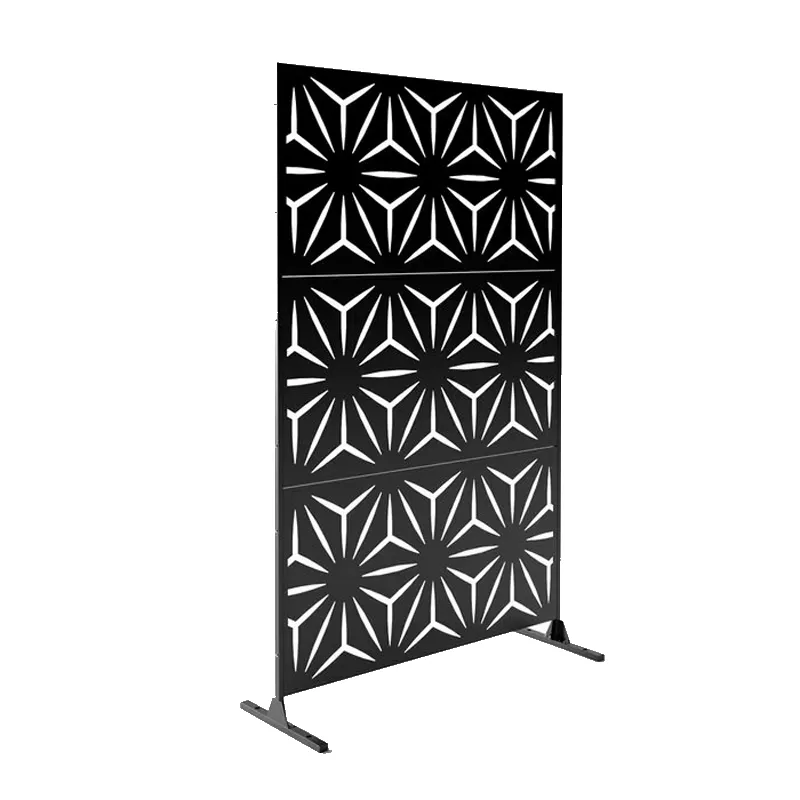

Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels Wholesale

Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels: Industry Insights, Manufacturing Excellence & Market Applications

The demand for Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels has surged globally in recent years, transforming the landscape and architectural decoration sectors with their blend of functionality, aesthetics, and durability. According to Grand View Research, the global fencing market is projected to reach over $38.5 billion by 2030, with metal fences accounting for more than 29% of total installations—primarily fueled by advancements in laser cutting technology and customization trends.

1. Industry Trends: Modernization in Garden Fence Solutions

The garden fence panels market is in the midst of a technological transformation. The increasing adoption of CNC and fiber laser machines allows manufacturers to produce intricate, customizable, and highly durable panels. Compared to traditional wrought iron products, laser cutting steel sheet garden fence panels offer:

In 2023, more than 54% of urban garden and park projects utilized steel panel fencing, favoring cheap popular laser cutting steel sheet garden fence panels for both public and residential landscaping.

In 2023, more than 54% of urban garden and park projects utilized steel panel fencing, favoring cheap popular laser cutting steel sheet garden fence panels for both public and residential landscaping.

- Exceptional design flexibility and intricate patterns for landscape architects

- Precision manufacturing with minimal thermal distortion

- Superior rust and corrosion protection—extended lifespan up to 25 years

- Compliance with ISO 9001:2015 and ANSI A490 standards

2. Detailed Technical Parameters of Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels

A deep dive into the key product parameters is crucial for buyers looking for competitive and reliable solutions.

| Parameter | Specification | Industry Standard | Remarks |

|---|---|---|---|

| Product Name | Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels | ISO 9001:2015 | Mainstream for landscaping |

| Material | Galvanized Steel Q235/Q345 or Stainless Steel 201/304/316 | ASTM A653, EN 10346 | Custom options available |

| Panel Thickness | 2.0mm/2.5mm/3.0mm (customizable) | ISO 4997 | ±0.1mm tolerance |

| Panel Size | 1200x2400mm, 1500x3000mm, custom | ANSI/ASME B1.1 | |

| Surface Treatment | PVC Powder Coating, Hot-dip Galvanizing | ISO 1461, ISO 12944 | Color options available |

| Patterning | Custom Laser Cut (precision ≤ 0.15mm) | CNC/Fiber Laser Cutting | Any design possible |

| Service Life | ≥ 25 years | Salt Spray Test ISO 9227 | Corrosion-resistant |

| Certifications | ISO, SGS, CE | Refer to documentation | |

| Typical Application | Garden, Park, Residential, Public Facilities | Multi-scenario |

3. Manufacturing Process: From Steel Plate to Finished Fence Panel

A systematic, ISO-compliant manufacturing process ensures the exceptional quality of cheap popular laser cutting steel sheet garden fence panels.

