-

-

Whatsapp:+86 17732187393

Whatsapp:+86 17732187393 -

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 19, 2025 08:57

Back to list

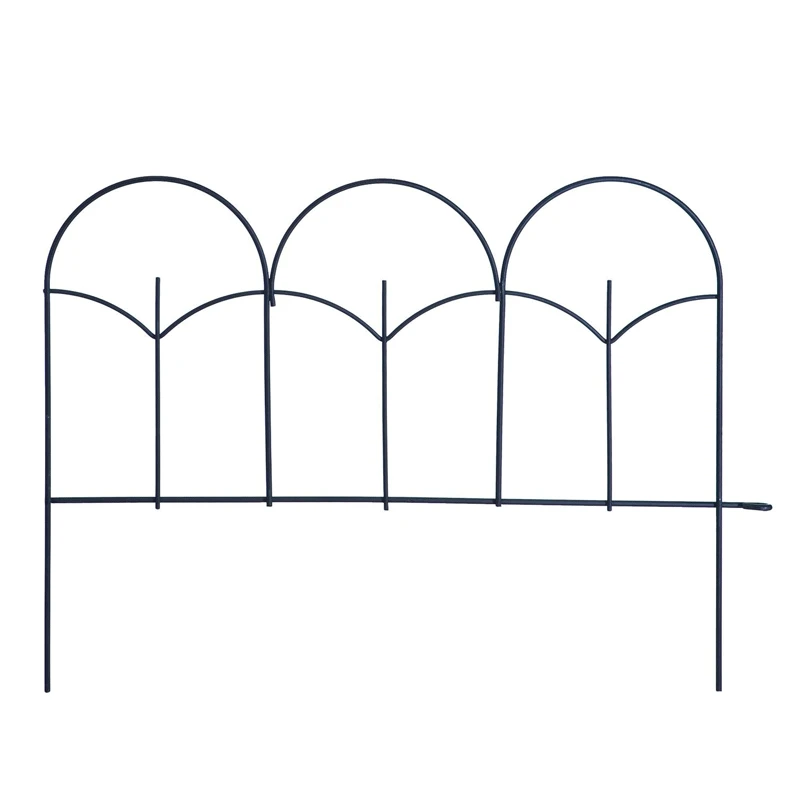

Holland Fence Netting PVC Coated Euro Farm And Garden Wire Mesh

Plastic coated wire panels are revolutionizing the way we think about fencing and structural applications. In an industry where corrosion resistance and durability are paramount, these panels provide an exceptional solution. Combining the strength of metal with the resilience of plastic, they cater to an extensive range of uses from agriculture to architecture.

Security experts often recommend plastic coated wire panels for high-security facilities. The tough, resilient nature of these panels makes them a formidable barrier, perfect for protecting sensitive areas like data centers, airports, and military installations. Their ability to support additional security measures like sensor installations and CCTV attachments makes them indispensable in risk management scenarios. Trust is key when considering plastic coated wire panels, not only among end-users but also from manufacturing and material quality aspects. Reputable manufacturers ensure that their plastic coating process is done to the highest standards, offering warranties that guarantee the longevity and performance of the panels. This dedication to quality is fundamental in building customer trust and maintaining market leadership. In industrial applications, these wire panels prove indispensable. Their unique coating provides a protective layer against industrial chemicals, making them ideal for use in chemical plants and processing facilities. The panels are resistant to wear and tear from regular exposure to corrosive substances, making them a wise investment for long-term operational efficiency. Moreover, in the residential sector, homeowners favor plastic coated wire panels for projects that range from garden fencing to stylish indoor dividers. They provide a layer of safety for homes with children and pets, as the smooth coating and durable structure prevent injuries associated with rough or rusty metal fences. The convenience of a maintenance-free, clean appearance is also a compelling reason homeowners opt for plastic coated wire panels. In conclusion, plastic coated wire panels have emerged as a paramount component across diverse fields thanks to their unmatched fusion of strength, flexibility, and sustainability. Whether for utilitarian purposes or aesthetic inclinations, these panels deliver unparalleled performance, making them an investment in the future that professionals across sectors continue to trust and innovate with, ensuring they remain at the forefront of modern applications.

Security experts often recommend plastic coated wire panels for high-security facilities. The tough, resilient nature of these panels makes them a formidable barrier, perfect for protecting sensitive areas like data centers, airports, and military installations. Their ability to support additional security measures like sensor installations and CCTV attachments makes them indispensable in risk management scenarios. Trust is key when considering plastic coated wire panels, not only among end-users but also from manufacturing and material quality aspects. Reputable manufacturers ensure that their plastic coating process is done to the highest standards, offering warranties that guarantee the longevity and performance of the panels. This dedication to quality is fundamental in building customer trust and maintaining market leadership. In industrial applications, these wire panels prove indispensable. Their unique coating provides a protective layer against industrial chemicals, making them ideal for use in chemical plants and processing facilities. The panels are resistant to wear and tear from regular exposure to corrosive substances, making them a wise investment for long-term operational efficiency. Moreover, in the residential sector, homeowners favor plastic coated wire panels for projects that range from garden fencing to stylish indoor dividers. They provide a layer of safety for homes with children and pets, as the smooth coating and durable structure prevent injuries associated with rough or rusty metal fences. The convenience of a maintenance-free, clean appearance is also a compelling reason homeowners opt for plastic coated wire panels. In conclusion, plastic coated wire panels have emerged as a paramount component across diverse fields thanks to their unmatched fusion of strength, flexibility, and sustainability. Whether for utilitarian purposes or aesthetic inclinations, these panels deliver unparalleled performance, making them an investment in the future that professionals across sectors continue to trust and innovate with, ensuring they remain at the forefront of modern applications.

Latest news

-

Cheap Popular Laser Cutting Steel Sheet Garden Fence Panels WholesaleNewsJul.30,2025

-

Fence Or Balcony Privacy Screen Decorative For Apartments UV ProtectionNewsJul.30,2025

-

Galvanized Raised Garden Beds for Sale – Durable Metal Design, Affordable PricesNewsJul.29,2025

-

High Quality Galvanised Wire Mesh Panels for Fencing SolutionsNewsJul.29,2025

-

Premium Wooden Dog Crates for Sale – Durable & Stylish Kennel SolutionsNewsJul.29,2025

-

Cheap Best Seller Privacy Screen Fence Strips Pattern - Durable & StylishNewsJul.28,2025

Related Products