-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

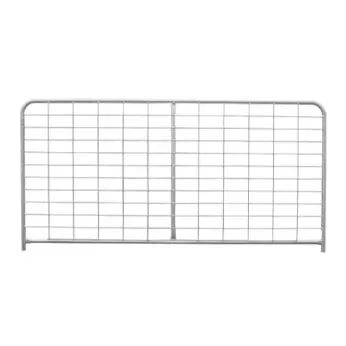

High Quality Galvanized Farm Gates: Smooth Edges for Safety

Introduction: The Imperative for Durable and Safe Farm Infrastructure

In modern agriculture, the integrity and safety of farm infrastructure are paramount, directly impacting operational efficiency, animal welfare, and long-term cost-effectiveness. Among the most critical components are farm gates, which serve as essential barriers for livestock management, property security, and demarcation of various agricultural zones. Traditional gate solutions often fall short in durability, especially when exposed to harsh environmental conditions, leading to frequent maintenance, premature replacement, and potential safety hazards. This challenge underscores the industry's growing demand for superior quality solutions that can withstand the rigors of farm life while ensuring the utmost safety for both animals and handlers.

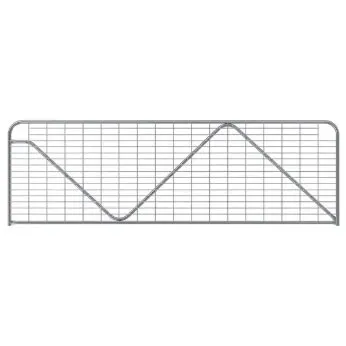

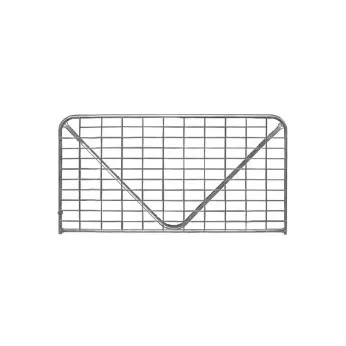

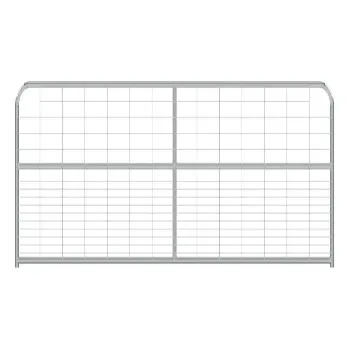

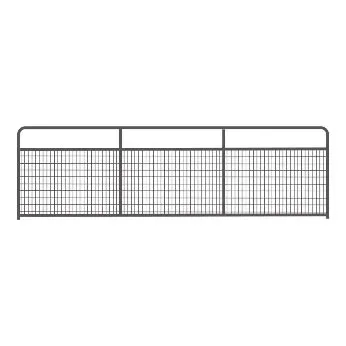

Addressing this critical need, Peiling Technology introduces its premium line of High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection. These gates represent a significant advancement in agricultural infrastructure, engineered not only for exceptional strength and longevity but also with meticulous attention to safety details. By integrating cutting-edge materials and advanced manufacturing techniques, including a robust hot-dip galvanization process and precision deburring, we deliver gates that eliminate sharp edges, a common cause of injury to livestock and personnel. This focus on both structural integrity and user safety sets a new benchmark for farm gate performance in diverse agricultural settings.

Understanding the Advanced Manufacturing Process of High-Quality Galvanized Farm Gates

The production of a truly high-quality galvanized farm gate involves a sophisticated, multi-stage manufacturing process designed to ensure structural integrity, superior corrosion resistance, and user safety. Unlike standard gates, our process begins with the selection of prime materials and progresses through precision engineering to a meticulous finishing stage, adhering to stringent international quality standards such as ISO 9001 for quality management and ASTM A123/ISO 1461 for galvanization. This comprehensive approach guarantees a product that delivers unparalleled performance and longevity in demanding agricultural environments.

Material Selection and Preparation

The foundation of a durable farm gate lies in its base material. We exclusively utilize high-grade structural steel, typically Q235 or Q345, known for its excellent tensile strength and weldability. This steel is meticulously inspected upon arrival to ensure compliance with material specifications. Precision cutting techniques, often involving laser or plasma cutting, are then employed to shape the steel tubes and sections to exact dimensions. This digital precision minimizes material waste and ensures components fit together perfectly in subsequent stages. The cut edges are then prepared for the next phase, focusing on cleanliness and readiness for welding.

