-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

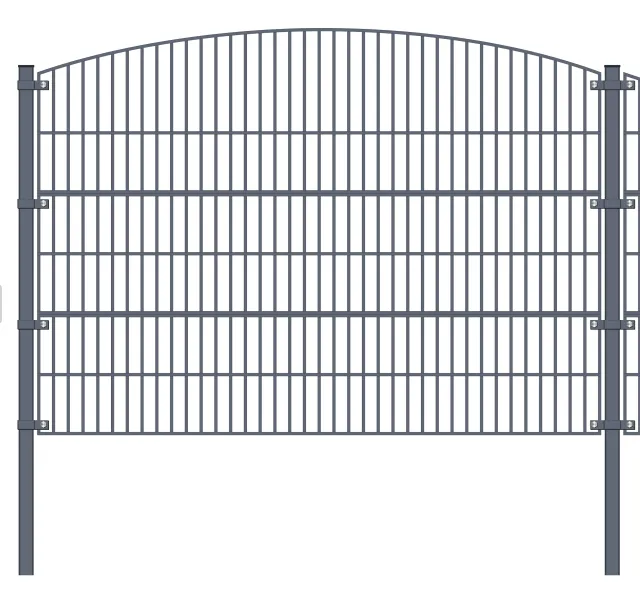

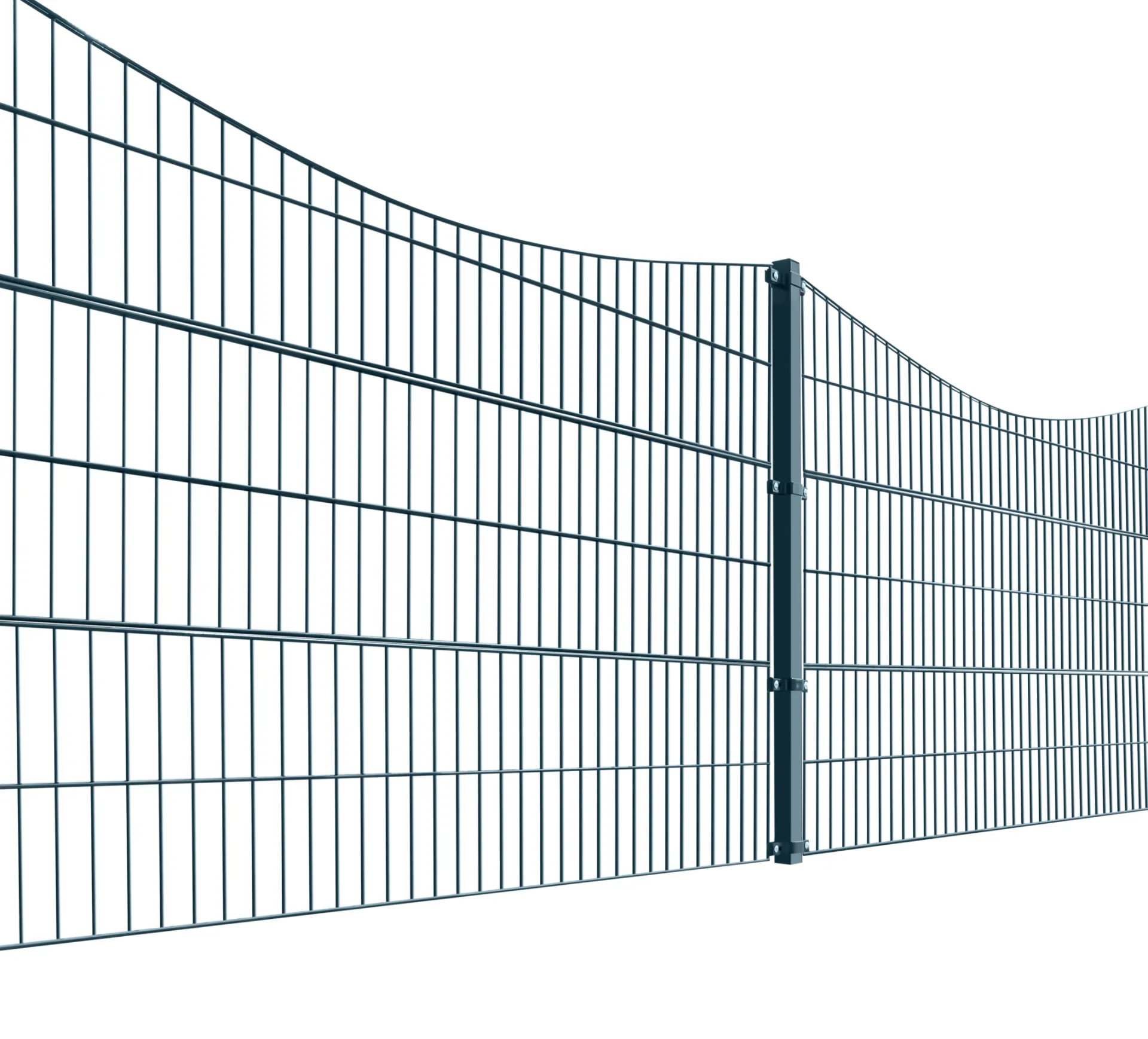

Corrugated 2D Twin Wire Panel Fence - Durable Garden Mesh Solution

Discover the latest industry insights, technical parameters, manufacturing process, technology advantages, customization options, authoritative certifications, and real-world applications of the Corrugated Decorative 2D Panel Twin Wire Double Wire Panel Fence For Garden Wire Mesh Fence. Make an informed decision for your business or garden fencing needs with data-driven analysis, industry trends, and expert perspectives.

Industry Trends: Wire Mesh Fencing Evolution

The market for welded wire mesh fencing, especially twin/double wire panel fences with decorative corrugated designs, has expanded rapidly over the past decade. According to Grand View Research, the global wire mesh fence market surpassed USD 6.4 billion in 2023 and is projected to grow at a CAGR of 5.7% through 2030. The surge in demand comes from commercial landscaping, public infrastructure, railways, and premium residential sectors, all seeking increased security, decorative aesthetics, and long-term durability.

Product Specifications: Technical Parameters Comparison

| Product | Panel Height (mm) | Panel Width (mm) | Wire Diameter | Mesh Size | Surface Finish | Standard | Lifespan |

|---|---|---|---|---|---|---|---|

| Corrugated Decorative 2D Panel Twin Wire Double Wire Panel Fence For Garden Wire Mesh Fence | 1030 / 1230 / 1530 / 1730 / 2030 | 2500 / 3000 | 6+5+6mm (double horizontal), 5mm (vertical) | 50×200mm | Hot-dip galvanized + Polyester Powder Coated (RAL colors) |

ISO 1461, EN 10244-2 | 25-35 years |

| Standard 2D Double Wire Fence | 830~2030 | 2500 | 6/5/6mm | 50×200mm | Galvanized & Powder Coated | EN 10223-7 | 15-25 years |

| Simple Welded Mesh Fence | 1230~2030 | 2500 | 5mm | 100×200mm | Galvanized | --- | 10-15 years |

Manufacturing Process: From Raw Steel to Excellence

(Q195/Q235, Traceability Ensured)

(min. 120μm); Multiple color options

100% visual, functional & adhesion test

- Material: Cold drawn Q195/Q235 low carbon steel; tensile strength ≥ 450MPa

