-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 14, 2025 12:32

Back to list

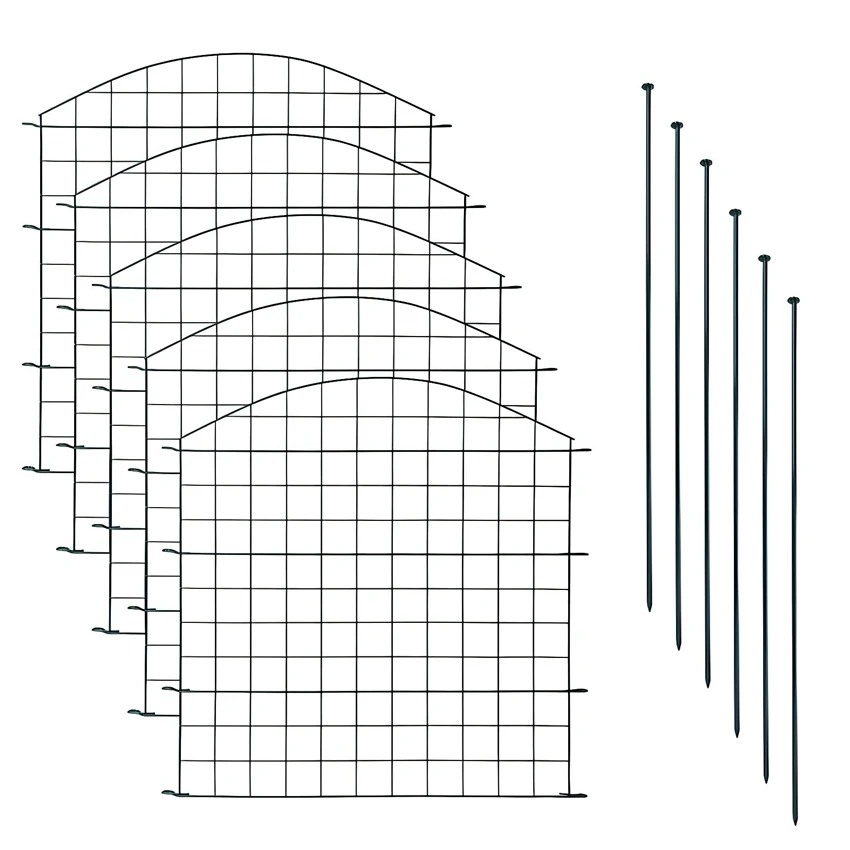

2x2 welded wire panels

2x2 welded wire panels are increasingly popular in various construction and architectural projects due to their versatility, durability, and ease of use. These panels are constructed by welding horizontal and vertical wires into a grid, with each square typically measuring two inches by two inches. The uniformity and strength of the grid provide a multitude of applications, from fencing and shelving to enclosures and trellising. Their myriad utilities make them indispensable for both professional contractors and DIY enthusiasts.

The expertise embedded in producing high-quality 2x2 welded wire panels manifests in their corrosion-resistant coatings and welding precision. Manufacturers utilize galvanizing processes or employ PVC coatings to ensure the panels withstand corrosion, even in humid or saline environments. This extends their usability across diverse climates and conditions, from tropical areas to industrial locales prone to exposure to corrosive elements. Authoritativeness in the field of welded wire panels stems from compliance with industry standards and rigorous quality control. Reputable manufacturers adhere to specifications set by bodies such as ASTM, ensuring that the panels not only meet structural requirements but also safety and environmental standards. Selecting products from these manufacturers offers peace of mind, knowing that each panel’s durability and performance have been validated by authoritative industry benchmarks. Trustworthiness in this context is linked to the transparency and reliability of both the product and its supplier. Customers seeking 2x2 welded wire panels should prioritize vendors who provide detailed product information, customer reviews, and evidence of compliance with industry standards. Trust is further bolstered when suppliers offer warranties or guarantees, reflecting their commitment to quality and customer satisfaction. In summary, 2x2 welded wire panels represent a versatile and reliable option across various sectors, whether for secure fencing, agricultural solutions, or construction reinforcement. Their adaptability, coupled with rigorous manufacturing processes and industry compliance, ensures they meet high standards for durability and performance. This makes them a favored choice for those seeking both functionality and cost-effectiveness without compromising on quality. By understanding the breadth of applications and the expertise behind their production, stakeholders can make informed decisions, maximizing the benefits these panels offer across diverse projects.

The expertise embedded in producing high-quality 2x2 welded wire panels manifests in their corrosion-resistant coatings and welding precision. Manufacturers utilize galvanizing processes or employ PVC coatings to ensure the panels withstand corrosion, even in humid or saline environments. This extends their usability across diverse climates and conditions, from tropical areas to industrial locales prone to exposure to corrosive elements. Authoritativeness in the field of welded wire panels stems from compliance with industry standards and rigorous quality control. Reputable manufacturers adhere to specifications set by bodies such as ASTM, ensuring that the panels not only meet structural requirements but also safety and environmental standards. Selecting products from these manufacturers offers peace of mind, knowing that each panel’s durability and performance have been validated by authoritative industry benchmarks. Trustworthiness in this context is linked to the transparency and reliability of both the product and its supplier. Customers seeking 2x2 welded wire panels should prioritize vendors who provide detailed product information, customer reviews, and evidence of compliance with industry standards. Trust is further bolstered when suppliers offer warranties or guarantees, reflecting their commitment to quality and customer satisfaction. In summary, 2x2 welded wire panels represent a versatile and reliable option across various sectors, whether for secure fencing, agricultural solutions, or construction reinforcement. Their adaptability, coupled with rigorous manufacturing processes and industry compliance, ensures they meet high standards for durability and performance. This makes them a favored choice for those seeking both functionality and cost-effectiveness without compromising on quality. By understanding the breadth of applications and the expertise behind their production, stakeholders can make informed decisions, maximizing the benefits these panels offer across diverse projects.

Previous:

Latest news

-

Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels WholesaleNewsJul.30,2025

-

Fence Or Balcony Privacy Screen Decorative For Apartments UV ProtectionNewsJul.30,2025

-

Galvanized Raised Garden Beds for Sale – Durable Metal Design, Affordable PricesNewsJul.29,2025

-

High Quality Galvanised Wire Mesh Panels for Fencing SolutionsNewsJul.29,2025

-

Premium Wooden Dog Crates for Sale – Durable & Stylish Kennel SolutionsNewsJul.29,2025

-

Cheap Best Seller Privacy Screen Fence Strips Pattern - Durable & StylishNewsJul.28,2025

Related Products