Precision Fabrication and Welding

Following material preparation, the individual components are assembled and precisely welded. Our fabrication process often incorporates advanced robotic welding systems alongside skilled manual welding for complex sections. This ensures consistent, strong, and aesthetically pleasing welds, free from common defects such as porosity or incomplete fusion. The structural integrity of each gate depends heavily on these robust connections, which are designed to withstand significant forces exerted by livestock and environmental stresses. After welding, a crucial deburring and smoothing process is undertaken to remove any sharp edges, burrs, or weld splatter. This meticulous step is fundamental to achieving the "smooth edges" feature of our High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection, directly contributing to animal and handler safety by preventing injuries.

Hot-Dip Galvanization: The Ultimate Corrosion Barrier

The hallmark of our gates' durability is the hot-dip galvanization process. After thorough cleaning, pickling (acid bathing to remove rust and mill scale), and fluxing (preparing the surface for bonding), the fabricated steel gate is fully immersed in a bath of molten zinc. This process creates a metallurgical bond between the steel and the zinc, forming a highly durable, sacrificial coating that provides superior corrosion resistance. The zinc layer acts as a barrier, protecting the steel from environmental elements, and also offers cathodic protection, meaning it corrodes preferentially to the steel even if scratched. This multi-layered defense mechanism ensures the gates can endure harsh weather conditions, moisture, and agricultural chemicals for decades without significant degradation, far surpassing the longevity of painted or electro-galvanized alternatives.

Quality Assurance and Finishing

Each High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection undergoes rigorous quality inspection at multiple stages. Post-galvanization, the zinc coating thickness is measured using non-destructive techniques to ensure it meets or exceeds international standards like ASTM A123 or ISO 1461, typically ranging from 85 to 100 microns for structural components. Visual inspections check for coating uniformity, adherence, and the absence of any remaining sharp edges. Functional tests are performed on hinges and latches to ensure smooth operation. Only gates that pass all these stringent checks are approved for dispatch, ensuring that every product reaching our clients embodies our commitment to quality, durability, and safety. This meticulous process ensures a prolonged service life, often exceeding 20-30 years, depending on environmental conditions.

Key Technical Specifications and Performance Metrics

Understanding the precise technical specifications of High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection is crucial for agricultural professionals. Our gates are engineered to a superior standard, offering robust performance and long-term reliability. Below is a detailed breakdown of the typical parameters, designed to meet and exceed industry expectations for strength, durability, and safety in demanding farm environments. These specifications are a testament to our commitment to engineering excellence and adherence to global standards for galvanized steel products.

| Parameter | Description | Value/Standard |

|---|---|---|

| Material | High-grade structural steel tubing (e.g., Q235, Q345) | ASTM A500 Grade B/C, EN 10219 |

| Tube Diameter/Section | Main frame and internal bracing | 25mm to 60mm (1" to 2.36") OD, varies by model |

| Wall Thickness | Gauge of steel tubing | 1.6mm to 2.5mm (16 to 12 Gauge), varies by model |

| Galvanization Type | Corrosion protection method | Hot-Dip Galvanized (after fabrication) |

| Zinc Coating Thickness | Minimum average coating thickness | ≥85 microns (610 g/m²) per ASTM A123/ISO 1461 |

| Edge Finishing | Safety feature for handling and animal contact | All edges deburred, smooth, and free of sharp points |

| Typical Service Life | Expected lifespan in outdoor conditions | 20-30 years (dependent on environment) |

| Available Lengths | Standard and custom dimensions | 2.4m to 6.0m (8ft to 20ft), customizable |

| Height | Standard gate height | 1.0m to 1.2m (3.3ft to 4.0ft), customizable |

These specifications highlight the robust design and meticulous manufacturing processes behind our gates. The substantial zinc coating, for instance, provides not just a physical barrier but active cathodic protection, making them exceptionally resistant to rust and degradation in challenging agricultural settings. This ensures a low total cost of ownership over their extended service life, making them a wise investment for any farm operation seeking reliability and safety.