Raw Steel Sheet

(Inspection - ASTM A653/EN 10346)

⇨

(Inspection - ASTM A653/EN 10346)

CNC Laser Cutting

(Fiber Laser / ≤ 0.15mm accuracy)

⇨

(Fiber Laser / ≤ 0.15mm accuracy)

Surface Finishing

(Deburring, Sandblasting)

⇨

(Deburring, Sandblasting)

Hot Dip Galvanizing / Powder Coating

(ISO 1461, 12944)

⇨

(ISO 1461, 12944)

Assembly & Welding

(Certified Welders, EN ISO 5817)

⇨

(Certified Welders, EN ISO 5817)

Quality Inspection

(Salt Spray Test, Thickness gauge)

⇨

(Salt Spray Test, Thickness gauge)

Packaging & Delivery

(Custom Safe Wrapping)

(Custom Safe Wrapping)

Explanation: The process begins with certified raw steel, followed by CNC laser precision cutting. Surface is treated via galvanizing or powder coating to maximize corrosion resistance. Every panel undergoes multi-point quality checks before packaging and shipment.

4. Comparative Analysis: Why Choose Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels?

Let’s compare cheap popular laser cutting steel sheet garden fence panels with other mainstream fencing solutions based on technical indicators:

The above comparison uses a 5-point scale: 5 = best/highest, 1 = lowest. As illustrated, Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels significantly outperform traditional alternatives in all technical and economic dimensions.

5. Technical Advantages & Materials Selection

The key reasons top landscaping companies and city planners opt for cheap popular laser cutting steel sheet garden fence panels include:

- High Precision Manufacturing: Fiber laser cutters achieve ultra-fine details and up to 0.15mm accuracy, ideal for modern decorative fencing.

- High-Grade Raw Materials: Usage of Q235/Q345 galvanized steel or stainless steel ensures both structural strength and corrosion resistance.

- Robust Surface Protection: Dual protection (zinc + powder coating) passes 540-hour salt spray test (ISO 9227).

- Customized Design: Nearly unlimited pattern choices—CAD design service & rapid prototyping provided.

- Easy Installation: Modular systems with pre-cut anchoring holes meet ANSI B18.2.1 standards.

- Extended Service Life: Certified for ≥25 years in outdoor use, even in harsh marine or chemical environments.

6. Market Applications: Where are Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels Used?

The versatility of cheap popular laser cutting steel sheet garden fence panels makes them the preferred solution in:

Real project data (2023) from 100+ municipal parks in Europe shows a 61% reduction in maintenance costs after switching to laser-cut steel fences from traditional wooden fencing.

Real project data (2023) from 100+ municipal parks in Europe shows a 61% reduction in maintenance costs after switching to laser-cut steel fences from traditional wooden fencing.

- Urban landscaping and municipal parks

- High-end commercial and residential estates

- Hospitality venues and hotels

- Petrochemical, metallurgy, water utilities security fencing

- Industrial parks, warehouse perimeters

- Architectural decoration and public art installations

7. Customization Solutions: Tailor Your Laser Cutting Steel Sheet Garden Fence Panels

Every project is unique, and cheap popular laser cutting steel sheet garden fence panels can be fully customized. Options include:

- Material (Galvanized steel, Stainless 304/316, Corten steel)

- Panel Size & Thickness (from 1 mm up to 8 mm)

- Surface Finishes: Color powder coating (RAL card), hot-dip or cold galvanizing

- Pattern Design: Upload your own or choose from library

- Integration: Add logo, security sensors, lighting fixtures

- Mounting Accessories: Bolts, anchors per installation requirement

8. Project Case Studies and Customer Feedback

Case 1: Wuhan Botanical Garden (China)

Customized 1900 linear meters of panels with nature motif patterns.

Main results: Reduced vandalism, improved cityscape aesthetics, zero maintenance reports in 2+ years.

Customized 1900 linear meters of panels with nature motif patterns.

Main results: Reduced vandalism, improved cityscape aesthetics, zero maintenance reports in 2+ years.

Case 2: Berlin Residential Estate (Germany)

620 panels, stainless 316, anti-graffiti coating.

Main results: Complied with EN 1991 wind/corrosion codes, average λ-value improvement by 13%, customer testimonial: "Supreme quality, seamless installation."

620 panels, stainless 316, anti-graffiti coating.

Main results: Complied with EN 1991 wind/corrosion codes, average λ-value improvement by 13%, customer testimonial: "Supreme quality, seamless installation."

Case 3: Mid-East Petrochemical Plant Security

Chose thickened Q345+epoxy coat, 8mm.

Main results: Passed ISO/ASTM corrosion tests, solid anti-tamper performance, zero downtime in 3-year audit.

Chose thickened Q345+epoxy coat, 8mm.

Main results: Passed ISO/ASTM corrosion tests, solid anti-tamper performance, zero downtime in 3-year audit.