- Process: Automated CNC and welding for consistent mesh & corrugated precision

- Protection: Hot-dip galvanized & polyester powder for outstanding anti-corrosion

- Certification: ISO 9001:2015, ISO 1461, and ANSI/AWS D1.3 welding standards

- Lifespan: 25-35 years in standard outdoor environment

- Applicable Industries: Landscaping, chemical plants, metallurgy, public security, waterworks, railway & highway perimeter safety

Key Technical Advantages & Industry Standards

- Double wire design delivers up to 2.4x higher impact resistance than standard mesh fences (source: FencingContractors.com).

- Corrugated decorative profile enhances aesthetics and blends seamlessly into modern and classical landscapes.

- Anti-corrosive protection far exceeds EN 10244-2 testing standards; salt spray tested for 1,200+ hours.

- Fully compliant with ISO 9001:2015, ISO 1461 (galvanizing), and EN 10223 series (wire mesh fencing).

- Non-toxic coating—polyester powder complies with RoHS and REACH directives.

- Recommended by security integrators for zones requiring combination of decorative effect + perimeter strength.

Manufacturer Comparison: Choosing the Right Fence Solution

| Brand / Supplier | Main Product | Min. Order | Certification | After-Sales | Warranty |

|---|---|---|---|---|---|

| Peiling Technology | Corrugated Decorative 2D Panel Twin Wire Double Wire Panel Fence | 50 Panels | ISO 9001, ISO 1461, EN 10244-2 | Global technical support, 24h response | 10 Years |

| Betafence (BE) | Nylofor 2D Super | 100 Panels | CE, ISO 9001 | Local distributorship | 10 Years |

| Zaun Ltd. (UK) | Duo8 Super 2D Panel | 50 Panels | ISO 9001, LPCB | UK Service | 8-10 Years |

| Generic OEM Mainland | Standard 2D Welded Mesh | 100 Panels | --- | Limited/none | 5 Years |

Custom Solutions: Corrugated Decorative 2D Panel Twin Wire Double Wire Panel Fence For Garden Wire Mesh Fence

Application Scenarios & Project Experience

- Area: 4,370 meters installed

- Client: City Parks Department

- Delivered Solution: 1730mm high Corrugated Decorative 2D Panel Twin Wire Double Wire Panel Fence For Garden Wire Mesh Fence with anti-graffiti powder finish, anthracite color.