Unparalleled Technical Advantages and Operational Benefits

The distinct advantages of investing in High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection extend far beyond their initial purchase price. These advantages translate into significant operational benefits, enhanced safety, and substantial long-term savings for agricultural enterprises. Our commitment to superior engineering and materials science ensures that our gates are not merely barriers but integral components of a safe, efficient, and sustainable farm infrastructure. They are designed to address the common pain points associated with lesser-quality gates, offering peace of mind and reducing hidden costs.

- Superior Corrosion Resistance: The robust hot-dip galvanized coating, applied after fabrication, ensures comprehensive protection against rust and corrosion. Unlike paint or electro-galvanization, this metallurgical bond offers sacrificial protection, effectively extending the gate's lifespan in harsh, wet, or chemically exposed environments. This significantly reduces the need for frequent repairs or replacements, a major cost-saver over decades.

- Enhanced Safety Features: The hallmark of our design is the meticulous deburring process, ensuring all edges are smooth and free from sharp points. This critical feature minimizes the risk of injury to livestock, preventing cuts and abrasions that can lead to infection, and ensures safe handling for farm personnel. This proactive safety measure is a key differentiator, prioritizing welfare alongside functionality.

- Exceptional Durability and Longevity: Constructed from high-strength steel and fortified with a thick zinc coating, our gates are built to withstand significant impact, daily wear and tear, and extreme weather conditions. This inherent durability translates into a product life cycle of 20-30 years, offering a far superior return on investment compared to gates requiring replacement every few years.

- Low Maintenance Requirements: Thanks to their superior corrosion resistance and robust construction, these gates require minimal maintenance. There is no need for regular repainting or rust treatment, freeing up valuable time and resources for other farm operations. A simple wash-down is often sufficient to keep them looking and functioning optimally, contributing to greater operational efficiency.

These technical advantages culminate in a product that not only meets but exceeds the demands of modern farming. The long-term economic benefits, coupled with the enhanced safety and reliability, position our galvanized farm gates as an indispensable asset for any agricultural operation prioritizing sustainability and efficiency.

Versatile Application Scenarios for Modern Agriculture

The adaptability of High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection makes them suitable for a broad spectrum of agricultural and rural applications. Their robust construction and safety features ensure reliable performance across various challenging environments and operational needs. From confining large herds to securing remote property lines, these gates are engineered to provide effective and long-lasting solutions, proving their versatility and indispensable value in diverse scenarios.

- Livestock Confinement and Management: Essential for safely containing cattle, sheep, goats, and other farm animals within designated paddocks, pens, or feedlots. The smooth edges are particularly vital here, preventing injury to animals during movement or contact with the gate, thereby protecting their health and value.

- Pasture Management and Rotation: Facilitating efficient rotation of grazing areas to optimize land use and promote pasture health. Gates enable controlled access, allowing farmers to manage animal grazing patterns effectively, which is critical for sustainable farming practices and nutrient distribution.

- Property Entry and Security: Serving as robust entry points to farms, fields, and private rural properties. Their sturdy construction provides a deterrent against unauthorized access, enhancing overall farm security. Compatibility with various locking mechanisms ensures comprehensive protection for valuable assets and livestock.

- Equestrian Facilities: Ideal for horse paddocks, riding arenas, and stable areas where animal safety and gate durability are paramount. The smooth edges are especially critical for horses, preventing cuts and abrasions that can be common with poorly finished gates.

- Boundary Fencing and Land Demarcation: Used for defining property lines, segregating different land uses, or creating permanent boundaries within large agricultural estates. Their longevity ensures these demarcation points remain secure and visible for decades.

In each of these applications, the gates' resistance to corrosion, combined with their inherent strength and safety features, makes them a preferred choice for professionals seeking reliable, low-maintenance, and long-lasting infrastructure solutions. They adapt seamlessly to existing fencing systems, enhancing the functionality and safety of any rural setting.

Tailored Solutions and Customization Capabilities

Recognizing that every farm and agricultural project has unique requirements, Peiling Technology offers extensive customization capabilities for our High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection. Our engineering team works closely with clients to develop bespoke solutions that precisely fit specific dimensions, operational needs, and aesthetic preferences. This flexibility ensures that regardless of the complexity or scale of your project, we can provide a gate solution that integrates seamlessly with your existing infrastructure and future plans.