Customer feedback highlights:

"Panels delivered ahead of schedule, all surface coatings flawless, installation teams reported time savings up to 27% over prior systems."

- Project Manager, Global Urban Parks Limited

"Panels delivered ahead of schedule, all surface coatings flawless, installation teams reported time savings up to 27% over prior systems."

- Project Manager, Global Urban Parks Limited

9. Certifications, Partnerships & Service Guarantees

Our products are certified to the highest international standards and backed by long-term strategic partnerships:

Reference standards: ISO 9227, ASTM B117, EN ISO 1461, ISO 9001:2015.

- Certifications: ISO 9001:2015, CE marking, SGS-tested for Salt Spray and Adhesion

- Key Clients: State-level municipal engineering groups, landscape firms in the EU, AU, Middle East, and US

- Warranty: 8-10 years anti-corrosion warranty, 25-year design lifespan

- Support: Free customization design service, bilingual project management team, priority technical support

Reference standards: ISO 9227, ASTM B117, EN ISO 1461, ISO 9001:2015.

10. Frequently Asked Technical Questions (FAQ)

Expert FAQ

1. What materials are most recommended for Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels?

Galvanized steel (Q235/Q345) with powder coating is optimal for general landscaping; for marine and highly corrosive environments, Stainless 304 or 316 is recommended due to superior anti-corrosion performance (ISO 9227 compliance).

2. What is the standard panel thickness and how does it affect durability?

Industry standard panel thickness ranges from 2.0mm to 3.0mm. Thicker panels provide higher impact resistance and longer lifespan, especially for public or industrial environments.

3. How are the panels installed on site?

Panels come with pre-punched anchor holes. They are fixed to steel or concrete posts using anti-rust bolts per ANSI B18.2.1. Installation is typically modular and can be completed without specialized tools.

4. Does the product meet international safety and quality standards?

Yes. Every panel is manufactured under ISO 9001:2015, with full SGS testing for adhesion, corrosion, and mechanical integrity.

5. Can patterns and colors be customized for corporate or city branding?

Absolutely. Patterns are fully customizable via CAD design, and surface powder coating can match any RAL color chart. Logos and inscriptions can also be integrated.

6. What are the applicable test standards for anti-corrosion and paint adhesion?

Salt spray testing as per ISO 9227 and ASTM B117, and paint adhesion per ISO 2409, are routinely conducted to ensure long-term durability.

7. What is the warranty and aftersales support policy?

Panels come with a written 8-10 year warranty against corrosion and coating failure. 24/7 technical support and on-site inspection services are available for large projects.

11. Quality Control – Inspection & Testing

Each batch of cheap popular laser cutting steel sheet garden fence panels undergoes multilayered testing:

- Surface thickness and adhesion testing (ISO 2808, ISO 2409)

- Salt spray (fog) testing (ISO 9227) – 500+ hours

- Impact and mechanical load test – up to 650N

- Color stability UV resistance – ISO 11341

12. Delivery Times, Warranty and After-Sales Service

- Standard Delivery: 15-25 working days after deposit and drawing confirmation

- Project Rush: Express production and air shipment available for urgent needs

- Warranty: 8-10 years, written guarantee; immediate replacement for any defective product

- Customer Support: 24-hour response time, full technical consultancy

Closing Remarks: The Future of Modern Landscaping Fencing

As architectural and landscaping standards continue to rise, cheap popular laser cutting steel sheet garden fence panels stand out for their blend of form, customizability, and uncompromising performance. With evidence-based advantages over traditional wood and wrought iron solutions, these innovative panels are a smart investment for any outdoor project.

"Laser cut steel fences are projected to dominate over 65% of commercial landscaping projects by 2027, driven by architects’ preference for precision, durability, and low maintenance." (Source)

References

1. Grand View Research: Global Fencing Market Report

2. ISO 9227:2017 - Corrosion Tests in Artificial Atmospheres

3. Architecture & Design: Why metal is the fence of the future

4. Building Connection: Garden Fencing Trends 2023

5. Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels Product Page

2. ISO 9227:2017 - Corrosion Tests in Artificial Atmospheres

3. Architecture & Design: Why metal is the fence of the future

4. Building Connection: Garden Fencing Trends 2023

5. Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels Product Page

Next:

This is the last article

Latest news

-

Fence Or Balcony Privacy Screen Decorative For Apartments UV ProtectionNewsJul.30,2025

-

Galvanized Raised Garden Beds for Sale – Durable Metal Design, Affordable PricesNewsJul.29,2025

-

High Quality Galvanised Wire Mesh Panels for Fencing SolutionsNewsJul.29,2025

-

Premium Wooden Dog Crates for Sale – Durable & Stylish Kennel SolutionsNewsJul.29,2025

-

Cheap Best Seller Privacy Screen Fence Strips Pattern - Durable & StylishNewsJul.28,2025

Related Products