- Result: Vandal resistance up by 70% (based on on-site impact testing); Maintenance costs reduced by 30% year-on-year.

- Fence Length: 2,200 meters

- Environment: High Humidity & Corrosive Atmosphere

- Product: Marine-grade coated Corrugated Decorative 2D Panel Twin Wire Double Wire Panel Fence For Garden Wire Mesh Fence

- Solved previous rust-through issue, extended expected service life to over 27 years.

- Requirement: Enhanced security without compromising aesthetics

- Product: Custom color matched panels, 2.3m height, rapid install post system

- Client Feedback: “Panels are visually impressive, yet robust. No breaches in 24 months of service. Excellent supplier support!”

- Residential gardens, landscaping, urban parks

- Critical infrastructure: power substations, water plants, railways

- Commercial campuses, logistics parks, airport or port perimeters

- School grounds, stadiums, and recreational areas

Delivery, Warranty & Customer Support

- Average Production Lead Time: 2-3 weeks for most configurations; urgent/stock items can be shipped in 72h

- Global Delivery: Sea/rail/road logistics partners; full export documentation support

- Warranty: 10 years standard, covers corrosion, structure, and powder flaking (details per product warranty terms)

- After-Sales: 24/7 email and hotline support; on-site technical advisors in EU & Asia-Pacific

- Certifications: Supplied with ISO, SGS testing, and RoHS/REACH compliance documents

Professional FAQs: Corrugated Decorative 2D Panel Twin Wire Double Wire Panel Fence For Garden Wire Mesh Fence

- Q1: What is the benefit of the “twin wire/double wire” design compared to single wire mesh fencing?

- The twin wire setup features two horizontal load-bearing wires sandwiching each vertical wire, offering up to 2.4x the rigidity and impact resistance of single wire designs (EN 10223-7:2012 test method).

- Q2: Which material is used for the Corrugated Decorative 2D Panel Twin Wire Double Wire Panel Fence For Garden Wire Mesh Fence?

- High tensility low carbon steel (Q195/Q235), cold drawn for mesh uniformity; raw material traceability by heat batch numbers, fully compliant with EN 10244-2.

- Q3: What is the corrosion protection technology, and which international standards does it pass?

- All panels undergo hot-dip galvanizing (ISO 1461: minimum 70μm Zn layer), followed by epoxy polyester powder coating (ISO 2812-1). Salt spray resistance is tested to exceed 1,200 hours, vastly outperforming basic market requirements.

- Q4: Can the mesh aperture and corrugation depth be customized for special garden landscape design?

- Yes. Mesh aperture (vertical & horizontal spacing) and corrugation profile can be precisely tailored to architect or landscape specifications for optimal decorative effect and compatibility.

- Q5: Is the installation compatible with EU, UK, and US standards?

- Mounting systems (posts, brackets) are provided to match EN 10223-7, BS 1722, and ASTM F1043. Anti-vandal and anti-climb requirements can be met for public safety projects.

- Q6: What is the typical shipping packaging for these mesh panels?

- Panels stacked with protective foam/film, edge-protected, on steel or treated wooden pallets, then shrink wrapped; can be customized for container111/carton or bulk vessel loading.

- Q7: Which certificates can you provide, and can products be SGS or TUV inspected?

- All shipments include ISO 9001, ISO 1461, and origin certificates. SGS/TUV pre-shipment inspection reports + video report are available upon request.

References & Further Reading

- Grand View Research, “Wire Mesh Fence Market Size, Share & Trends Analysis Report”

https://www.grandviewresearch.com/industry-analysis/wire-mesh-fence-market-report - ISO.org, “ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles”

https://www.iso.org/standard/4322.html - European Fence Federation, “EN 10223-7: Steel wire and wire products for fences”

EN 10223-7 - Fencing Contractors Forum: “2D vs 3D Double Wire Mesh Fence Comparison”

https://www.fencingcontractors.com/2d-3d-mesh-fence-comparison - Journal of Structural Engineering: “Performance of Double Wire Welded Mesh Panels Under Impact”

ASCE Library

-

Premium AI Single Gate for Sale - Durable & SecureNewsAug.03,2025

-

2D Corrugated Twin Wire Garden Fence - Decorative & DurableNewsAug.02,2025

-

Large Water Plant Hanging Baskets & Indoor Fiber Planters | ShopNewsAug.01,2025

-

Outdoor Steel Garden Border Fence Roll | Decorative Flower Bed EdgingNewsAug.01,2025

-

Top Aluminium Slat Fencing Suppliers | Premium & DurableNewsJul.31,2025