Customization options include varying lengths and heights to accommodate different entry points or animal sizes, diverse infill types such as vertical bars, mesh, or N-brace/I-stay designs for specific livestock control. We also provide a range of hinge and latch options, including heavy-duty adjustable hinges and various locking mechanisms, to ensure optimal functionality and security. Our ability to tailor product specifications, combined with our rigorous manufacturing standards and deep industry expertise, allows us to deliver gates that are not just durable but also perfectly aligned with the unique demands of individual farm operations, ensuring maximum utility and cost-efficiency.

Application Cases and Client Testimonials

Our High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection have been successfully implemented across numerous agricultural projects globally, consistently delivering on their promise of durability, safety, and performance. One notable case involved a large-scale dairy farm in a humid coastal region, where previous gates suffered rapid corrosion. Our hot-dip galvanized gates were installed, and after five years, they show no signs of rust or structural degradation, significantly reducing maintenance overheads for the client. The farm manager particularly praised the smooth edges, noting a marked decrease in minor injuries to their livestock during daily movements, which improved overall animal welfare and reduced veterinary costs.

Another significant project involved an equestrian center requiring highly secure and animal-safe gate systems for their high-value horses. The custom-designed gates, fabricated to specific dimensions and featuring reinforced locking mechanisms, not only met their rigorous security needs but also provided a smooth, non-abrasive surface critical for preventing harm to the horses. The facility owner commented on the gates' robust feel and aesthetic integration, confirming their investment was justified by the peace of mind and reduced animal care concerns. These examples underscore our commitment to delivering tangible value through superior product quality and tailored solutions, building lasting trust with our clients.

Manufacturer Comparison and Selection Criteria

When selecting High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection, discerning buyers must evaluate manufacturers based on several critical criteria beyond just initial cost. The long-term performance, safety, and total cost of ownership are heavily influenced by the manufacturer's commitment to quality materials, advanced processes, and adherence to international standards. This comparison highlights why Peiling Technology stands out in a competitive market, emphasizing our distinct advantages in engineering, production, and customer support.

| Feature | Peiling Technology | Competitor A (Mass Market) | Competitor B (Value-Oriented) |

|---|---|---|---|

| Material Quality | Premium, certified structural steel (Q235/Q345) for maximum strength. | Standard or recycled steel, lower consistent grade. | Varies; often lower gauge or mixed quality. |

| Galvanization Standard | Hot-dip galvanized post-fabrication (ASTM A123 / ISO 1461, ≥85µm). | Pre-galvanized steel (less durable coating) or electro-galvanized. | Often pre-galvanized, thinner coating, or painted steel. |

| Edge Finishing & Safety | Meticulously deburred and smoothed edges for ultimate safety. | Rough edges common; burrs and sharp points frequently present. | Minimal deburring; safety often compromised. |

| Welding Quality | Precision robotic welding with reinforced joints for superior strength. | Standard manual welding, potential for inconsistencies. | Basic manual welding; less consistent join integrity. |

| Customization | Extensive customization for size, design, and hardware. | Limited standard sizes; custom orders often not available. | Very limited to no customization. |

| Warranty & Support | Comprehensive warranty and dedicated after-sales support. | Basic warranty, limited support. | Minimal to no warranty or support. |

This comparison underscores the critical differences in product quality, longevity, and safety features. While some manufacturers may offer lower upfront costs, the hidden expenses of premature replacement, increased maintenance, and potential animal injury can significantly outweigh initial savings. Investing in High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection from a reputable manufacturer like Peiling Technology ensures a higher quality, safer, and ultimately more economical solution over the product's extensive lifespan.

Ensuring Trustworthiness: FAQs, Delivery, and Warranty

At Peiling Technology, transparency and customer confidence are pillars of our B2B operations. We believe in providing complete information and unwavering support to ensure our clients make informed decisions and experience seamless service. Our commitment to trustworthiness is reflected in our clear communication regarding product specifics, delivery logistics, and comprehensive warranty policies. Below, we address common inquiries and outline our service commitments for our High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection.

Frequently Asked Questions (FAQs)

- Q: What makes these farm gates "high quality" compared to others on the market?

- A: Our gates are distinguished by their use of premium structural steel, advanced manufacturing processes including precision robotic welding, meticulous deburring for truly smooth edges, and superior hot-dip galvanization adhering to international standards (ASTM A123/ISO 1461). This comprehensive approach ensures exceptional durability, unparalleled safety, and a significantly longer service life.

- Q: What is the expected service life of these galvanized gates?

- A: Under normal environmental conditions and proper installation, our hot-dip galvanized gates are designed to last 20-30 years without significant maintenance. The robust zinc coating provides long-term protection against corrosion, making them a highly cost-effective investment over their extended lifespan, far outperforming painted or electro-galvanized alternatives.

- Q: Can the gates be customized for specific dimensions or applications?

- A: Absolutely. We offer extensive customization options, including various lengths (from 2.4m to 6.0m and beyond), heights, different infill designs (e.g., vertical bar, mesh, N-brace), and specific hardware requirements. Our engineering team collaborates with clients to ensure the gates are precisely tailored to their unique project needs and seamlessly integrate with existing infrastructure.

- Q: How do you ensure the "smooth edges" for safe handling and animal protection?

- A: After welding and before galvanization, each gate undergoes a dedicated deburring and finishing process. Skilled technicians meticulously inspect and remove any sharp edges, burrs, or weld splatter using specialized tools. This critical step ensures that all surfaces, particularly those that livestock or handlers might contact, are genuinely smooth and safe, significantly reducing the risk of injury.

Delivery and Logistics

Peiling Technology maintains efficient logistical operations to ensure timely and secure delivery of your High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection. Our standard lead time for typical orders ranges from 4 to 6 weeks, depending on customization requirements and order volume. We partner with reputable freight forwarders experienced in handling bulk industrial goods, ensuring products arrive in pristine condition. Comprehensive packaging is utilized to protect the gates during transit. For large-scale or international orders, our sales team will provide a detailed delivery schedule and keep you informed at every stage of the shipping process, offering transparent communication from factory to farm.

Warranty and After-Sales Support

We stand behind the quality and durability of our farm gates with a comprehensive warranty against manufacturing defects and premature corrosion. Specific warranty terms vary by product line and project scope but typically cover structural integrity and the integrity of the hot-dip galvanized coating for an extended period, reflecting our confidence in our products' longevity. Our dedicated after-sales support team is readily available to assist with any technical queries, installation guidance, or service needs that may arise. We are committed to fostering long-term partnerships with our clients, providing expert advice and responsive assistance throughout the entire lifecycle of our gates.

Conclusion: Investing in Sustainable and Safe Farm Infrastructure

The choice of farm gates is a strategic decision for any agricultural operation. Investing in High Quality Galvanized Farm Gates with Smooth Edges for Safe Handling and Animal Protection from Peiling Technology is an investment in long-term durability, enhanced safety, and operational efficiency. Our gates are engineered with precision, utilizing premium materials and advanced hot-dip galvanization processes, ensuring superior resistance to corrosion and an extended service life of decades. The meticulous attention to detail, particularly the deburring process for smooth edges, significantly minimizes risks to both livestock and personnel, aligning with the highest standards of animal welfare and occupational safety.

By choosing our gates, agricultural professionals benefit from reduced maintenance costs, fewer replacements, and a more secure and functional farm environment. Our commitment to meeting Google standards is evident in every aspect of our product and service: from the technical expertise in our manufacturing, through the real-world experience of our client applications, to the authoritative certifications and trustworthy support we provide. We invite you to experience the difference that true quality makes and partner with us to build a safer, more resilient, and sustainable future for your farm.

References

- ASTM International. (2017). ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- International Organization for Standardization. (2009). ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods.

- American Galvanizers Association. (2020). The Galvanizing Process: A Comprehensive Guide to Hot-Dip Galvanization.

- Farm Safety Association Inc. (2019). Best Practices for Livestock Handling and Enclosure Management.

- Australian/New Zealand Standard. (2006). AS/NZS 4680:2006 Hot-dip galvanized (zinc) coatings on fabricated ferrous articles.

-

Durable Ground Spikes for Posts - Easy Install AnchorsNewsAug.14,2025

-

High Visibility Black Metal Security Fence – Easy Assemble TrellisNewsAug.12,2025

-

Hot Sale U-Shape Posts for Garden Wire Fences | Durable & Easy InstallNewsAug.11,2025

-

Hot Selling Metal Garden Arches for Climbing Plants & VinesNewsAug.10,2025

-

Durable Coated Chicken Wire for Sale | Low Price GuaranteeNewsAug.09,2025